ByTube Star 130 – THE ULTIMATE SOLUTION FOR TUBE PROCESSING

Sheet metal processors speed up their tube laser business with the new Bystronic ByTube Star 130, the high-end tube laser with the most functions. Precision, user-friendliness and a fully automatic setup with open profiles and ellipses lead to greater flexibility and quality in production.

With the ByTube Star 130 laser cutting system, sheet metal production operations enter into the tube processing business quickly and easily, thus gaining access to new customer groups.

Fully automatic setup

With the ByTube Star 130, sheet metal processors looking to expand their portfolios have the perfect solution for tube processing at their fingertips – fast, simple, efficient and with the most functions. The broad application scope for all metallic materials in sizes from 10 to 130 millimeters and raw material lengths of up to 8.5 meters opens up new possibilities.

The automated system reduces manual intervention to a minimum and thus makes getting started in tube processing particularly easy. At the same time, the machine covers an exceptionally broad range of needs: Since 85 percent of the market potential in the segment is in small tubes, the ByTube Star 130 is equipped for processing tubes with diameters of 10 to 130 millimeters. The machine has a loading capacity of up to 17 kilograms per meter. With the 2D cutting head, 90 percent of all customer requests are fulfilled as vertical cuts make up the largest market share.

Available in two power levels, 2 or 3 kilowatts, the fiber laser unit of the ByTube Star 130 scores points with excellent energy efficiency as well as consistent and even cutting quality.

Additional options enhance precision

Additional options can be configured individually and enable even more operating convenience and increased production quality, such as

- “Laserscan”: Real-time compensation for tube bending to improve cutting precision, i.e., high accuracy is guaranteed in all cutting conditions, even with low-quality material.

- “Quick Cut”: Greater speed for better performance thanks to an additional linear axis.

Automatic welding-seam recognition makes manually aligning raw material unnecessary. With Laserscan, the function independently recognizes and compensates for geometric deviations in tubes, thus guaranteeing accuracy in the cutting process regardless of raw material quality.

Left or right is not an issue

As the sole global supplier, Bystronic also provides the ByTube Star 130 laser cutting system in a design with a “mirrored” configuration upon request. This enables customers to select the optimal layout for their individual production flow. Although simple at first glance, the “mirroring” opens up benefits, while loading and unloading areas no longer get in the way. It reduces not only logistical effort, but also saves space and manpower. Thanks to faster throughput time, productivity can be significantly increased.

The ByTube Star 130 combines intelligent machine design and leading cutting technology. Its simple operation, broad application scope, and sophisticated options ensure that Bystronic customers always stay one step ahead of the field in increasingly tough competition.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.

SMART FACTORY SOLUTIONS – SCALABLE SOLUTIONS FOR SMART PRODUCTION

Bystronic offers its customers solutions that make them even more competitive, starting from stand-alone laser cutting systems or press brakes, to automation solutions, all the way to a complete Smart Factory “World Class Manufacturing” for every sheet metal processing enterprise.

From manual production, through automated production, all the way to the Smart Factory, Bystronic solutions help companies look to the future with success, thanks to optimized processes.

With three main categories of solutions, tailor-made for the individual needs of each client, Bystronic offers “World Class Manufacturing” solutions for all customer requirements.

With scalable system solutions, Bystronic combines machines, automation, and software to create a flexible network of intelligent components. Thanks to the centralized control of networked components, the Bystronic software suite offers full transparency – at any time and from anywhere.

How can sheet metal processing companies survive in a market with ever-intensifying competition? The magic words are process optimization, automation and flexibility. With the BySoft suite, Bystronic is launching the software needed to make these a reality. It combines machines, plans applications as well as production steps and optimizes process flows, whether for the automation of two machines or for a complete Smart Factory. Thanks to the open interface, components from third-party manufacturers can also be integrated.

In the age of Industry 4.0, the world is changing and with it the entire business environment. Volatile markets, smaller batch sizes, increasing product diversity and shorter output times are some of the challenges the sheet metal processing sector is currently facing. This requires new approaches from companies in this industry wanting to maintain their competitiveness.

Competitive production requires automated production processes. A high and consistent level of quality is decisive in today’s market. Here, lightly manned or unmanned production can make a crucial difference with its high degree of automation.

Centralized control of all components

With the BySoft suite, Bystronic has developed comprehensive software to support sheet metal processors in overcoming these challenges and ensuring a sustained competitive advantage.

This new, open software suite enables businesses to achieve the maximum with their production resources. Thanks to the centralized control of their virtual or physical components, they control and digitally monitor the entire processing flow. The Bystronic software suite offers full transparency with regard to machines and processes, be it in planning orders, controlling production, data processing during manufacturing, or office administration such as quoting, invoicing, etc. – at any time and from anywhere.

Seamless integration of third-party components

With scalable Bystronic system solutions, sheet metal processing companies can combine machines, automation, and software to create a flexible network of intelligent components, regardless of whether they use Bystronic machines or third-party systems.

With the BySoft suite, sheet metal processors can begin optimizing their production processes today with a view toward digital production. From top-of-the-range machines and automated production cells all the way to a fully integrated Smart Factory, Bystronic’s scalable solutions grow along with the requirements of customers.

