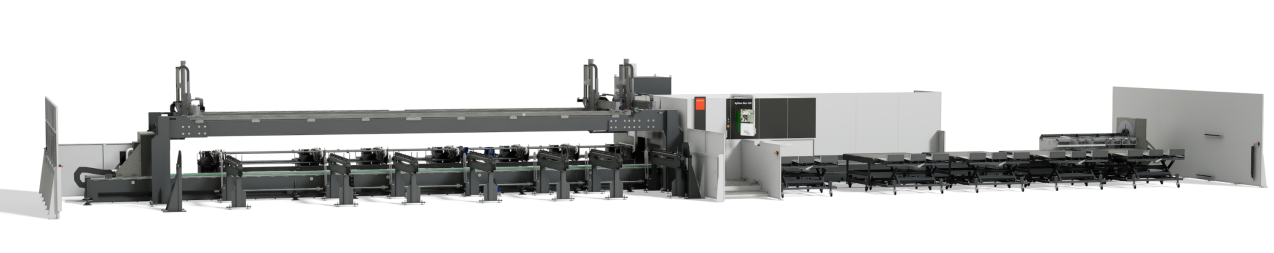

The new tube laser cutter ByTube Star 330

The new ByTube Star 330 is the most versatile tube laser on the market, with a loading length for tubes of up to 12.8 meters, a laser power of 6 or 10 kilowatts, and the capability to automatically process tubes and open sections within the entire range, from 19 to 305 mm, without set-up time.

The modular, large 3D fiber laser tube cutting machine ByTube Star 330 is the only one of its kind to automatically process tubes and open sections within the diameter range of 19 to 305 mm without set-up time. With minimal manual set-up, even processing up to 324 mm is possible.

With the ByTube Star 330, customers will experience a new level of efficiency. The tube laser offers a very high processing speed on the market for parts over 250 mm and 40 kg/m. Fully automatic feeding and sorting increases productivity and lowers the cost of labour significantly.

