At this time, the accumulative effects of the slow-down of economic growth throughout the industrialized world and the decision by OPEC (Organization of the Petroleum Exporting Countries) at the end of 2014, not to reduce production to protect prices, were further intensified by the remarkable growth of oil production and slowing global demand. This perfect storm inevitably led to a major drop of crude oil price.

The effects on Oil & Gas producers have been dramatic – many previously embarked upon projects that began to make little or no economic sense. To help maintain their profitability or to assist in curtailing their losses, throughout this slowdown, countless companies reduced their expenditure. Many major projects were cancelled or postponed, proposed mergers and acquisitions in the oil & gas industry collapsed, as sellers and buyers were unable to settle on a fundamental agreement.

As a consequence of reduced activity in this important sector, global cutting tool manufacturers experienced a significant drop in business. In keeping with company’s reduced revenues, buyers were instructed to utilize existing inventories and to purchase cutting tools only when necessary, without keeping back-up stock.

Despite the global recession in the oil & gas market, there remained several important sectors that continued to run at full capacity. To aid the efficiency of these busy consumables sectors, cutting tool producers have been, and continue to be, approached with requests for help in reducing machined part costs, to further optimize manufacturing processes and to reduce cycle times. These demands have been satisfied by the launch of a new generation of advanced cutting tools.

These tools may appear more expensive, but importantly they deliver significant savings. Although cutting tools represent only 2-4% of total production costs, they have a massive effect on the overall efficiency of a process. The use of today’s minimally more expensive, innovative tools that deliver longer life, ensure faster cycle times and guarantee the continued quality of machined parts, makes undoubted economic sense.

The application of increased cutting speeds, in addition to the use of custom solutions (combination tools) that enable multiple steps to be combined into one, result in significantly reduced cycle times. The shares of machine, labor and administrative costs are decreased, delivering a total cost saving as well as the benefit of improved lead times. The result – added capacity and improved productivity!

ISCAR offers a range of innovative tooling solutions that are designed to simplify production, reduce costs and maximize productivity. Solutions with leading SUMOTEC Grade products provide improved tool life and enhanced reliability across a range of different materials. In addition to a comprehensive collection of cutting tools, ISCAR also provides superior technical support to all users.

Machining Solutions for Oil Country Tubular Goods

Tubing, Casing, Coupling, Line Pipes, Drill Pipes and Rotary Drill Bits

The aggressive conditions encountered in the oil & gas industries necessitate the use of the most appropriate high-quality materials – as a result these challenging materials require the use of the best available cutting tools.

Innovative system solutions by ISCAR include tools for pipe end machining seamlessly hot-rolled or welded steel pipes, for turning, peeling the cone, seal seat machining and thread connections.

