By Barry Page, Sales Manager, Amada – Johannesburg

The ever-growing need for streamlined production has resulted in companies looking for unique methods of manufacturing with faster production times, less human intervention and ultimately less cost. Labour costs play a massive role in production and the faster a product can be produced, the better the profits.

In the sheet metal industry, this is a difficult target, due to the various stages of production required such as designing, programming, blanking, bending, welding, grinding, painting, assembly, testing and packaging. These various processes are each a headache on their own.

Automation plays a big role in streamlining processes of manufacturing by simplifying processes as well as reducing human intervention.

Blanking – Beginning with the blanking process, the designer needs to have a good understanding of the completed product and its intended use or application. This person also needs to have a good understanding of the machinery being used as well as their distinctive capabilities. They also need to understand the materials being used in the manufacturing process.

The automation process begins in the office with the use of a CAD drawing system. Rendering a 3D model in Amada’s Sheetworks 3D software, the full product can be viewed, operated / animated and broken down into single part items. One drawing is now able to program either the punching, bending or laser operation without having to duplicate anything, thus already saving manpower and effort. This process eliminates trial production and the waste of materials, time and resources.

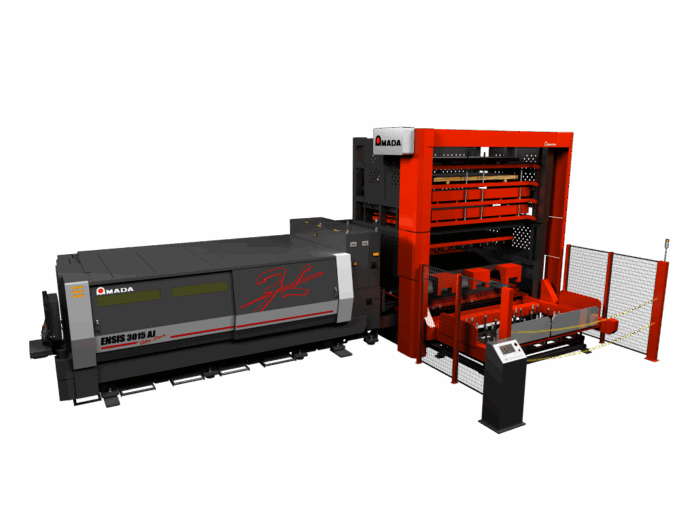

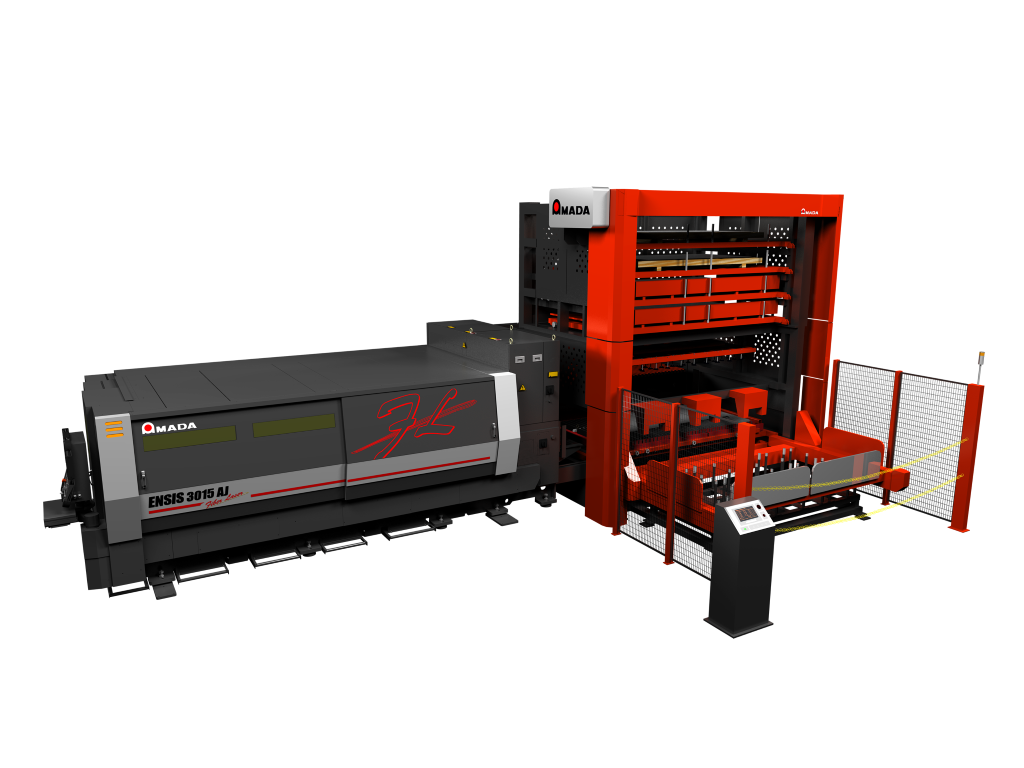

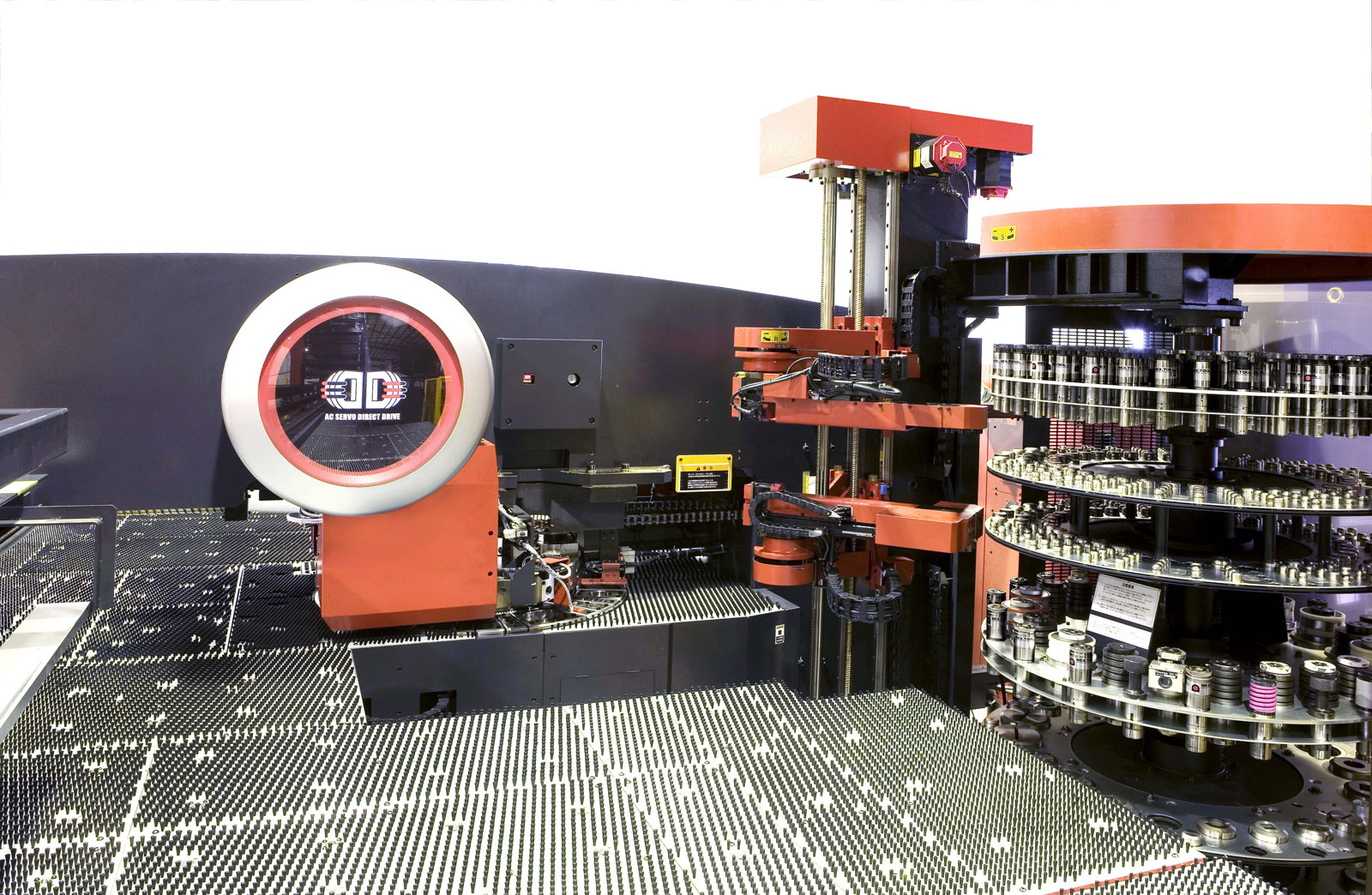

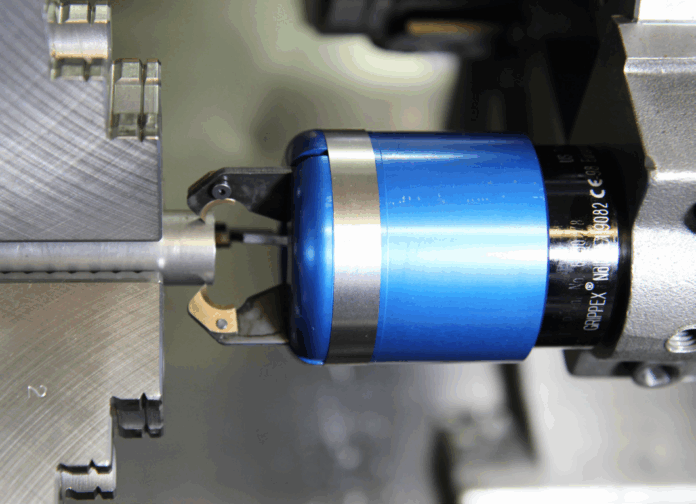

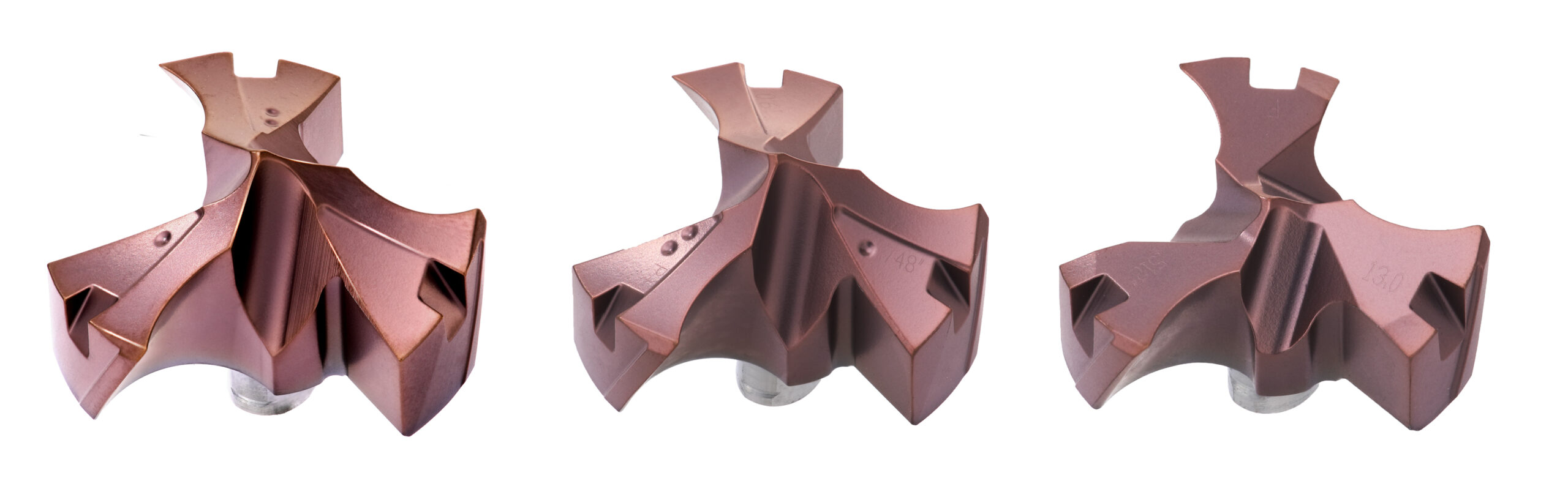

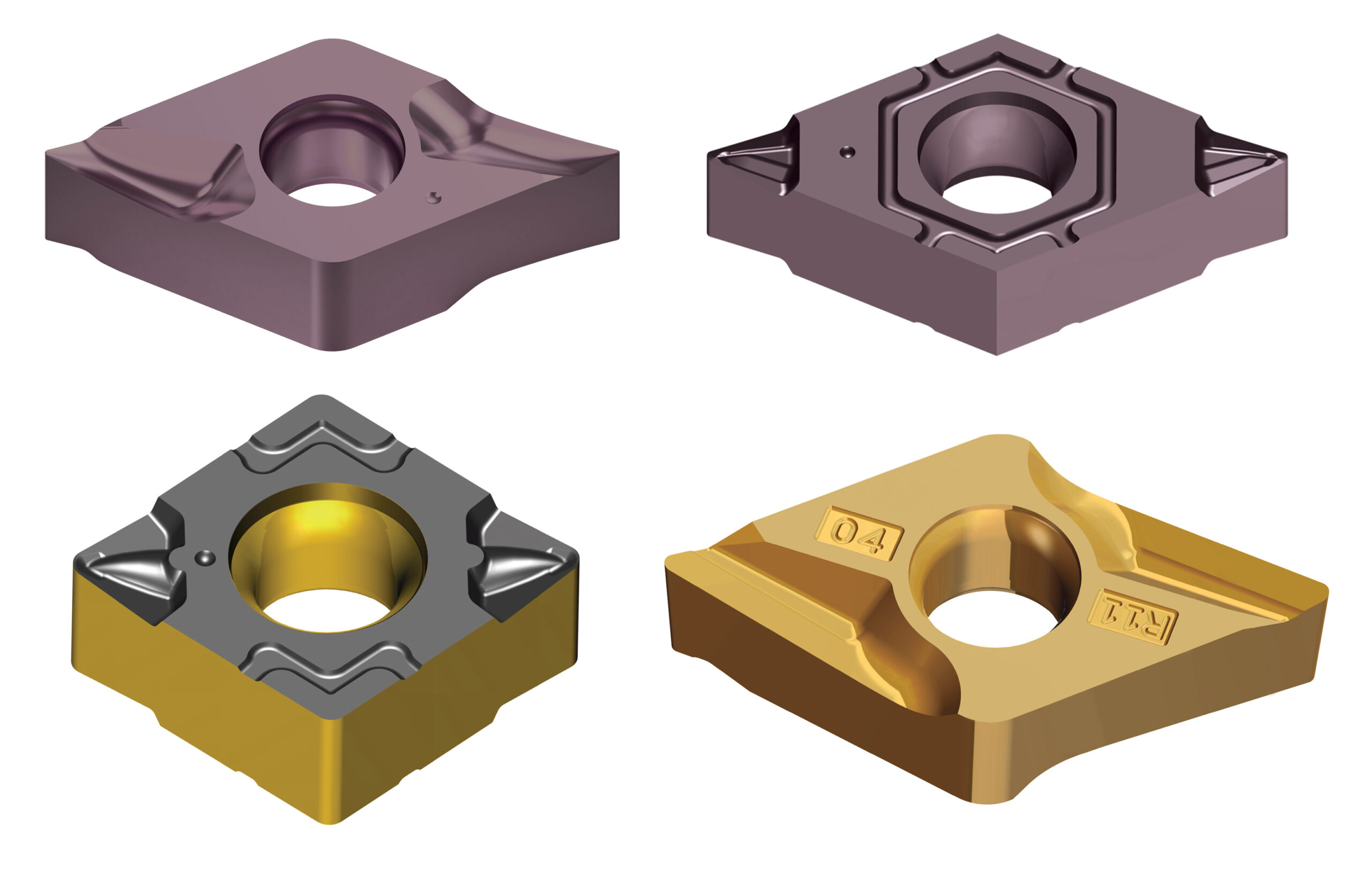

Automated tool change & setup – The options of the Amada PDC (Punch & Die Changer)- holding up to 220 different tools each with 2 dies or the TSU (Tool Storage Unit) – holding up to 300 tools each with 2 dies, will automate the loading and unloading of tooling between jobs on the punching machines or laser / punch combination machines.

The tooling is scanned when loaded into the “magazine”, thus tying it up with the programming software. Each time a tool is selected to be loaded, it is again scanned by the machine to ensure it is the correct tool and at the correct orientation before loading into the turret. The human error factor is thus eliminated.

Automatic tool hit count on the blanking machine will notify the operator when the tool is due to be re-sharpened, ensuring continuous quality production.

