US Manufacturing Technology Orders (USMTO) continued to expand in July, up 23% from July 2016 order levels.

The July rate of increase is a notable acceleration in growth relative to the 10% increase in June orders posted over the previous year.

The nearly three-year decline in the U.S. manufacturing technology market turned the corner last March with a string of year-overyear improvements in order levels. IMTS 2016 rekindled the market last fall but it was not until March that year-over-year numbers began to consistently show a positive, accelerating trend upwards. At the current expansion rates, manufacturing technology orders are likely to outpace the growth rates analysts forecasted at last October’s Global Forecasting and Marketing Conference hosted by AMT.

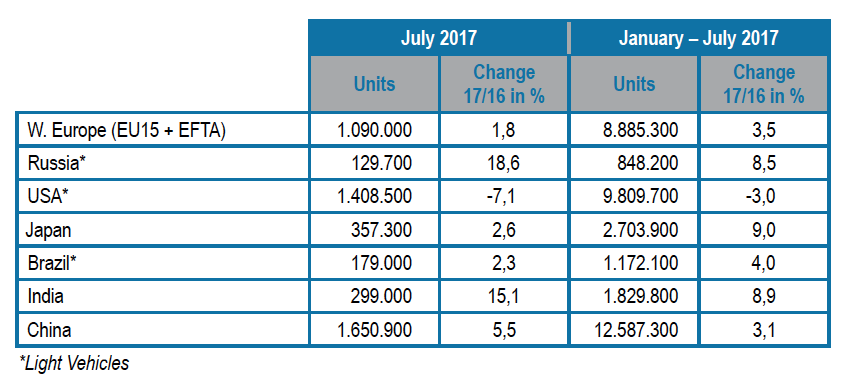

“It is encouraging to see the U.S. manufacturing markets and economy improving, especially when the European and Asian markets are not doing as well,” said Doug Woods. “AMT is excited about the prospects for 2017 and the possibilities in 2018, particularly if Washington takes steps to address tax reform and infrastructure spending.”

Orders posted in July are typically down 15% from the previous month. This year, orders followed that historical summer trend coming in at $320 million, off 19% from June orders of $397 million. “AMT members noted the marked difference in the start of this summer season,” said Pat McGibbon, AMT Vice President of Strategic Analytics. “Usually quotations and leads start to slow in the summer but that has not been the case in 2017.”

Several large projects converted mature quotations into major orders with bundled addons such as special tooling and automation. The contract machine shop sector, where companies typically buy one or two machines at a time, was one of the stronger markets in July, representing 41 percent of all the units ordered in July and 32 percent of the total July dollar value. The big surprise was a jump in defense orders from less than one percent of total orders to 4 percent in July – more than a 10-fold increase. Medical equipment and agricultural equipment sectors were up 10 percent and seven percent respectively.

The southeast region registered one the largest month-to-month declines in the past three years falling 34 percent relative to June and down 10 percent relative to July 2016. Almost the entire decline can be attributed to a dramatic drop in aerospace activity in the region. The northeast region posted the only regional increase over June figures of the six USMTO regions.