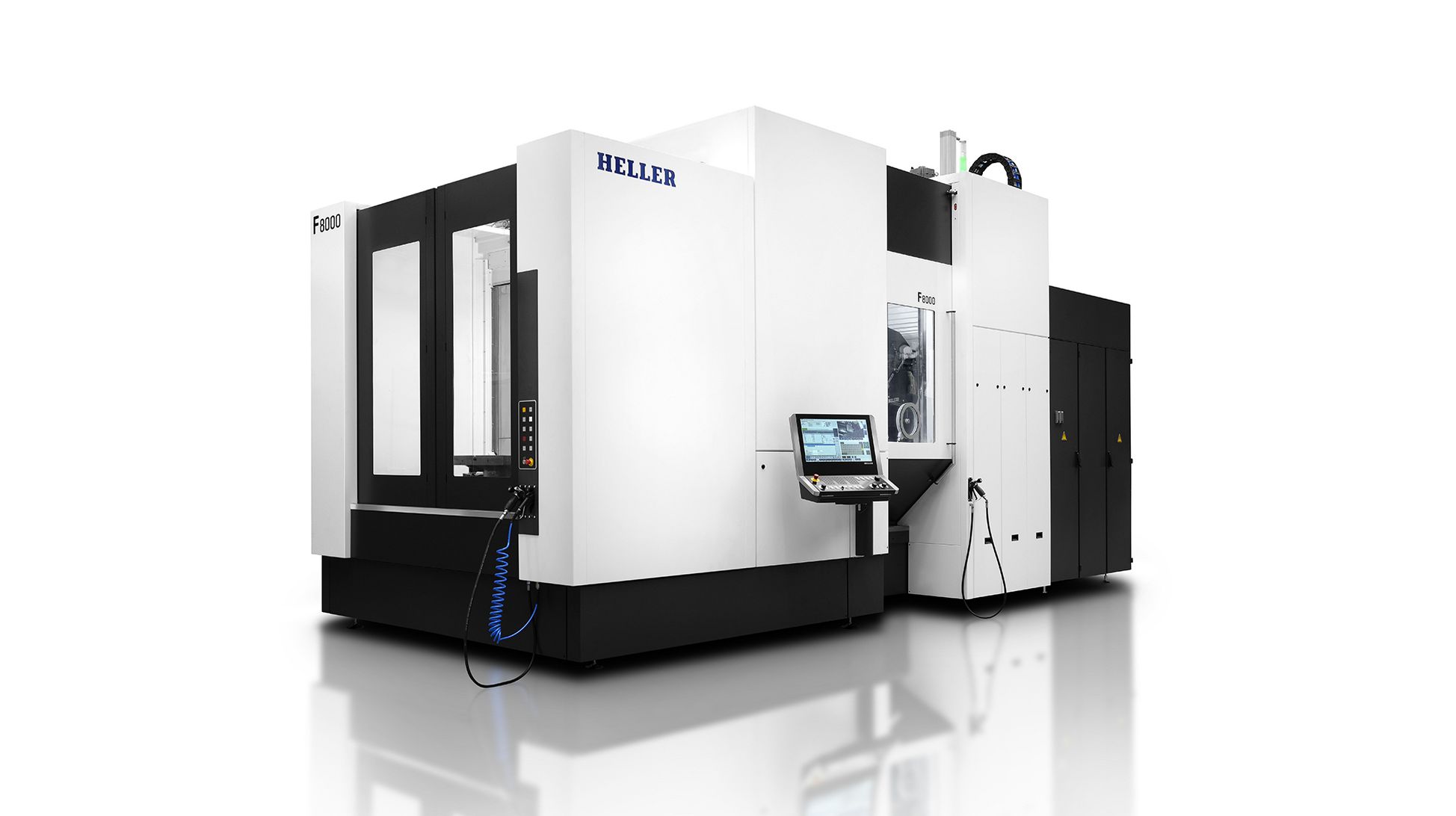

Enough power for everything

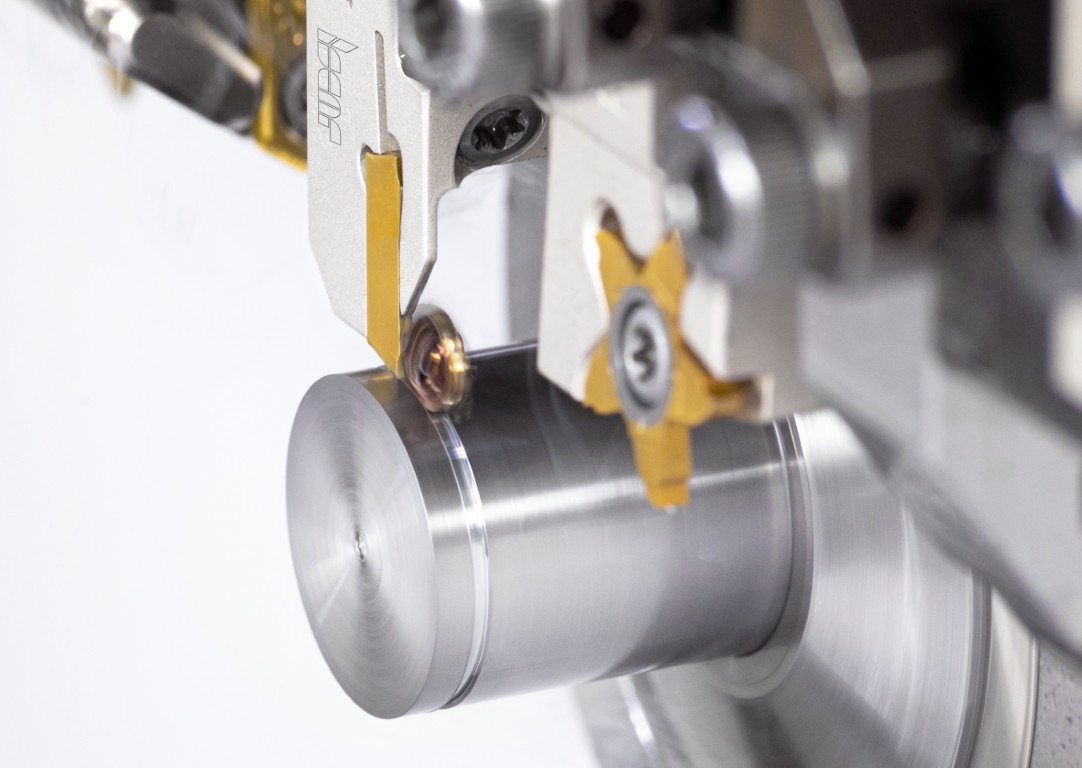

The laser source, available in a power choice of 6 kilowatts or 10 kilowatts, ensures sufficient power to cut even particularly large and thick tubes or profiles quickly and with the highest quality.