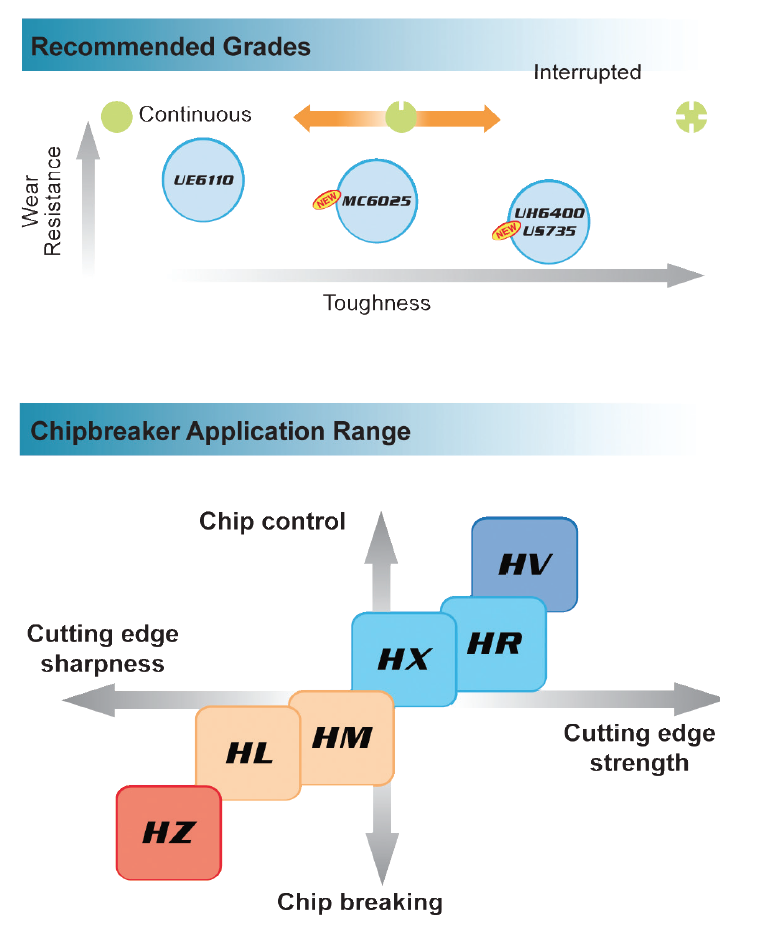

The SUMOTEC grade technology offers a new level of toughness and wear resistance for a wide range of applications and greater performance.

Parting Tubes and Rings

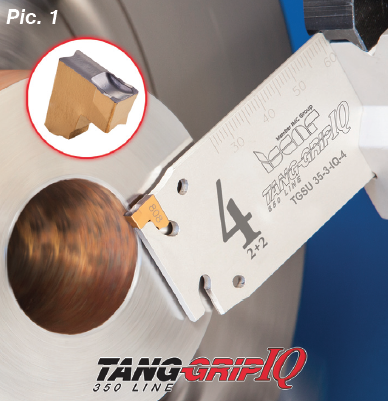

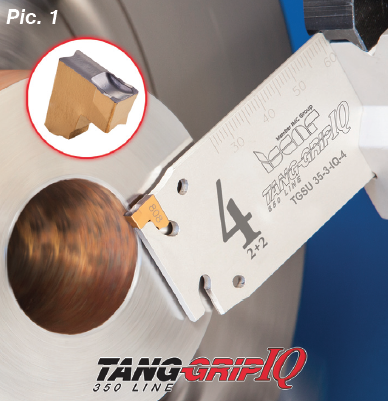

Tailor-made tooling combined with the revolutionary TANG-GRIP system, an extremely rigid clamping arrangement that ensures the highest levels of stability along with excellent chip control in most of materials, enables machining at high feed rates and provides excellent straightness and surface finish characteristics.

Tailor-made tooling combined with the revolutionary TANG-GRIP system, an extremely rigid clamping arrangement that ensures the highest levels of stability along with excellent chip control in most of materials, enables machining at high feed rates and provides excellent straightness and surface finish characteristics.

Included is a wide range of engineered holders and blades for parting tubes. (Pic. 1)

Turning and Threading

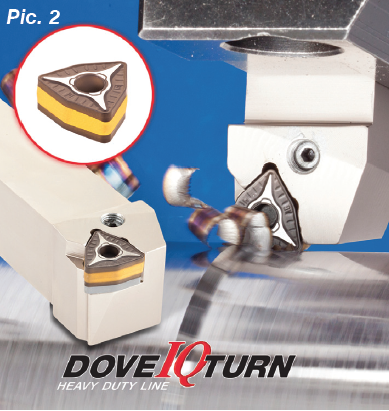

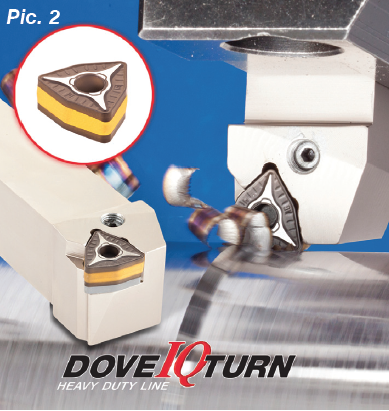

External and internal rough turning operations require a high quality surface and consistent results. High feed turning with DOVEIQ TURN and HELITURN TG turning inserts is a heavy duty ISCAR range that is ideal for rough turning operations and provides the benefits of a high depth of cut and high feed rates. (Pic. 2)

External and internal rough turning operations require a high quality surface and consistent results. High feed turning with DOVEIQ TURN and HELITURN TG turning inserts is a heavy duty ISCAR range that is ideal for rough turning operations and provides the benefits of a high depth of cut and high feed rates. (Pic. 2)

