With 30 percent enhanced precision, performance and efficiency DMG MORI has set new standards with the fourth duoBLOCK® generation.

The extensive cooling measures, together with the top rigidity of the fourth generation of the duoBLOCK® concept, are the basis for the very highest demands on precision and machining performance. Cooled guideways and drives plus the optional spindle growth sensor ensure minimum thermal-related displacement of just 12 μm. Numerous features of the basic structure also promote the high long-term accuracy of the DMU 160 P 4th generation duoBLOCK®. These include large linear guideways in all axes and standard double wipers as well as the re-designed ball screw principle in the X- and Y-axes. In addition, the geometry of the Y-axis has been improved by means of an optimized fixator position. Fixation of the standard Magnescale measuring system in the Y-axis on a carbon plate has optimized the measuring accuracy Cont. on page 16 thus resulting in a more exact positioning accuracy of the table.

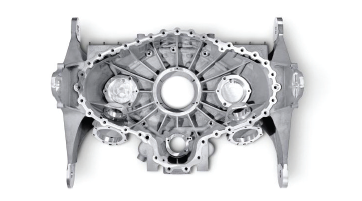

As the largest model in the series the DMU 160 P duoBLOCK® 4th generation has also been given a larger work area. This now measures 1,600 x 1,600 x 1,100mm. Table dimensions are Ø 1,600 x 1,250mm and the maximum workpiece weight has been increased to 4,500kg. Productive and dynamic 5-axis machining is effected with rapid traverses of up to 60m/min in all axes. The acceleration rates in the X, Y and Z-direction are 6 m/s², 4 m/s² and 7 m/s², respectively.

The modular concept of the DMU 160 P duoBLOCK® 4th generation offers an ideal solution for every application – starting with the innovative wheel magazine, which in its largest expansion stage can accommodate 453 tools (SK40/HSK63) and on to include the most extensive range of spindles to be found anywhere on the market. The offer here ranges from the powerMASTER® motor spindle with up to 1,000 Nm to the gear spindles with max. 1,800 Nm and on to include the speedMASTER® spindles with their impressive speeds of up to 30,000 rpm. The standard version of the DMU 160 P duoBLOCK® 4th generation comes equipped with a motor spindle that achieves a speed on 15,000 rpm and a torque of 200 Nm.

The 4th generation DMU 160 P duoBLOCK® appears completely revised in the joint design from DMG MORI, which embodies quality and value retention and offers functional added value in work ergonomics thanks to optimized accessibility. CELOS® is used for its control. This uniform appbased user interface with its unique multitouch screen is as simple to operate as a smartphone. As a result, users benefit from a 30 percent saving in setup time and 50 percent less effort for calculating technical values and searching for important information.

For more information, contact Retecon – Tel: (011) 976 8600.