The remarkable strength-to-weight ratio and high corrosion resistant properties of titanium has resulted in the ever growing use of this important engineering material in many demanding sectors, not least the global aerospace industry.

The production of critical structural parts from titanium ensures their required performance and reliability whilst significantly reducing components mass. Although relevant to all users of titanium, the enhanced strength and reductions in weight that the material delivers are of particular importance to the aerospace industry, as these advantages improve the aircraft’s’ performance and increase fuel economy.

The negative trade-offs produced by the use of titanium are the many problems uncounted for when machining this difficult-to-cut material. When used in metalworking industries, the word titanium normally relates not only to pure titanium but also to titanium alloys. In accordance with metallurgical properties, depended on the present elements, there are several groups of titanium: commercially pure titanium (unalloyed), α-, β-, α-β- and other alloys. It is sometimes stated that titanium machinability is similar to that of austenitic stainless steel. This proposition is more or less true if it relates to commercially pure titanium, although it is totally wrong with respect to treated α-β- and especially β-titanium alloys.

The negative trade-offs produced by the use of titanium are the many problems uncounted for when machining this difficult-to-cut material. When used in metalworking industries, the word titanium normally relates not only to pure titanium but also to titanium alloys. In accordance with metallurgical properties, depended on the present elements, there are several groups of titanium: commercially pure titanium (unalloyed), α-, β-, α-β- and other alloys. It is sometimes stated that titanium machinability is similar to that of austenitic stainless steel. This proposition is more or less true if it relates to commercially pure titanium, although it is totally wrong with respect to treated α-β- and especially β-titanium alloys.

Machinability rating depends heavily on the type of titanium and its treatment. The machinability of the widely used annealed titanium TiAl6V4 is approximately 35-40% less than annealed stainless steel AISI 304. However, if we take the machinability of the aforementioned titanium grade as 100%, the so-called triple 5, titanium 5-5-5-3, a major manufacturing headache for many machine shops, features machinability characteristics that are twice as difficult.

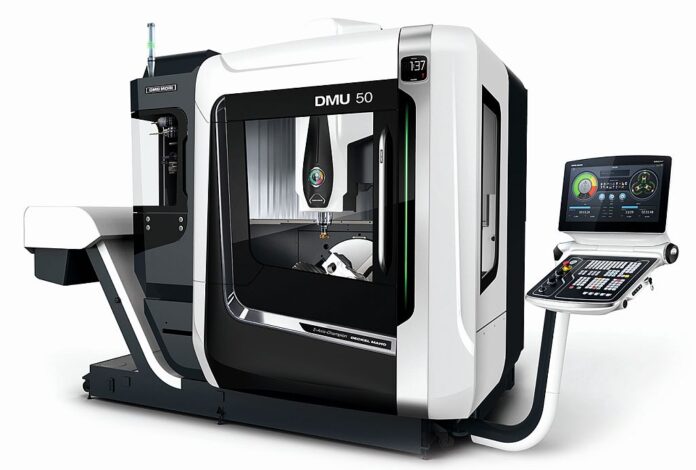

Machine tool manufacturers continue to introduce innovations and developments that make the cutting of titanium more effective. Modern machine tools allow operators to apply advanced machining strategies and to employ one-hit production methods. However, the typically low cutting speeds used in the machining of titanium severely limits machine tools’ efficiency potential and results in the cutting tool becoming the weakest element of the whole technical production system. In short, the cutting tool determines the productivity boundaries when machining titanium, and as such, has become a major factor in the quest for a radical improvement of this situation.

Due to the low thermal conductivity of titanium, the main problem in cutting this material is the generation of heat. Poor heat transfer leads to considerable thermal loads being directly transferred to the tools cutting edge. Also, less of a problem when machining steel, titanium’s modulus of elasticity contributes to vibration during cutting, as a result, surface finish and accuracy problems can be encountered.

