The SBX500 DoubleTurn M.C.Y is a high productivity turning center of a rigid design suitable for medium to large production of simple as well as complex geometrical shapes. Machine execution with Y-axis and live tools allows machining of complex shaped workpieces on a single machine which significantly reduces production time and increases workpiece accuracy. The machine seriously contributes to increased productivity while decreasing investment costs.

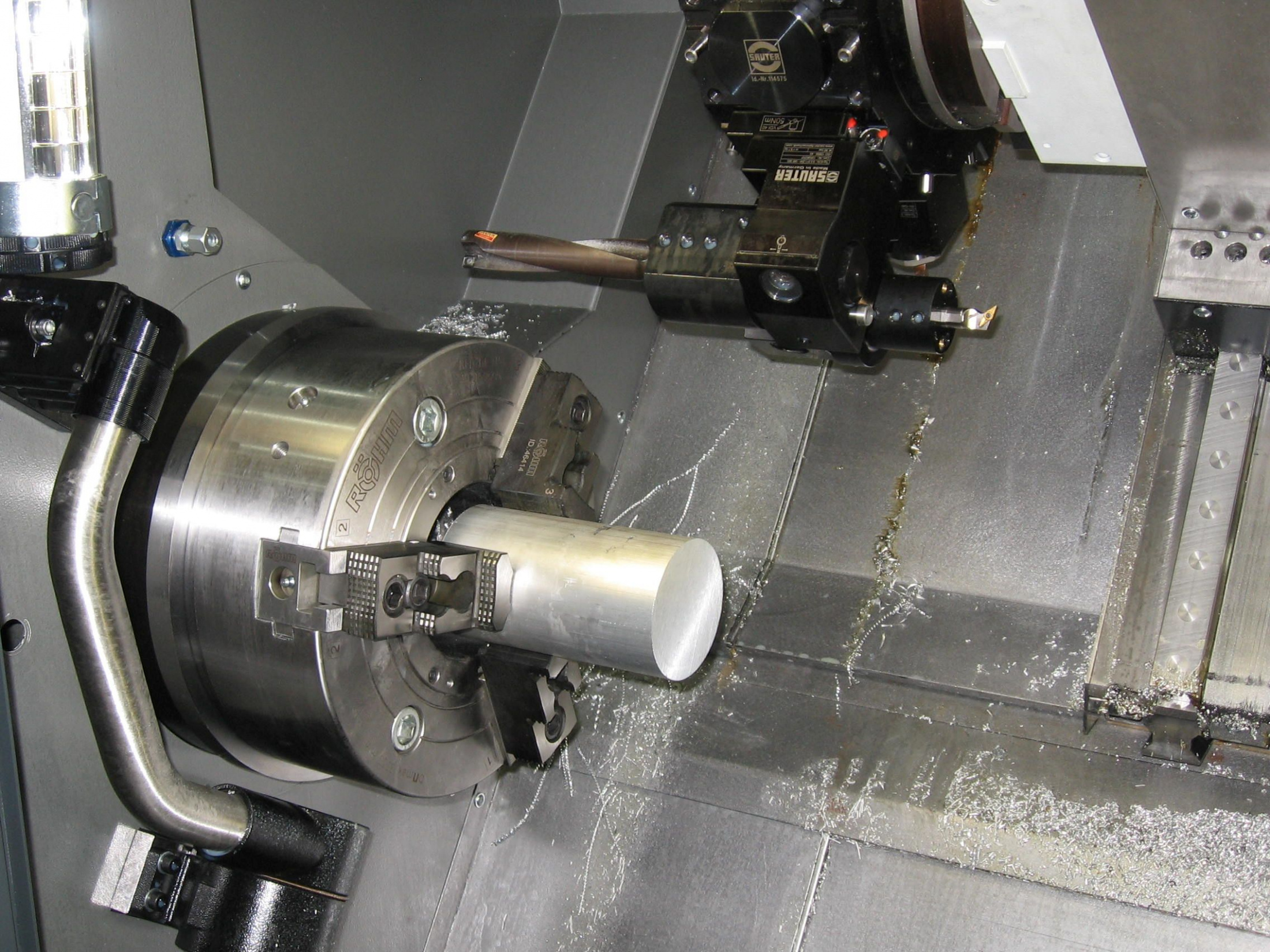

Notable features include a modular conception allowing configuring the machine for a wide range of technologies and materials, a counter spindle with passing hole clamping allowing complete machining, Y axis with saddle wedge contributing to increased stability of cutting process and a fast turret with 12 live tools size VDI 40.

