TaeguTec is introducing an exciting advanced line of performance-driven cutting tools specifically formulated for the Industry 4.0 revolution that not only guarantees incredible machining productivity by attaining quicker speeds and higher feed rates, but achieves longer tool life and unsurpassed consistency.

SFEED-TEC’s revolutionary tools are a premium high-speed and feed machining line that assures new winning results. In this new era of Industry 4.0, where time is of the essence, fast, accurate machining gives customers the competitive edge.

The powerful, new SFEED-TEC advanced technology – which stands for Sharp, Fast, Easy, Exact and Durable – has been applied to every family of tools within the TaeguTec umbrella, while at the same time TaeguTec has refreshed and upgraded its existing lines to exceed today’s challenges.

The global metalworking giant continuously works in close cooperation with its customers to push the boundaries of product design and innovation in order to develop highly effective and ingenious tool solutions that surpass today’s machining needs and propel customers’ manufacturing processes into the next level of production like never before.

Of the manufacturers already benefiting from the enriched SFEED-TEC family of cutting tools, the result has not only matched customers’ anticipation but has exceeded expectations by advancing their production output into unmatched exciting areas.

Furthermore, the new line of technologically advanced SFEED-TEC tools with its new cutting geometries and clamping mechanisms for stable, vibration free machining with higher repeatability, easily machines all alloys used in every industry. However, the true merit of this thrilling new line is its superb handling of difficult to cut materials quickly and efficiently.

The optimized new tools have sensational and creative cutting geometries and clamping mechanisms that firmly clench the tools in place; simply put, the result is stable, vibration free, rapid machining with an unmatched industrywide overall performance. SFEED-TEC’s powerful indexable inserts are equipped with sophisticated chip formers and leading-edge geometries that predict and facilitate soft cuts at high feed rates with ease.

Of the innovative and inspired product ranges that include strong holders, resilient inserts and sturdy cutters, five outstanding brands have been chosen as TaeguTec’s golden performers for their unmatched and exhilarating, Speed and Feed advance qualities that maximize equipment utilization and optimize performance.

TURN-SFEED takes the turn for higher speed and feed turning. This SFEED-TEC golden performer for multi-directional turning features a trigonal insert with 6 cutting edges for high speed and feed. The unique pocket structure and insert clamping mechanism withstands multidirectional forces to ensure continuous and consistent high feed turning. Coolant is efficiently blasted to the cutting edge from the top as well as the bottom of the tool.

This SFEED-TEC golden performer for multi-directional turning features a trigonal insert with 6 cutting edges for high speed and feed. The unique pocket structure and insert clamping mechanism withstands multidirectional forces to ensure continuous and consistent high feed turning. Coolant is efficiently blasted to the cutting edge from the top as well as the bottom of the tool.

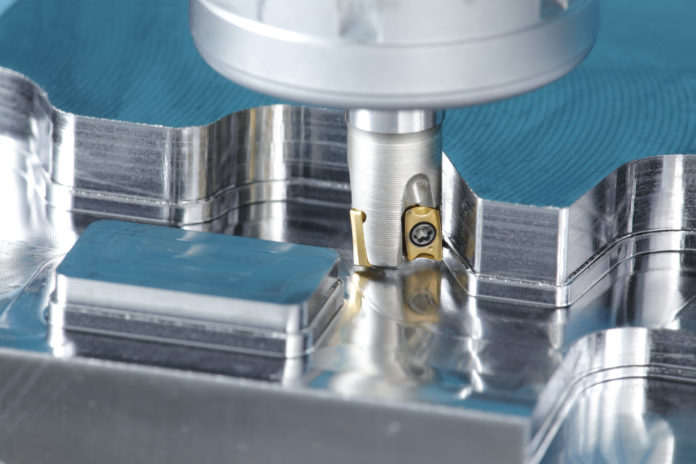

For parting and grooving, TaeguTec’s CUT-SFEED original design goes beyond the metalworking world’s imagination and expectations for single-ended inserts that perform parting and deep grooving applications. The new line resolves the challenges where others have failed by rectifying the issue of vibration, unstable tool life and frequent breakage stemming from bad chip evacuation.