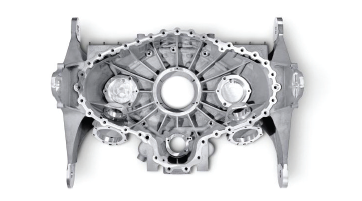

Cutting tool producers continue to place a greater emphasis on developing progressive tools for the efficient machining of titanium. Manufacturing titanium parts is a process with significant buy-tofly ratio, when a large amount of metal needs to be removed. The eventual weight of a finished titanium part may be only 10%, or less of the original weight of a workpiece. Frequently, these parts will have cavities, pockets and ribs that dictate milling as the main method for manufacturing. As a consequence, every new tool that is intended for the milling of titanium creates intense interest amongst the global technical community. Therefore, the latest products from ISCAR, an acknowledged innovator in the field, always attract the attention of the world’s manufacturers involved in machining titanium.

Cutting tool producers continue to place a greater emphasis on developing progressive tools for the efficient machining of titanium. Manufacturing titanium parts is a process with significant buy-tofly ratio, when a large amount of metal needs to be removed. The eventual weight of a finished titanium part may be only 10%, or less of the original weight of a workpiece. Frequently, these parts will have cavities, pockets and ribs that dictate milling as the main method for manufacturing. As a consequence, every new tool that is intended for the milling of titanium creates intense interest amongst the global technical community. Therefore, the latest products from ISCAR, an acknowledged innovator in the field, always attract the attention of the world’s manufacturers involved in machining titanium.

Tool material is of fundamental importance in the success of cutting tools, especially for use when indexable milling difficult-to-cut aerospace materials, in particular titanium. Within this challenging field, ISCAR has developed a new carbide grade IC840. The word new relates to all grade elements: IC840 is characterized by a newly cemented carbide substrate and an innovative hard PVD coating. The grade substrate is highly resistant to thermal cracks; the bronze-color, chocolate, coating boasts high oxidation and chipping resistance; whilst an advanced post-coating treatment improves overall toughness. The advantageous combination of the above IC840 provides users with great opportunities in milling titanium. ISCAR believes that the new chocolate will definitely suit the taste of the manufacturer of titanium components and increase the performance of indexable cutters.

As previously mentioned, milling titanium usually involves removing considerable stock. True workhorses in this field are extended flute indexable tools (porcupines) that are intended for the rough cutting of deep pockets, cavities and wide edges. For these operations, ISCAR has developed the HELITANG H490, a family of advanced milling tools with tangentially clamped inserts, and also the MILLSHRED P290, a range of milling tools carrying serrated inserts that provide an efficient chip splitting (even chip chopping) effect. In addition, the company offers HELITANG FIN, a family of tangential porcupines that was designed especially for semi-finish milling.

ISCAR has recently introduced a new group of extended flute shell mills related to the proven and popular HELIQUAD family. These mills carry one-sided square inserts, which are clamped radially. Why has the company, so well known for its commitment to innovative advantageous cutting geometries, equipped the new mills with traditional simple square inserts? The deceptively simple, new extended flute tools feature a well-designed structure resulting in significantly improved dynamic rigidity and anti-vibration strength. In addition, radial insert clamping enables the inclusion of a chip gullet with a generous volume that answers the requirements of free chip flow when milling at high metal removal rates (MRR). Also, the tools of more popular diameters have internal channels, which are specially designed for machining with a high-pressure coolant (HPC) supply. Even these simple square inserts are characterized by a progressive cutting geometry that provides effective titanium milling.

Hence, if HELITANG H490 and MILLSHRED P290 are intended for productive roughing, and HELITANG FIN for qualitative semifinishing of titanium workpieces, the new HELIQUAD (real HELIQUAD) extended flute shell mills from an application point of view and provides high-efficiency milling with resulting surface conditions close to semi-finish conditions.

ISCAR recently introduced the Ti-TURBO family of solid carbide endmills in a diameter range of 6 to 20mm. The new family was designed for finishing operations and also for high-speed machining (HSM) of mainly slots, with the use of the trochoidal technique. Trochoidal milling features a small width and significant depth of cut, combined with a tool path dictated by a trochoid curve. Under such conditions the tool slices metal up at a high rate. An engagement angle here is small and produced chips are very thin. This results in dramatically decreasing the thermal load on the tool. Ti-TURBO endmills, of unique patent design, have 7 or 9 variable flutes with variable angular pitch (similar to the beneficial CHATTERFREE solid carbide tools) that ensures powerful resistance to vibration. That is why the new family is regarded to as a true turbo booster in the area of titanium milling.

