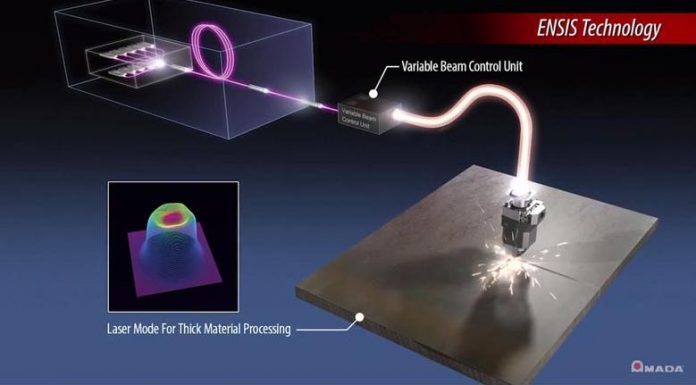

Amada ENSIS laser technology features unbelievable cutting capabilities, quality, efficiency and cost effectiveness. It has turned laser cutting into “laser processing”, thanks to the optimal beam manipulation capabilities that manipulate the mode shape according to material thickness being processed.

Simply put, a sharp mode is suitable to thin sheet processing, while a flatter mode is suitable to thick material processing. Standard machinery all work with a happy medium shaped mode which is set for both thin and thick cutting. Amada’s ENSIS is now capable of adjusting this mode shape automatically to the best suited shape for the material thickness being processed. This simply results in a far superior cut quality and higher processing speeds. An example of this is the capability of piercing a 25mm plate in one second on the 9kW ENSIS.

ENSIS technology has now also been incorporated into the RI (Rotary Index) – pipe cutting / flat sheet cutting laser – ENSIS 3015-AJ(RI). This 3kW laser offers the best of both worlds with the conventional flat sheet shuttle table system as well as the rotary pipe index system all in one machine. The award winning system has proven itself the world over with its CO2 power source, so the ENSIS fiber source can only capitalize on that reputation. Simple new features such as the probe feeler for pipe centering also make operation far more efficient, especially where raw materials are of inconsistent quality. ENSIS is available with a 3kW, 6kW and 9kW power option.

Additional features which are standard on the ENSIS all add to the efficiencies, such as the free roller bearing table to allow easy sheet positioning on the cutting table, Oil shot to prevent spatter build up, WACS (Water Assisted Cutting System) to reduce the thermal effect of cutting, automatic nozzle cleaning – ensuring consistent cutting head capacitance for non-contact processing, X Axis conveyor, and the Amada AMNC 3i control which shows “Real time’ part drawings as well as many other standard features.

ENSIS systems are very forgiving when processing with air as an assist gas. Again, reducing gas costs considerably due to the reduction in oxygen and nitrogen consumption.

Additional streamlined processing options available from Amada are automation options which are all fully retro-fitable to the equipment. Sheet manipulators (MPL) or a tower system (ASF) allow for material storage and the automatic loading/unloading of sheets or cut parts from the machinery. This results in a further saving of labour and consistent work flow, as the systems can run un-manned. Job scheduling ensures that the correct jobs and quantities are processed in order of preference and a full history is held for future reference if required. The advantage is now that small batch runs are possible from various lots of materials. Automatic nozzle changing further enhances set up or change over speeds.

For more information, please contact Amada – Tel: 011 453-5459.