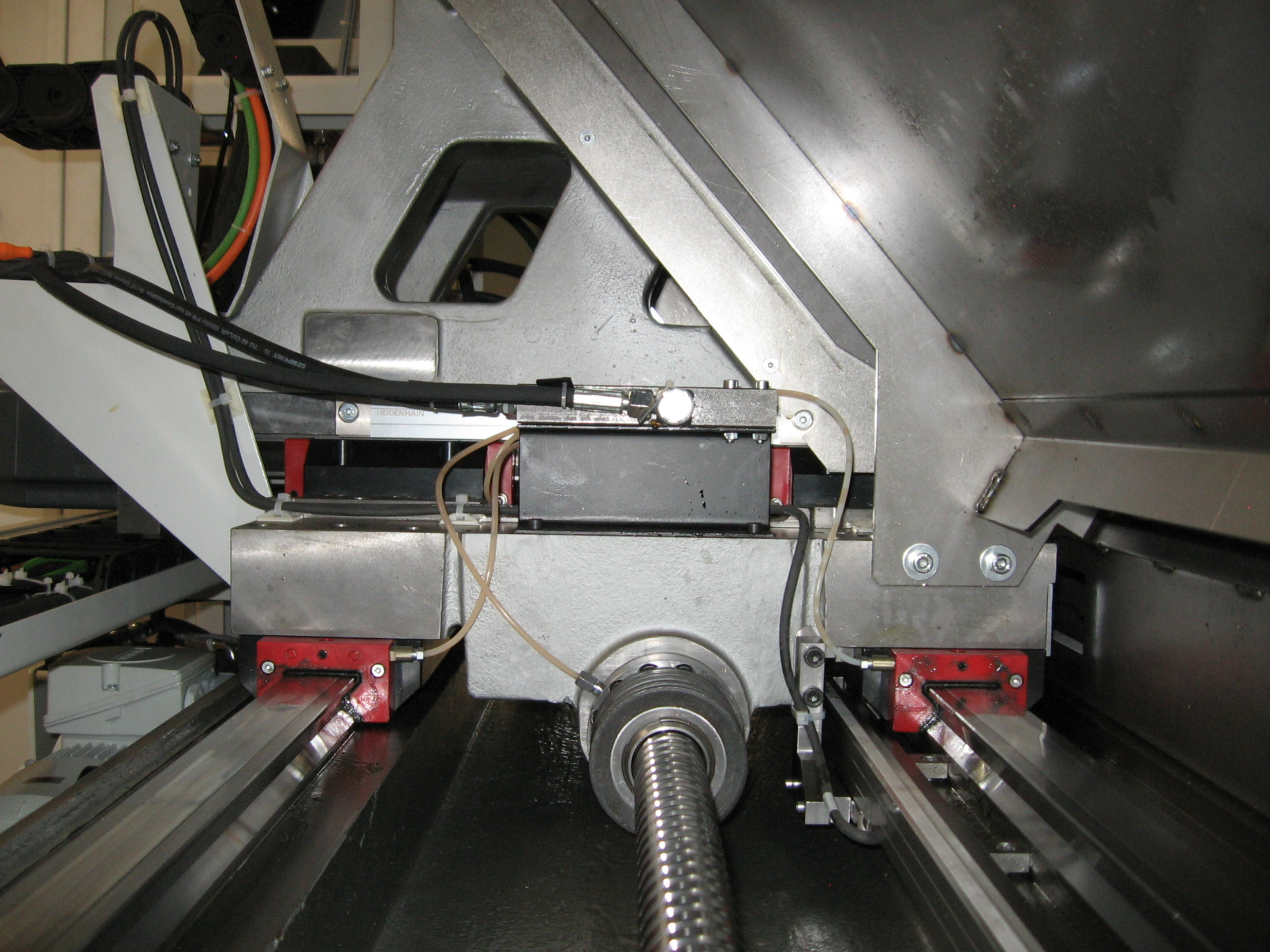

Add to this the C-axes with independent servomotors for achieving precise and stable work piece positioning, linear roller guide ways with bearing capacity dimensioned for hard roughing but also precision of finishing operations, while increased spindle bores extend the machining possibilities for a wider assortment of work pieces.

The integrated control panel improves machine control ergonomics for the operator, while programming in 3D through cycles is provided.

Servo drives with electric energy saving features and an option for industrial robot integration for manipulation of raw material and work pieces add to an impressive line-up.

The SBX500 DoubleTurn M.C.Y features a max swing diameter of 650 mm, max turning diameter of 550 mm and a max bar diameter of 74/117* mm. The max diameter of bars with spindle reduction sleeve or with spindle prolongation is 66/103* mm.

The max weight of workpiece in centres is 1000 kg with the max weight of overhung workpiece 372 kg.

*valid for optional execution

For more information, contact 600 SA Machine Tools – Cell: 072 157 6003.