By Peter Frow, CEO of FAS Machine Tools

After a price-performance comparison against imported machines, FAS Machine Tools recently was awarded a contract by a Pretoria company for the supply of a 7-axis Synchronette CNC lathe to manufacture male and female pins for multi-pin plugs.

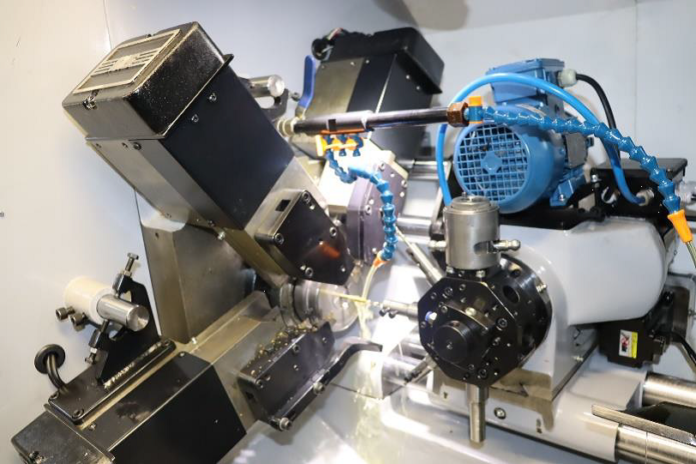

The specification of the Synchronette was a perfect match for the application as the machine boasts extremely quick cycle times, due to its ability to have as many as four tools working simultaneously on the workpiece. Also, the unique electromechanical chucking system allows bar feed-up times of less than a second.

The machine features an 8-station turret which moves in two axes, a dedicated turning slide and dedicated forming slide which both move in two axes and a dedicated parting slide. The turret is equipped with live tooling.

For this particular contract the parts are required to come off the machine complete with centring and drilling of the rear of the component. This is achieved by means of the rotating pickup head which transports the semi-finished part to the rear of the machine where a gang-tool array completes the machining of the part.

As the machine is intended to run twenty-four seven, it is equipped with an automatic magazine bar loader so that it can run unattended for extended periods of time.

FAS Machine Tools has larger Synchroturn CNC lathes running successfully in the field, which can handle bar sizes up to 60 mm and are supplied with either 26 mm or 36 mm spindles.

FAS Machine Tools 7-axis CNC lathes are significantly cheaper than equivalent imported machines, almost like a Porsche with a Volkswagen price tag.

For more information on the please see www.faslathe.com or contact FAS Machine Tools on 031 7027318.