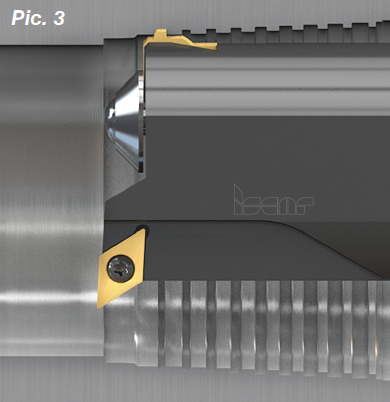

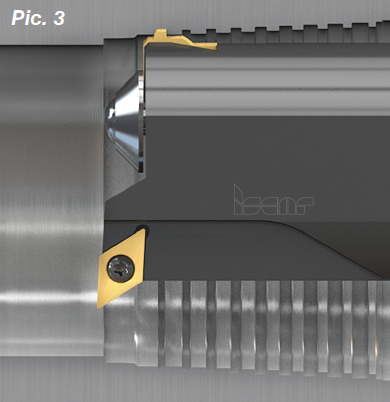

Multifunction tools for turning and threading operations are accurate indexing tools for a wide range of tubing and casing applications, and thus reduce cycle time and increase productivity. This product range provides tool solutions for high-performance thread cutting machines for API and premium threaded tubing and casing connections.

Multifunction tools for turning and threading operations are accurate indexing tools for a wide range of tubing and casing applications, and thus reduce cycle time and increase productivity. This product range provides tool solutions for high-performance thread cutting machines for API and premium threaded tubing and casing connections.

- Wide solution for API and premium threading

- High precision engineered tooling

- Optimized grade and geometry range for different materials (Pic. 3)

Multi-Tooth Threading Inserts and Chasers

Multi-tooth inserts are specially designed for high-volume production. Less passes are needed to cut the required thread and the cycle time is substantially decreased. ISCAR offers a wide range of threading inserts and chasers for the oil & gas industry, dedicated for the most common API standard threads and premium profiles.

External and Internal Skiving of Welded Seam

ISCAR’s scarfing solutions consist of both external and internal tools, in addition to the comprehensive range of indexable scarfing inserts for finishing operations of the welded joint.

Rock Drill Bits

Drill bits are cutting tools used to remove material through a cutting action provided by cones which have either steel teeth or tungsten carbide bit inserts.

The SUMOCHAM Chamdrill Line comprises a revolutionary clamping system that delivers improvements in productivity, while enabling more insert indexes. ISCAR offers tailor-made inserts with the appropriate point angle, corner radius and accuracy.

Machining Solutions for Wellheads, Valves and Frac Pumps

Wellhead and Subsea Equipment

Complex and highly engineered materials have become a standard demand for wellhead and subsea components.

Valves, Pumps and Connectors

Valves, pumps and connectors are fundamental components in pressure control systems, operating under aggressive conditions on both surface and subsea operations. The high strength of stainless steels, duplex and super duplex alloys with their high mechanical strength, and other exotic materials have long been a focus for ISCAR.

In order to meet the current and foreseeable challenges, ISCAR offers a range of advanced tooling solutions, suitable for machining exotic materials that can withstand deep-water hostile environments. This new generation of tools is an essential solution for productivity improvement in today’s oil & gas industry.

Holemaking

ISCAR’s all-embracing holemaking range provides all of the tools and technology needed for oil & gas component manufacturing. In this area, the key is to achieve the correct balance between the cutting edge, grade and geometry and the material being machined. ISCAR offers a complete package of hole making solutions for various machining challenges with a wide range of drilling tools including solid carbide drills and indexable inserts that meet all of the demands of accuracy and performance.

The CHAMIQDRILL features a unique design, utilizing the flexibility of carbide for self-locking, eliminating the need for clamping accessories. The robust structure of the drill with its concave cutting edge design enables drilling at high feed rates, providing very accurate adherence to tolerance. (Pic. 4)

The CHAMIQDRILL features a unique design, utilizing the flexibility of carbide for self-locking, eliminating the need for clamping accessories. The robust structure of the drill with its concave cutting edge design enables drilling at high feed rates, providing very accurate adherence to tolerance. (Pic. 4)

The SUMOGUN is the only gundrill in the market with an indexable drilling head. It features two effective cutting edges, enabling the drilling of deep holes at much higher feed rates, when compared to most other gundrills.

For large diameter drilling applications, the COMBICHAM drilling system is the ideal solution to boost productivity and efficiency regarding oil & gas deep drilling applications.

Milling

Innovation has always been an essential part of ISCAR’s milling range. All areas of oil & gas component machining can benefit from our knowledge. Cutters for face milling, helical interpolation, slotting, shouldering, plunge milling, high speed machining and many more solutions are available, along with the advice needed for their successful application. (Pic. 5)

Innovation has always been an essential part of ISCAR’s milling range. All areas of oil & gas component machining can benefit from our knowledge. Cutters for face milling, helical interpolation, slotting, shouldering, plunge milling, high speed machining and many more solutions are available, along with the advice needed for their successful application. (Pic. 5)

Thread Milling

Solid thread milling cutters are available in addition to thread milling indexable inserts for different thread profiles, providing a flexible and capable approach for high-quality threaded holes. This approach enables the production of precision threads, eliminates the problem of broken taps, reduces cutting forces and delivers shorter cycle times and increases productivity.