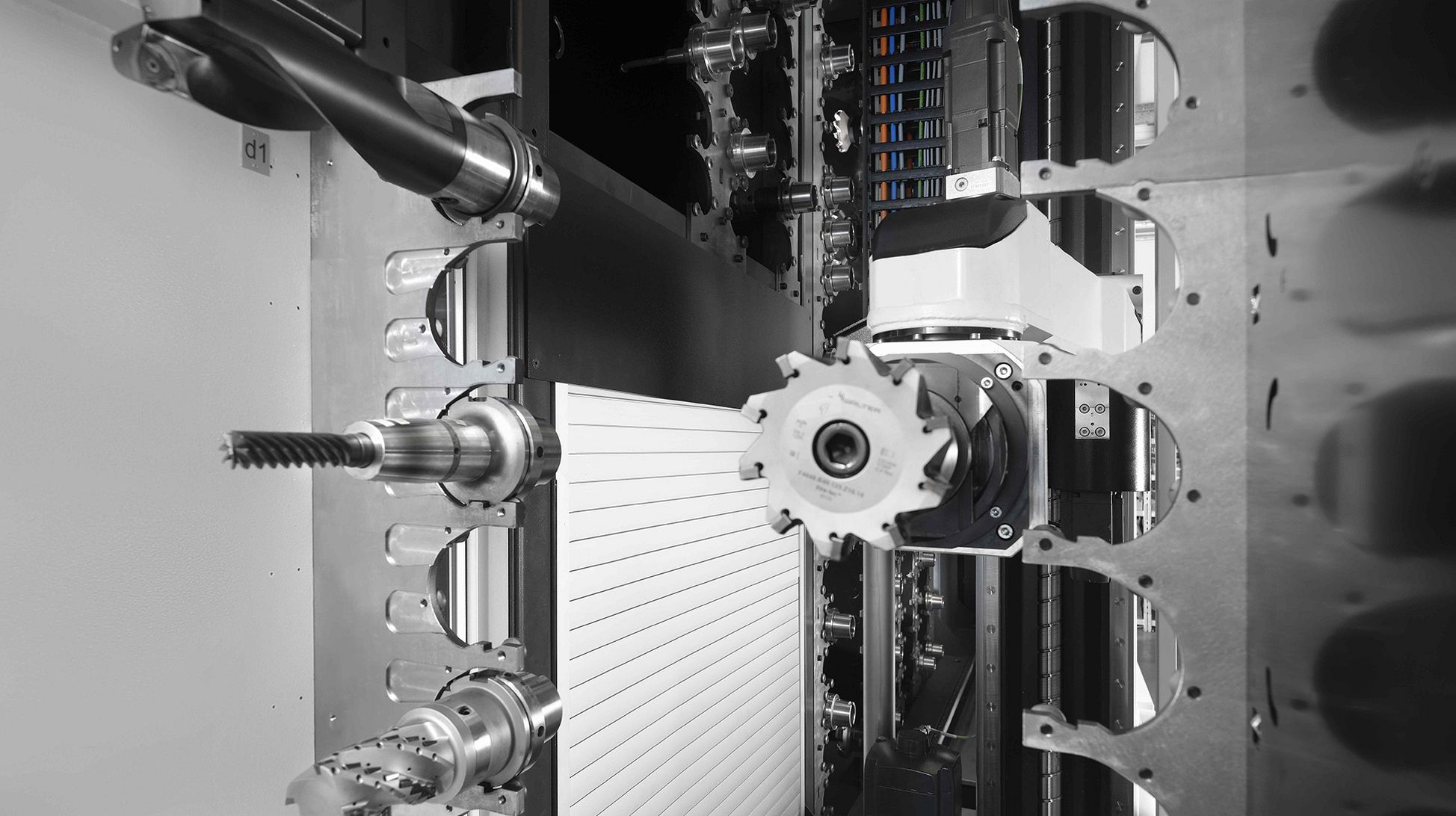

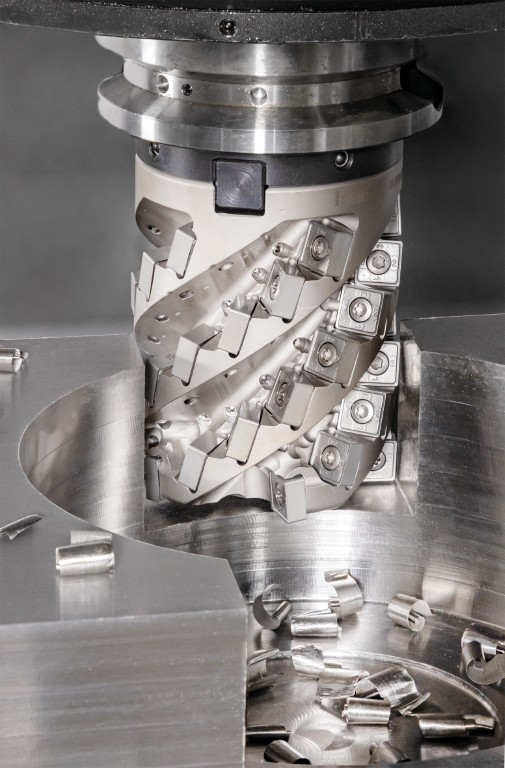

The ByTube Star 330 is the all-rounder that any production needs. It cuts all standard profiles (open profiles in boxes from 19.05 mm x 19.05 mm to 260 mm x 260 mm and open profiles C + L + H + I) and supports a broad range of diameters and different cutting processes.

