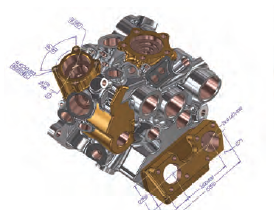

Mastercam is known for precision NC programming, but it also delivers a suite of shop-tested design tools aimed at getting parts on and off the machine as quickly as possible. Powerful modelling tools include not only 3D surfacing and solids, but hole-filling, direct editing without a solids history, geometry repair and much more.

Mastercam Design streamlines and simplifies modelling and editing geometry. It also supports advanced geometry creation, including solid modelling, hybrid machining, NURBS curves and surfaces, 2D and 3D associative dimensioning, surface extension, blending, trimming, splitting, variable filleting, solid modelling, and hybrid modelling to complete your jobs quicker and more efficiently.

New enhancements to Mastercam 2017 Design are:

Optimize: Repairs imported solids (whole bodies or individual faces) by improving the accuracy of edges and by identifying and optimizing blends, allowing other Model Prep functions to work better. Toolpaths on the repaired solid maintain associativity to faces.

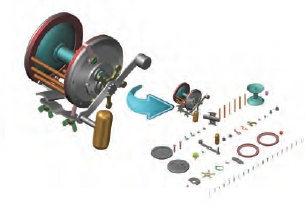

Solid Disassemble: A model prep function that takes a solid assembly and lays each body out in a single plane. It works on models with and without history, imported from other systems, or created from within Mastercam. The user interface has been improved to better support your machining practices, allowing you to place each solid body on its own level at the toolpath origin, saving you time and extra steps.

Preprocess Solid: The surface from solids function now includes a preprocess solid option that can help clean up errors in imported solids by assisting in the conversion of solid faces into surfaces. Mastercam makes a copy of the body, prepares it and then creates surfaces from this body. After the conversion, Mastercam deletes the preprocessed body, leaving the original intact.

Other Mastercam 2017 Design Improvements:

- The X, Y and Z options in the plane selection dialog box have been enhanced to increase functionality, accuracy and efficiency by eliminating extra steps and guess work.

- Repair small faces analyzes solid bodies (with no history) and reports if it finds small entities such as spikes, sliver faces, edge pinches, or gashes.

- Solid impression can speed up the creation of an electrode tool without having to create extra operations.

- Transform dynamic now supports AutoCursor snapping to horizontal, vertical and tangent positions when rotating geometry.

- You can now dynamically manipulate geometry with Mastercam’s new trio of single-axis arrow controls and so much more.

For more information, contact Mecad Systems – Tel: (012) 645-4300.