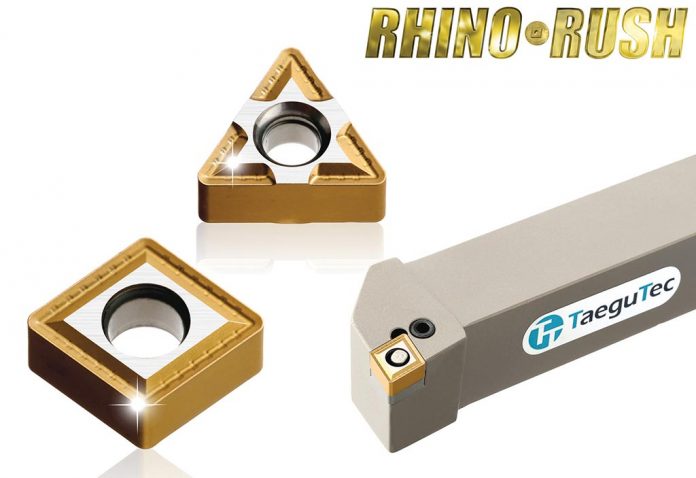

The RhinoRush MK chip breaker is ideal for medium applications while machining stainless steel and heat resistant materials.

The MK chip breaker is a more stable insert that offers long tool life because of its sharp edge design that minimizes built-up-edges during machining operations.

Case studies prove the effectiveness of the MK chip breaker with tool life being increased by over 300 percent.

For example, during the product testing phase of a workpiece made from SUS 304, the MK chip breaker coated with TaeguTec’s TT9080 grade witnessed an increase of tool life by 343 percent during continuous cutting conditions with speeds of 160 meters per minute and same cutting conditions.

During another continuous cutting test, on difficult-to-cut Inconel 718, tool life was increased by 159 percent with all cutting parameters the same.

The RhinoRush FS chip breaker is specifically designed for excellent chip control on steel finish turning with superior evacuation under low feed and low depth of cut applications, while the insert’s sharp cutting edge drastically reduces machining load resulting in minimal vibration during operations.

For more information contact TaeguTec – Tel: (011) 362 1500