The strengths of the ByTube Star 330

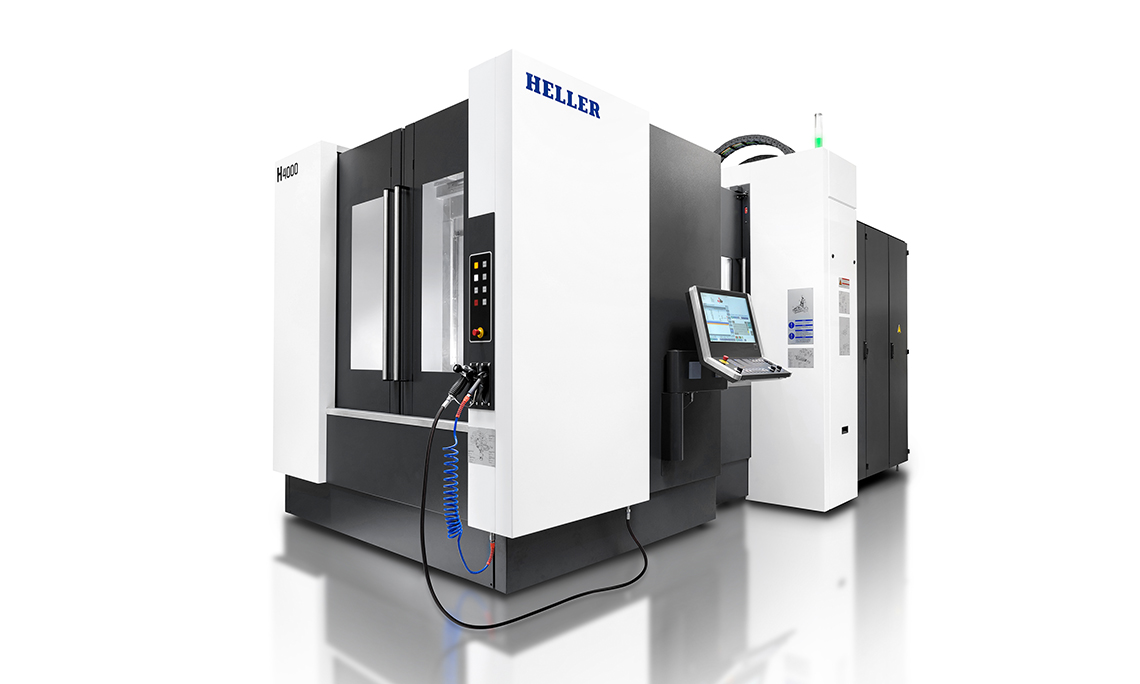

Versatility: The modular approach, with three different loading options that can be configured freely to accommodate a great number of possibilities, results in a custom-made solution for any floor space. Upgrades can be installed at any time.