Solid Carbide End Mills – CHATTERFREE

The most advanced machining technology is ISCAR’s all-in-one solid EFP carbide cutter with its high-tech design providing a great advantage when cavity milling. A winning combination of ISCAR’s three most innovative endmills – unique cutting edge geometry, high stability performance during cutting and the delivery of higher feed rates, even with long tooling overhang. These unique features enable high metal removal rates when machining pockets and cavities in high-temperature alloys. As a result, the cutter delivers a significant reduction in cycle time, increasing productivity.

Customized Tooling

ISCAR designed its extensive standard product range to cover all of the most common applications. In addition, ISCAR is able to use its extensive knowledge to develop and produce the best solutions for customers’ processes not covered by standard products.

The Oil and Gas market faces many challenges to overcome the present situation, and ISCAR believes that effective collaboration with cutting tool manufacturers play an important role in helping the industry meet these challenges.

In addition to the latest technologies, we can see an industry focused on searching for creative methods and efficient processes. As a leading cutting tools manufacturer, ISCAR’s approach is to work closely with customers and provide them with innovating solutions by thinking outside the box to address these requirements and take productivity to the next level.

For more information, contact Iscar South Africa – Tel: (011) 997-2700.

First we will dive into the true slant bed design. Unlike the flatbed flying wedge design – where the slant is achieved by the addition of a bolt-on wedge that is mounted on the cross slide – the true slant bed machine casting is manufactured with the slant built in. This not only offers more rigidity and thermal stability, but also proves to give the casting more overall mass, and means you have a much heavier machine with a smaller footprint. Typically the true slant bed design is offered in one of two slant angles, 30 degree and 45 degree, but there are also some 60 degree models available.

First we will dive into the true slant bed design. Unlike the flatbed flying wedge design – where the slant is achieved by the addition of a bolt-on wedge that is mounted on the cross slide – the true slant bed machine casting is manufactured with the slant built in. This not only offers more rigidity and thermal stability, but also proves to give the casting more overall mass, and means you have a much heavier machine with a smaller footprint. Typically the true slant bed design is offered in one of two slant angles, 30 degree and 45 degree, but there are also some 60 degree models available. There are many advantages to the true slant bed design, and it is probably the most common configuration in modern CNC lathes. One of the most well-known and obvious advantages to the true slant bed is better chip evacuation. As the chips are created during the machining process, they are immediately washed down toward the chip bed by gravity and the normal flow of the coolant. This keeps chips from accumulating on flat surfaces, which not only helps control the chips in high volume production applications, but can also aid in prolonging the overall life of a machine – by reducing undue wear on the ways and other moving parts.

There are many advantages to the true slant bed design, and it is probably the most common configuration in modern CNC lathes. One of the most well-known and obvious advantages to the true slant bed is better chip evacuation. As the chips are created during the machining process, they are immediately washed down toward the chip bed by gravity and the normal flow of the coolant. This keeps chips from accumulating on flat surfaces, which not only helps control the chips in high volume production applications, but can also aid in prolonging the overall life of a machine – by reducing undue wear on the ways and other moving parts. Another advantage to the true slant design is larger X-axis travels. Unlike the flatbed lathes where guide rail length is limited to the horizontal depth of the casting, the true slant bed design allows for longer X-axis rails. Just like in a square box, the straight sides of the box are one specific length, but the angular distance from one corner to the other is much longer. The same is true for the slant bed casting design which obviously means a larger part capacity in a smaller machine footprint. Although the flying wedge design, with the bolt-on slant, can also offer some increased X-axis travels over traditional flatbed machines, it can also magnify the lack of rigidity that is present in the bolt-on approach. You just cannot substitute for a sturdy casting design.

Another advantage to the true slant design is larger X-axis travels. Unlike the flatbed lathes where guide rail length is limited to the horizontal depth of the casting, the true slant bed design allows for longer X-axis rails. Just like in a square box, the straight sides of the box are one specific length, but the angular distance from one corner to the other is much longer. The same is true for the slant bed casting design which obviously means a larger part capacity in a smaller machine footprint. Although the flying wedge design, with the bolt-on slant, can also offer some increased X-axis travels over traditional flatbed machines, it can also magnify the lack of rigidity that is present in the bolt-on approach. You just cannot substitute for a sturdy casting design.

