Day 2 of the Manufacturing Indaba in Ekurhuleni culminated in delegates sitting on the edge of their seats to hear the banter and camaraderie that flowed between various CEOs and governmental representatives at the final afternoon of the two day event.

With a well-subscribed programme, a collaborative approach between government and the private sector was emphasized by many panellists from various manufacturing interest groups.

The theme for the conference was manufacturing the future and what that future will look like, both in the globalized and South African context. The manufacturing sector is the powerhouse behind many top performing global economies.

Government is pulling out all stops to encourage and stimulate growth in manufacturing in the face of tough headwinds anticipated in 2016 and the third annual Manufacturing Indaba was once again the platform for the public and private sector to find collaborative solutions to boosting South Africa’s manufacturing sectors.

Gauteng Premier David Makhura, who gave the closing keynote address after sitting through some of the panel discussions including The Mining Clusters, Localization in Manufacturing and Key Enabling Technologies, spoke about the importance of attending the annual Manufacturing Indaba to ‘keep us on our toes so we don’t miss the train and do things that are late, and lose time and money’.

“I regard this Manufacturing Indaba as a laboratory helping us to re-industrialize our province,” said the Premier. “It is significant that we are having this Indaba in Ekurhuleni because this is our manufacturing hub. This Indaba is a laboratory where we can reflect on and explore strategies to boost and revive this sector,” said Makhura.

The conference enjoyed high profile attendance from both government and the private sector with the Minister of Trade & Industry, Dr Rob Davies and the MMC of the City of Ekurhuleni, Cllr Thumbu Mahlangu hosting a press conference in conjunction with the private sector’s Bruce Strong from Mpact and Manufacturing Circle. Included in deliberations were CEOs of big corporations, cutting edge manufacturers and small business innovators who brainstormed the Fourth Industrial Revolution or Industry 4.0 and what that will look like in South Africa.

“Reindustrialization needs to be placed at the centre of economic policy today. If you’re not converted into a manufacturing activist yet, I hope you will be by the end of today,” said Stavros Nicolaou, Senior Executive of Strategic Trade at Aspen, who moderated sessions yesterday. “Think TMR when you go out of here – Transformation, Modernization and Reindustrialization.”

Despite tough economic times and global volatility, there were good news stories that were shared – South Africa’s thriving automotive sector, the reviving of the country’s textile sectors, the dti’s Black Industrialist Programme and Ekurhuleni’s Aerotropolis vision which sees the City leveraging its location, the presence of OR Tambo International Airport, and its existing industrial base to support rapid industrial growth and redevelopment of its communities.

“Reindustrialization is complicated and there aren’t quick wins. The Black Industrialists Incentive is to ensure that we give a leg up to emerging black industrialists and ensure people in South African local companies are being supported,” said Garth Strachan, Deputy Director General, Industrial Development Division with the Department of Trade and Industry (dti). “We’ve got to collaborate together to get it done. We’ve faced bigger battles as South Africans, we can do it together – let’s do it!” charged Strachan.

Three international manufacturing experts came to South Africa to address South Africa’s biggest manufacturing event.

Emeritus Professor of Economics at the London School of Oriental and African Studies (SOAS), Prof. John Sender spoke about important lessons from abroad and practical tips on implementing industrial policy in South Africa. He encouraged manufacturers to “reject the prevailing concern to catalogue preconditions for successful outcomes and to focus instead on possible paths, unexpected and unintended effects and inverted sequences. Aim for a few islands of excellence and pockets of effectiveness. Build on your strengths and shoot with a rifle, not a scattergun,” said Sender.

Professor Marco Taisch, the Scientific Chairman of World Manufacturing Forum 2016, the world’s leading global manufacturing event, shared with delegates how the digitization of manufacturing is changing the world we live in. “In future, companies will need to go from mass production to customization of mass production. They will have to go from product design to usage, like car sharing and bike sharing for increased value-adds. They will also have to go from real to digital where the physical and digital worlds are synced and matched, and from industrial automation to cognitive automation,” said Taisch.

Professor David Romero spoke on the development of Industry 4.0, sharing examples and lessons from Mexico’s booming manufacturing sector and tips from those nations that are at the forefront of the Fourth Industrial Revolution. Professor Romero is Professor-researcher at the National Graduate School of Science, Engineering and Technology (part of the Tecnologico de Monterrey’s Center for Innovation in Design and Technology in Mexico) and this was his second visit to the Manufacturing Indaba. Both international speakers were brought out by the Department of Science & Technology.

Hundreds of members of the public attended the free exhibition of local manufacturing products and technical workshops which were hosted by the National Cleaner Production Centre of South Africa.

The event and its corresponding exhibition has strategic partnerships with the Department of Trade & Industry (the dti), Department of Science & Technology (DST), host City of Ekurhuleni, Department of Public Enterprises, the Manufacturing Circle and the NCPC-SA.

South Africa is living in a digital era but the country’s transition and re-industrialization will look very different from that of other nations. We are at different levels of development and we have a unique background. What was clear from the 2016 Manufacturing Indaba discussions is that we need to develop our own solutions and make smart choices that encourage innovation, constant learning and skills development. And that is exactly what the Manufacturing Indaba is all about. The 2017 Manufacturing Indaba will take place on the 27th and 28th June 2017.

The fully automatic system is designed to ensure high quality part finish even on delicate bars. All machine settings for diameter changes are handled from a central location.

The fully automatic system is designed to ensure high quality part finish even on delicate bars. All machine settings for diameter changes are handled from a central location.

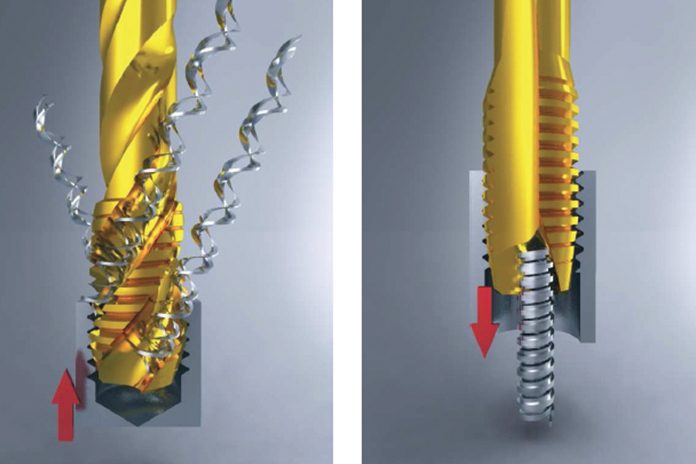

The material used in the new T-Tap line is offered in three different grades– uncoated, steam tempered or titanium nitride. No matter the coating, the T-Tap HSSE line enables higher productivity and economy on a wide range of materials. Its longer tool life is credited by its innovative cutting geometry and the option of either TiN or steam tempering.

The material used in the new T-Tap line is offered in three different grades– uncoated, steam tempered or titanium nitride. No matter the coating, the T-Tap HSSE line enables higher productivity and economy on a wide range of materials. Its longer tool life is credited by its innovative cutting geometry and the option of either TiN or steam tempering.