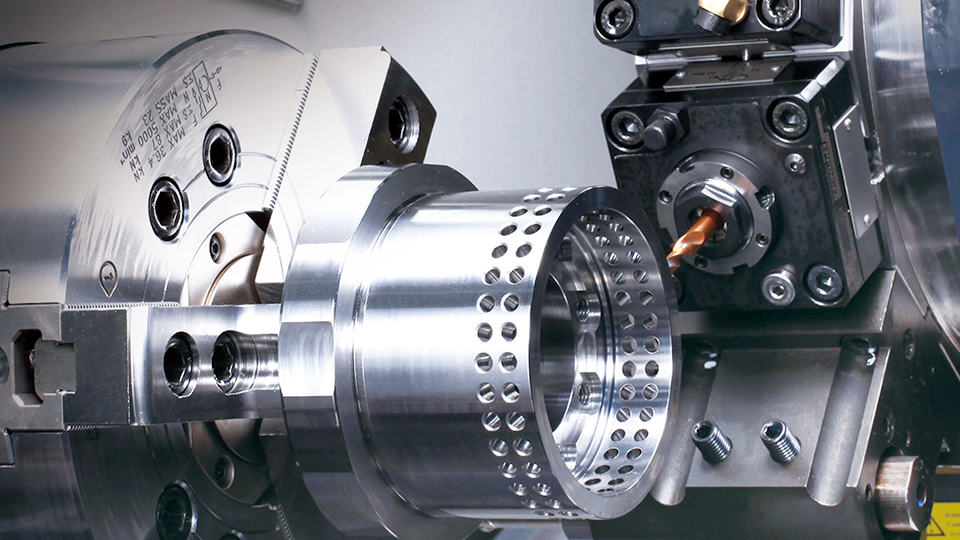

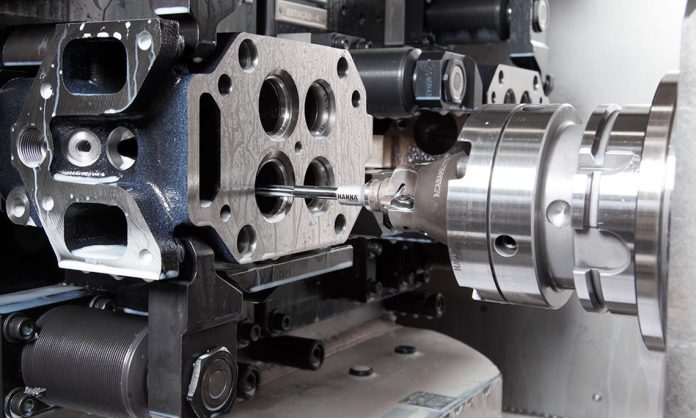

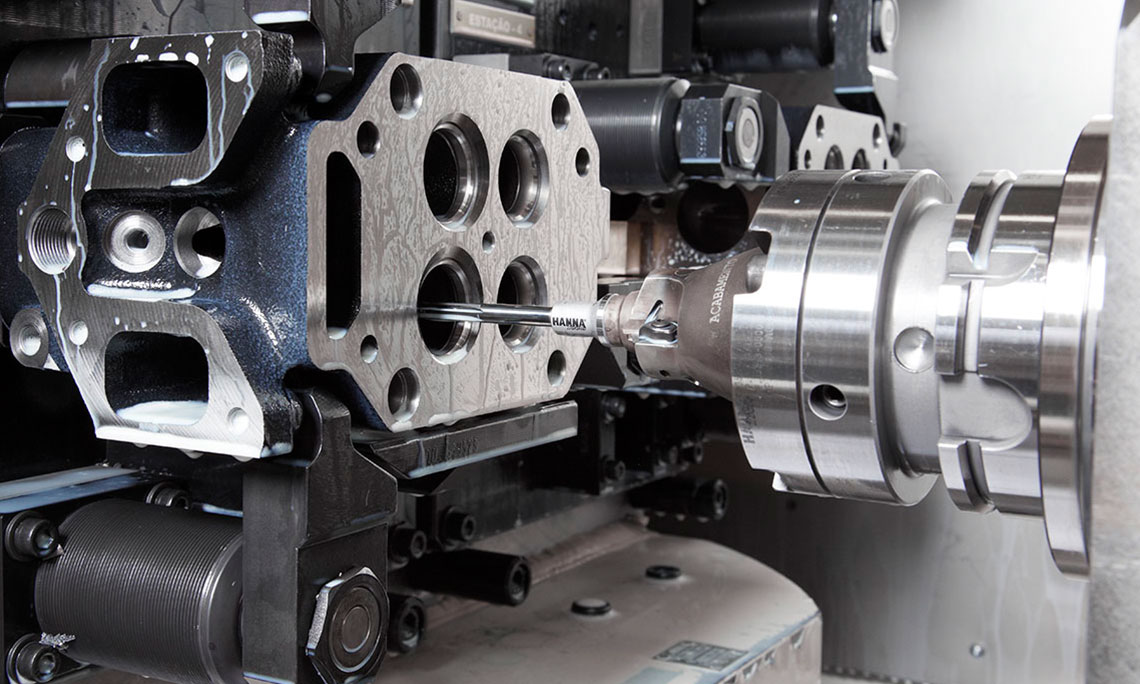

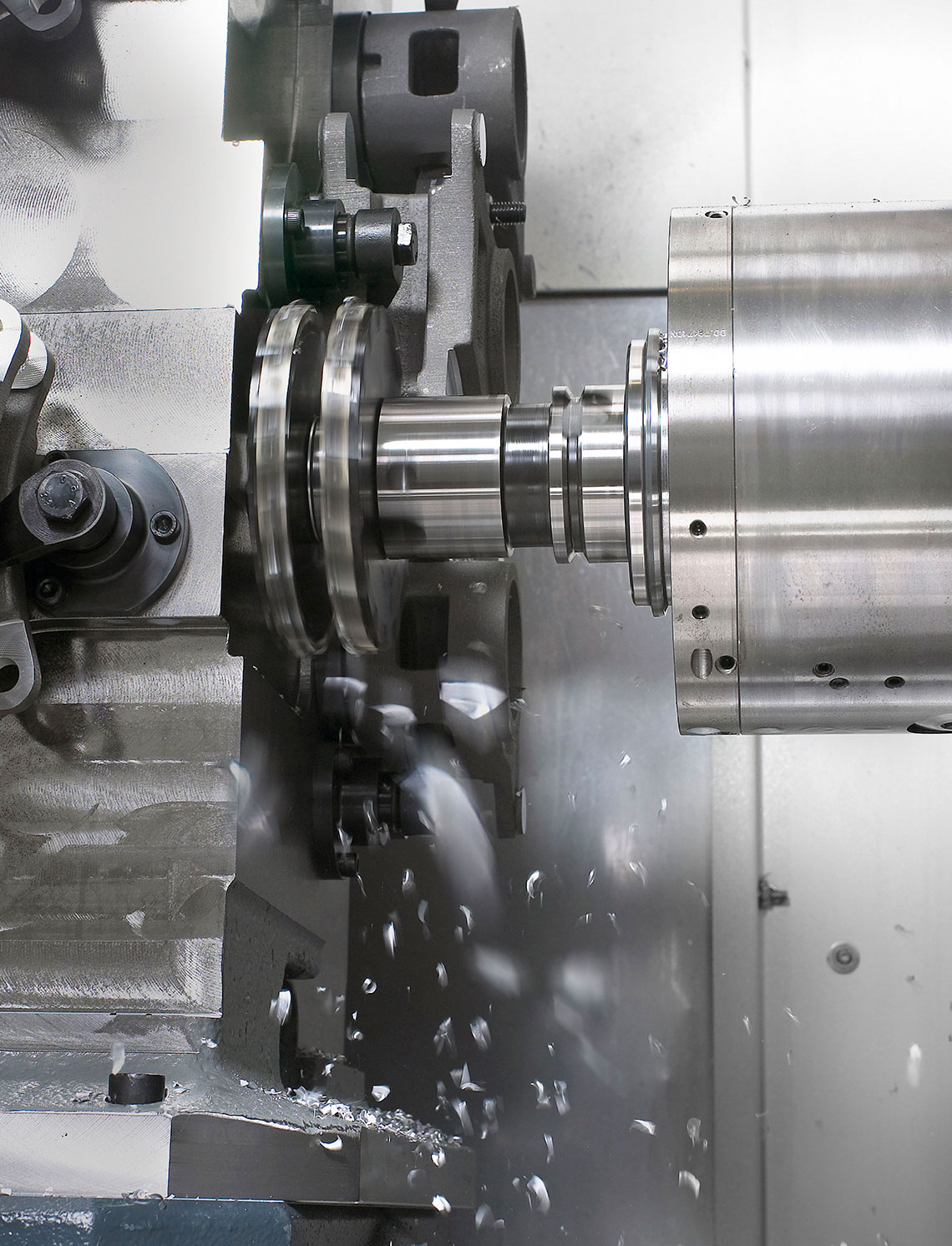

Automation: The integration of processes such as drilling, tapping, marking, and phase cutting without manual intervention saves on time and cost.

Powerful: With a laser power of 6 or 10 kW, the ByTube Star 330 masters even special requests, such as cutting thick tubes with bevel cuts, without compromising cutting quality.

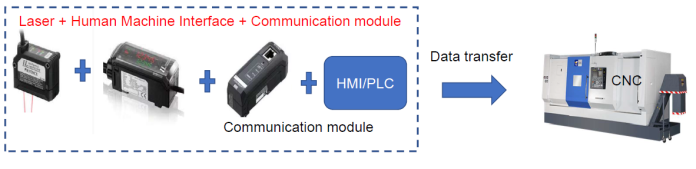

Expandability: Options such as Laserscan, Weld Search Camera, and Quick Cut guarantee the highest quality and safety in every work process.

Precision: The 3D cutting head and the Quick Cut option ensure the highest speed and quality, even with very small tubes.

User-friendliness: Due to the intuitive touch screen and tried-and-tested Bystronic HMI, operating the ByTube Star 330 is as easy as using a smartphone.

The ByTube Star 330 is the ideal solution for enterprises that want to optimize their production processes while increasing quality and efficiency.

Daniel Brenner, Global Head Marketing & Sales Tube says: “The new ByTube Star 330 sets new standards in tube laser cutting. Through unsurpassed flexibility and the combination of high power and a fully automatic set-up, our customers can significantly elevate their efficiency and quality. This is a great advancement for them. Thanks to the modular approach, the machine can be customized exactly according to any customer’s needs and offers all the technological highlights that provide the customer with the highest productivity, even when it comes to the most complicated components.”

For more information, please see www.bystronic.co.za or contact Bystronic on 010 410 0200.