ISCAR recently introduced the Ti-TURBO family of solid carbide endmills in a diameter range of 6 to 20mm. The new family was designed for finishing operations and also for high-speed machining (HSM) of mainly slots, with the use of the trochoidal technique. Trochoidal milling features a small width and significant depth of cut, combined with a tool path dictated by a trochoid curve. Under such conditions the tool slices metal up at a high rate. An engagement angle here is small and produced chips are very thin. This results in dramatically decreasing the thermal load on the tool. Ti-TURBO endmills, of unique patent design, have 7 or 9 variable flutes with variable angular pitch (similar to the beneficial CHATTERFREE solid carbide tools) that ensures powerful resistance to vibration. That is why the new family is regarded to as a true turbo booster in the area of titanium milling.

ISCAR’s MULTI-MASTER versatile line of assembled tools with replaceable solid carbide cutting heads, has been recently enhanced by the introduction of new, six-flute, fast feed milling heads with central coolant holes. The ultra-fine grain carbide substrate of the heads, protected by the advanced AL-TEC coating technology, provides outstanding wear resistance and toughness. The heads are used in productive high feed milling (HFM), resulting in significant reductions in the cycle times of roughing operations.

Manufacturers of titanium parts are constantly placing new demands on cutting tool producers. In order to meet these challenges, cutting tool producers are forced to think out of the box on a regular basis. ISCAR’s prolific R&D team continues to cooperate with many of the world’s leading manufacturers of titanium parts to ensure that the company retains its lead within this challenging sector.

For more information, contact Iscar South Africa – Tel: (011) 997-2700.

Compact, highly dynamic, high-precision 5-axis HSC machine with counter bearing and special Röders geometry compensation.

Compact, highly dynamic, high-precision 5-axis HSC machine with counter bearing and special Röders geometry compensation.

To further ensure ideal geometry and accuracy, the a120nx has a number of systems in place to manage the heat generated by rapid traverse of 2,126 inches per minute. For one, the ballscrews are core-cooled in all axes to give consistent accuracy during continuous production. Moreover, the ballscrews are all dual supported and pre-tensioned to ensure unparalleled dynamic positioning repeatability. Feature-to-feature movement distances on large parts are typically much greater, so rapid traverse rates were increased for the a120nx in order to cover these expansive distances quickly.

To further ensure ideal geometry and accuracy, the a120nx has a number of systems in place to manage the heat generated by rapid traverse of 2,126 inches per minute. For one, the ballscrews are core-cooled in all axes to give consistent accuracy during continuous production. Moreover, the ballscrews are all dual supported and pre-tensioned to ensure unparalleled dynamic positioning repeatability. Feature-to-feature movement distances on large parts are typically much greater, so rapid traverse rates were increased for the a120nx in order to cover these expansive distances quickly. Chip and coolant management features are often overlooked and result in interrupted operations, increased labor costs, machine damage, part-quality issues and reduced tool life. The a120nx enables shop owners to avoid these challenges with supplementary management features, including a sloped surface to remove obstacles between the workpiece and an external chip conveyor, letting chips fall freely. The trough design facilitates rapid chip and coolant evacuation and reduces maintenance needs with a solid panel Z-axis cover design. A standard cyclonic filter provides ultra clean coolant to the through spindle coolant pump and acts as a secondary coolant filter, polishing coolant in the main tank.

Chip and coolant management features are often overlooked and result in interrupted operations, increased labor costs, machine damage, part-quality issues and reduced tool life. The a120nx enables shop owners to avoid these challenges with supplementary management features, including a sloped surface to remove obstacles between the workpiece and an external chip conveyor, letting chips fall freely. The trough design facilitates rapid chip and coolant evacuation and reduces maintenance needs with a solid panel Z-axis cover design. A standard cyclonic filter provides ultra clean coolant to the through spindle coolant pump and acts as a secondary coolant filter, polishing coolant in the main tank.