The innovative and superlative golden CUT-SFEED line, and its new robust insert, is shaped to provide high stability. The unique clamping system enables machining at high-speeds and feeds for greater productivity. The tools are designed with pinpointed coolant accuracy for better edge life and efficient chip evacuation.

The innovative and superlative golden CUT-SFEED line, and its new robust insert, is shaped to provide high stability. The unique clamping system enables machining at high-speeds and feeds for greater productivity. The tools are designed with pinpointed coolant accuracy for better edge life and efficient chip evacuation.

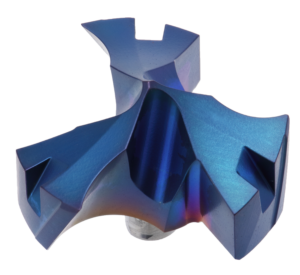

SFEED-TEC’s phenomenal DRILL-SFEED, with its innovative head changeable solid carbide heads, features 3 effective cutting edges and is the right solution to increase production by an industry leading 50 percent. The unique self-centering head geometry creates high balancing forces at the workpiece penetration point and promises reliable performance in high cutting conditions. This golden drilling line offers accurate hole sizes and premium surface finishing on steel and cast iron materials.

The intelligent design of the DRILL-SFEED’s head runout remains accurate in its position after replacement, assuring no setup time because of the fast head replacement operation and minimum machining downtime.  Moreover, the line’s advanced blue coating technology combined with its 3 effective cutting edges, as well as the highly efficient internal coolant system that enables for excellent chip evacuation, empowers this SFEED-TEC flagship to drill at high-speeds and feed rates.

Moreover, the line’s advanced blue coating technology combined with its 3 effective cutting edges, as well as the highly efficient internal coolant system that enables for excellent chip evacuation, empowers this SFEED-TEC flagship to drill at high-speeds and feed rates.

Milling solutions have been answered with two incredible golden offerings, MILL-SFEED and TANG-SFEED.

MILL-SFEED is a golden indexable line for 90-degree shoulder milling that is now smaller than ever.  The unique, advanced V-shaped insert has a strong and durable structure, for small diameter tools down to a 6 mm diameter. The V-shaped pocket possesses a durable structure that allows for highly stable insert positioning, which is vitally important in small diameter cutters.

The unique, advanced V-shaped insert has a strong and durable structure, for small diameter tools down to a 6 mm diameter. The V-shaped pocket possesses a durable structure that allows for highly stable insert positioning, which is vitally important in small diameter cutters.

Also, MILL-SFEED enables for the mounting of an increased number of inserts so that they could be used for various applications due to high ramp down and plunging capabilities. Additional inserts for high feed rates can be mounted on the same tool, which allows for 0.7 mm feed per tooth in shallow depths of cut. Overall, this milling genius combines high speeds and feeds for higher productivity.

Last but not least is the golden TANG-SFEED brand, a new revolutionary line for high-speed and feed milling. Moving tangentially with its new golden rigid inserts for 90 degrees shoulder milling, TANG-SFEED’s thick robust inserts are mounted on a strong tool body with a large core and can absorb very high cutting forces. The tool design produces exact 90-degrees shoulder operations, which avoids mismatch when machining next to walls. The insert design provides an exclusive option for ramp down. On the whole, TANG-SFEED enables machining under tough conditions with unsurpassed consistency for extraordinary speeds and feeds.

Being at the forefront of innovation, technology, design and creativity, TaeguTec’s technologically advanced, unique and premium Speed and Feed inspired tools help to accentuate the fourth industrial revolution into one that increases productivity while reducing cost – two factors that increase profitability and directly responds to the diverse needs of the metalworking world.

For more information please contact TaeguTec – Tel: 011 362-1500.

Visit TaeguTec