Equipped with a 73 kW high-power motor, an excellent machine structure and further enhanced spindle and axis ball screw stiffness, the ML-280 Series offers excellent cutting capability up to a maximum turning diameter ofø400 (Disc) and ø210 (Axis) and with a maximum turning length of 600mm.

The ML-46 is equipped with a high-speed hydraulic collet chuck to reduce production time needed for each part. This gives the machine a higher output rate compared to most standard lathes on the market.

The ML-46 is designed to fit every customer’s operational needs and controllers such as Fanuc, Mitsubishi plus other types of NC equipment can be supplied to meet any requirements.

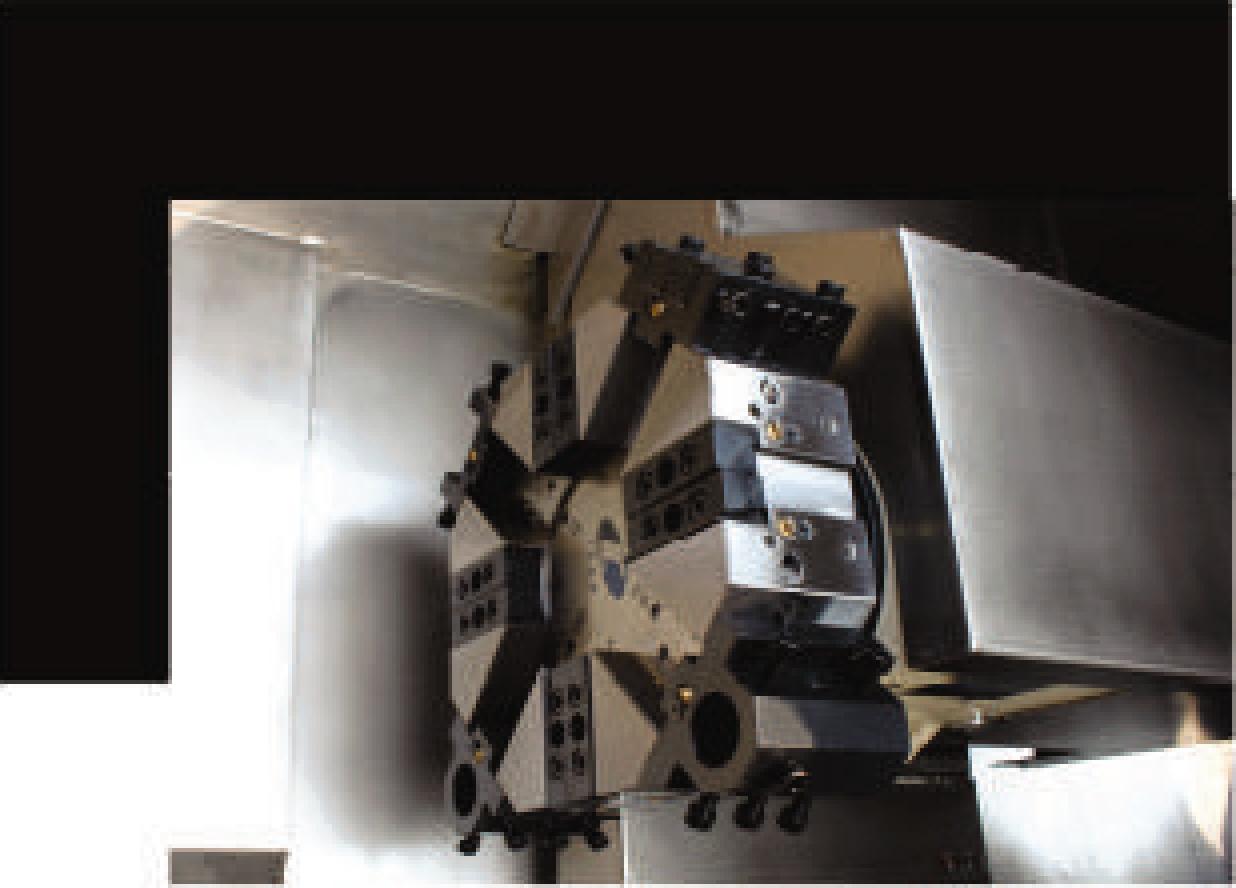

The 45° degree work bed provides this high speed lathe with a larger work area and the capability of installing more tools, while at the same time turning larger work pieces.

The fully enclosed casing design provides the machine operator with a clean and safe working environment.

The ML-Series’ excellent reliability is based on the adoption of a wider support structure, more stable bed, lower vibration and lower noise spindle. Add to this a servo-driven turret, a fully enclosed cover for preventing coolant leaks and chips from penetrating the machine while the operator is working on the work piece. Using a high quality C3 roller type linear guideway with NS K bearings ensures stability.

The CNC programmable tailstock with standard hydraulic tailstock enables the user to operate peripheral devices quickly and conveniently. This helps reduce the time it takes to setup each work piece manually, creating higher production profitability.

More and more customers are asking for solutions that can help increase production and reduce cost. The Maple ML-Series is the answer to both those requests. With customizable solutions for parts catchers, part feeders and robotic arms, the machine can operate automatically with very little stoppage time, while providing a higher output rate then other machines on the market.

For more information, contact 600 SA Machine Tools – Cell: 072 157 6003.