For stainless steels and Nickel based super alloys, the well-known US735 grade has been added to complement the existing grades. The extremely tough carbide substrate of US735 is coated with a specially formulated, thin but tough Ti compound. This compound has super high adhesion strength to ensure it protects the substrate during the extreme conditions faced when turning difficult-to-cut materials.

For stainless steels and Nickel based super alloys, the well-known US735 grade has been added to complement the existing grades. The extremely tough carbide substrate of US735 is coated with a specially formulated, thin but tough Ti compound. This compound has super high adhesion strength to ensure it protects the substrate during the extreme conditions faced when turning difficult-to-cut materials.

This high-level contact and co-operation has supported the development and launch of a wide range of high-quality ISCAR cutting tools that have boosted the global Aerospace manufacturing sector’s productivity and assisted in assuring product quality across many machining disciplines.

This high-level contact and co-operation has supported the development and launch of a wide range of high-quality ISCAR cutting tools that have boosted the global Aerospace manufacturing sector’s productivity and assisted in assuring product quality across many machining disciplines.

Tailor-made tooling combined with the revolutionary TANG-GRIP system, an extremely rigid clamping arrangement that ensures the highest levels of stability along with excellent chip control in most of materials, enables machining at high feed rates and provides excellent straightness and surface finish characteristics.

Tailor-made tooling combined with the revolutionary TANG-GRIP system, an extremely rigid clamping arrangement that ensures the highest levels of stability along with excellent chip control in most of materials, enables machining at high feed rates and provides excellent straightness and surface finish characteristics. External and internal rough turning operations require a high quality surface and consistent results. High feed turning with DOVEIQ TURN and HELITURN TG turning inserts is a heavy duty ISCAR range that is ideal for rough turning operations and provides the benefits of a high depth of cut and high feed rates. (Pic. 2)

External and internal rough turning operations require a high quality surface and consistent results. High feed turning with DOVEIQ TURN and HELITURN TG turning inserts is a heavy duty ISCAR range that is ideal for rough turning operations and provides the benefits of a high depth of cut and high feed rates. (Pic. 2) Multifunction tools for turning and threading operations are accurate indexing tools for a wide range of tubing and casing applications, and thus reduce cycle time and increase productivity. This product range provides tool solutions for high-performance thread cutting machines for API and premium threaded tubing and casing connections.

Multifunction tools for turning and threading operations are accurate indexing tools for a wide range of tubing and casing applications, and thus reduce cycle time and increase productivity. This product range provides tool solutions for high-performance thread cutting machines for API and premium threaded tubing and casing connections. The CHAMIQDRILL features a unique design, utilizing the flexibility of carbide for self-locking, eliminating the need for clamping accessories. The robust structure of the drill with its concave cutting edge design enables drilling at high feed rates, providing very accurate adherence to tolerance. (Pic. 4)

The CHAMIQDRILL features a unique design, utilizing the flexibility of carbide for self-locking, eliminating the need for clamping accessories. The robust structure of the drill with its concave cutting edge design enables drilling at high feed rates, providing very accurate adherence to tolerance. (Pic. 4) Innovation has always been an essential part of ISCAR’s milling range. All areas of oil & gas component machining can benefit from our knowledge. Cutters for face milling, helical interpolation, slotting, shouldering, plunge milling, high speed machining and many more solutions are available, along with the advice needed for their successful application. (Pic. 5)

Innovation has always been an essential part of ISCAR’s milling range. All areas of oil & gas component machining can benefit from our knowledge. Cutters for face milling, helical interpolation, slotting, shouldering, plunge milling, high speed machining and many more solutions are available, along with the advice needed for their successful application. (Pic. 5)

The screw clamping type boring bar has a simple clamping structure, minimizes chip evacuation interference during internal machining and is stable plus durable during demanding operations.

The screw clamping type boring bar has a simple clamping structure, minimizes chip evacuation interference during internal machining and is stable plus durable during demanding operations. RhinoRush’s mini turning inserts have gained a huge following across many sectors within the manufacturing arena due to their reduced machining cost, increased output and competitiveness while keeping an eye on the environment.

RhinoRush’s mini turning inserts have gained a huge following across many sectors within the manufacturing arena due to their reduced machining cost, increased output and competitiveness while keeping an eye on the environment.