With scalable system solutions, Bystronic combines machines, automation, and software to create flexible networks of intelligent components for original equipment manufacturers (OEMs) and contract manufacturers. With centralized control, Bystronic offers full transparency – at any time and from anywhere.

Sheet metal processing companies thus accelerate their production and workflows to stay one step ahead of their customers’ growing requirements.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.

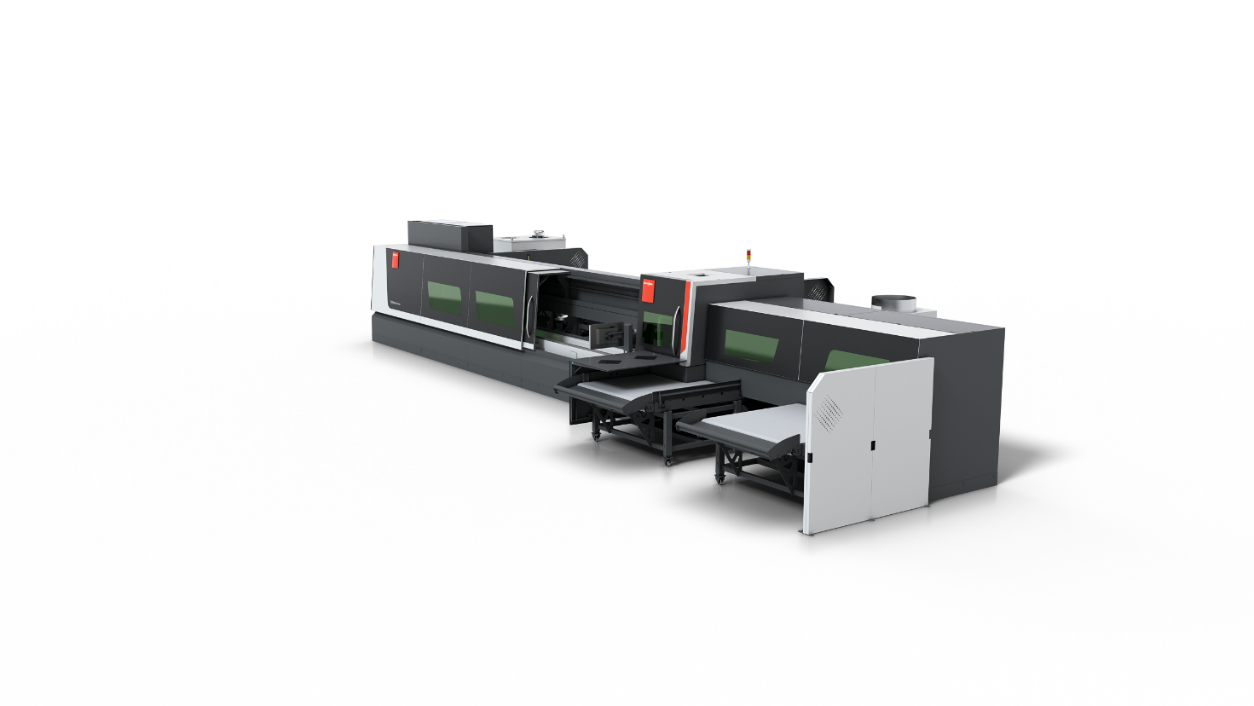

ByCut Smart 6225- HIGH PRODUCTIVITY AND PERFORMANCE AT AN AFFORDABLE PRICE

More sheet metal, more parts, more variety and a new design. The ByCut Smart 6225 further optimizes sheet utilization thanks to the 6225 cutting format. The new system features up to 10 kilowatts of laser power with the optional BeamShaper and all this at an advantageous price.

More sheet metal, more parts, more variety. Laser cutting systems for larger formats offer users the opportunity to distinguish themselves from the competition without excessive financial investment. That is why Bystronic is expanding its fiber laser product line ByCut Smart with the 6225 format in a new design. The machine can also be equipped with a choice of the Fiber 3000, 4000, 6000, 8000, or 10000 laser sources.

With the new large format, users can process sheet metal with lengths of up to 6.2 meters and widths of 2.5 meters on the ByCut Smart. This increases the productivity of the machine, because cut parts can be nested more efficiently on large-format sheet metal. At the same time, undesirable raw material waste is significantly reduced due to a high degree of material utilization. The BySoft CAM process software supports users in this process with intelligent nesting procedures.

Broad range of cutting applications

Furthermore, the new format increases the variety of cutting applications on the ByCut Smart. Along with various small parts, large parts can also be cut from large-format sheet metal as needed, without interrupting the machine during the laser cutting. This is another competitive advantage not offered by laser cutting systems in current standard formats.

Besides cutting applications with extra-large sheet metal, it is also possible to process sheet metal in smaller formats, lined up on the ByCut Smart’s long cutting table. In this process, users can prepare enough raw material for the fiber laser system to subsequently run in cutting mode for longer.

In addition to ByCut Smart 6225, Bystronic offers the fiber laser in 12020, 8020, 6520, 4020 and 3015 formats.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.