The negative trade-offs produced by the use of titanium are the many problems uncounted for when machining this difficult-to-cut material. When used in metalworking industries, the word titanium normally relates not only to pure titanium but also to titanium alloys. In accordance with metallurgical properties, depended on the present elements, there are several groups of titanium: commercially pure titanium (unalloyed), α-, β-, α-β- and other alloys. It is sometimes stated that titanium machinability is similar to that of austenitic stainless steel. This proposition is more or less true if it relates to commercially pure titanium, although it is totally wrong with respect to treated α-β- and especially β-titanium alloys.

The negative trade-offs produced by the use of titanium are the many problems uncounted for when machining this difficult-to-cut material. When used in metalworking industries, the word titanium normally relates not only to pure titanium but also to titanium alloys. In accordance with metallurgical properties, depended on the present elements, there are several groups of titanium: commercially pure titanium (unalloyed), α-, β-, α-β- and other alloys. It is sometimes stated that titanium machinability is similar to that of austenitic stainless steel. This proposition is more or less true if it relates to commercially pure titanium, although it is totally wrong with respect to treated α-β- and especially β-titanium alloys. Cutting tool producers continue to place a greater emphasis on developing progressive tools for the efficient machining of titanium. Manufacturing titanium parts is a process with significant buy-tofly ratio, when a large amount of metal needs to be removed. The eventual weight of a finished titanium part may be only 10%, or less of the original weight of a workpiece. Frequently, these parts will have cavities, pockets and ribs that dictate milling as the main method for manufacturing. As a consequence, every new tool that is intended for the milling of titanium creates intense interest amongst the global technical community. Therefore, the latest products from ISCAR, an acknowledged innovator in the field, always attract the attention of the world’s manufacturers involved in machining titanium.

Cutting tool producers continue to place a greater emphasis on developing progressive tools for the efficient machining of titanium. Manufacturing titanium parts is a process with significant buy-tofly ratio, when a large amount of metal needs to be removed. The eventual weight of a finished titanium part may be only 10%, or less of the original weight of a workpiece. Frequently, these parts will have cavities, pockets and ribs that dictate milling as the main method for manufacturing. As a consequence, every new tool that is intended for the milling of titanium creates intense interest amongst the global technical community. Therefore, the latest products from ISCAR, an acknowledged innovator in the field, always attract the attention of the world’s manufacturers involved in machining titanium. ISCAR recently introduced the Ti-TURBO family of solid carbide endmills in a diameter range of 6 to 20mm. The new family was designed for finishing operations and also for high-speed machining (HSM) of mainly slots, with the use of the trochoidal technique. Trochoidal milling features a small width and significant depth of cut, combined with a tool path dictated by a trochoid curve. Under such conditions the tool slices metal up at a high rate. An engagement angle here is small and produced chips are very thin. This results in dramatically decreasing the thermal load on the tool. Ti-TURBO endmills, of unique patent design, have 7 or 9 variable flutes with variable angular pitch (similar to the beneficial CHATTERFREE solid carbide tools) that ensures powerful resistance to vibration. That is why the new family is regarded to as a true turbo booster in the area of titanium milling.

ISCAR recently introduced the Ti-TURBO family of solid carbide endmills in a diameter range of 6 to 20mm. The new family was designed for finishing operations and also for high-speed machining (HSM) of mainly slots, with the use of the trochoidal technique. Trochoidal milling features a small width and significant depth of cut, combined with a tool path dictated by a trochoid curve. Under such conditions the tool slices metal up at a high rate. An engagement angle here is small and produced chips are very thin. This results in dramatically decreasing the thermal load on the tool. Ti-TURBO endmills, of unique patent design, have 7 or 9 variable flutes with variable angular pitch (similar to the beneficial CHATTERFREE solid carbide tools) that ensures powerful resistance to vibration. That is why the new family is regarded to as a true turbo booster in the area of titanium milling.