Proto-typing – Ultimately, all proto-typing can be done on a PC in the 3D environment, allowing the customer to sign off for the start of production before a single part or sample is physically produced. The process from creating the drawing to tool fitting and programming and simulating is executed by a few clicks on the PC mouse. The automated system will then separate material types and material thicknesses, it will nest the parts according to the quantities required and parameters set, then it will program the layout accordingly for the selected blanking machine.

Easy program transfer – Once completed at the programming stage, the programs are transferred from the database to the machine control by means of a job card with a bar code attached. The use of a bar code scanner at the machine control will instantly display the program and render it immediately available for production to commence.

The scanning of the barcode will ensure that production throughput is handled in the correct sequence as required, thanks to the ability of the programmer who creates a production schedule according to assembly or delivery needs.

Automated machine attendance – Once ready to begin with the actual production, there is an additional automation option for material storage and material handling, too. These automation (retrofittable) systems – ASFH or ASR (Tower Storage Systems) and MPL (Material Manipulation System) are capable of loading the raw material sheets onto the table of the blanking machine after confirming the sheet thickness, ready for production to begin. All of this is possible without the operator having to touch the sheet.

Automated sheet removal / part sorting – Once the sheet has been processed, it is off-loaded by means of the manipulator system. It then is either stacked on a pallet, complete with skeleton and parts or it can be separated by means of a “TK” system. This “TK” (Take Out) system is ideal for the removing and sorting of cut parts from a nested sheet. The part “picker” will remove each individual part from the skeleton by means of numerous individually controlled suckers and will place them onto different stacking pallets, thus sorting parts for different customers or for different secondary processes. Different customers’ parts that were nested together on one sheet can easily be sorted without any human intervention. Continuous, unmanned production is now possible around the clock.

Repeat production of the same components is simplified, thanks to the electronic storage of all machinery setup data in the VPSS database, processing sequences, tooling requirements and bending data are all stored for future need.

Once the blanking process is taken care of, it becomes a bending issue. This is where the final products’ appearance and appeal will come to light.

Bending automation – Bending can also be automated according to the customers’ needs by utilizing Amada’s VPSS4ie Bend Software and creating all bending programs from the initial 3D drawing that was used in the blanking process. Sequencing and tool fitting is done on the PC automatically and allows for human intervention / over-ride. Program simulation on the PC eliminates trial bending on the machine. The “teach’ function on the control of the bender will assist and indicate the precise positioning of each tool as required, while prompting the operator through the bending process.

Automated tool load / unload – In the case of the ATC (Automatic Tool Changer), the machine will automatically load and unload tooling as required for the bending job at hand. The ATC automated tool placing function will drastically reduce setup times between jobs as it can load a full three meters of top and bottom tooling in just 3 minutes.

Suddenly the small batch production runs or single part production becomes a different game and a faster process with far less down- time.

Robotic bending – For long constant production runs, robotics are available to replace operators, thus ensuring continuous around the clock bending. The robotics are ideal for constant bending of the same parts or very large production runs. These systems are available in a variety of sizes of machine capacities, from the very small robotic systems on the EGB press brakes, right up to the large, heavy duty press brakes handling parts that are too heavy for the operator.

The age old saying goes, “every sport has its injuries” and this saying bodes so true in the production environment of a busy workshop. Traceability and accountability is the next headache and is key to any successful production system.

Automatic production feedback & traceability – Amada can now also offer their “My V-Factory” production monitoring software package. This monitoring system is linked to the Amada equipment on the shop floor and provides feedback on the status of the equipment being used. Things like production times, set-up times, alarm times and stand-by times are all recorded and allow constant monitoring of the productivity of individual machines. Continuous problems can be identified and attended to, in order to streamline production.

The remote log-in from an authorized mobile device allows authorized personnel to stay up to date and to keep customers updated on the progress of their production when deadlines are tight.

The remote log-in from an authorized mobile device allows authorized personnel to stay up to date and to keep customers updated on the progress of their production when deadlines are tight.

Automatic satisfaction – All equipment supplied by Amada is designed, developed and fully supported by Amada directly. The Japanese ethos of quality and reliability resonates through the thousands of machines supplied and hundreds of satisfied customers around the world.

With this total solution, ONE company supplies everything, all support is in-house and everything is programmed through a central Amada data-base (VPSS4ie).

Amada’s dedicated sales, applications and service teams are eager and available to explain and demonstrate the full Amada solution at your request and at your leisure.

For more information, please contact Amada – Tel: 011 453-5459.