Rapidly advancing CNC technology is driving innovation everywhere, especially in CNC machine tools and software. The key to being able to innovate and remain competitive is to take advantage of the technology trends adapting to market demands.

The newest edition to the Hwacheon successful Hi-TECH Line – Hi-TECH 750 is a CNC lathe with 15 – 24” chuck and solid box guide ways in all axis. The creation of the HI-TECH 750 follows the very successful Hi-TECH 850 series which was launched more than ten years ago.

The new Hi-TECH 750 adopts the same successful path as the Hi-TECH 850, where the machine’s standard, variations and options are wide and flexible and can be utilised in practically all industries and applications.

Applications of Horizontal Turning Center Hi-TECH 750

The modern design of Hi-TECH 750 gives a clear signal to the market, that this is not only a new horizontal turning centre, but also a modern and further enhanced machine specifically designed following market and customers’ feedbacks and application needs. While standard 2-axis to multi-axis machining including the requirements for modern manufacturing have been considered, the flexibility of the H-TECH 750 provides multi-axis turning for large shaft type application and complex parts which require turning OD & ID as well as milling, drilling and tapping operations. From standard steel to modern tough materials such as Inconel, titanium, stainless steel, high tensile stainless steel, the extraordinary machine structure and design will be the basis for all variations and applications demands.

Key Features of Horizontal Turning Center Hi-TECH 750

Following the Hwacheon principle, key functions come as standard and are included at no extra cost, such as the precision main spindle including an oil-jet lubrication system for bearings including a high capacity oil cooling and filter unit

The machine is supplied with a powerful direct main drive and gear box (no belt drive) featuring up to 45Kw and up to 6,560Nm torque, subject to the CNC control system selected.

Other key features are a high capacity milling drive system up to 11.3Kw and 215Nm torque plus a 280mm wide turret disk, including twelve (12) stations with BMT 85 tooling holder as standard.

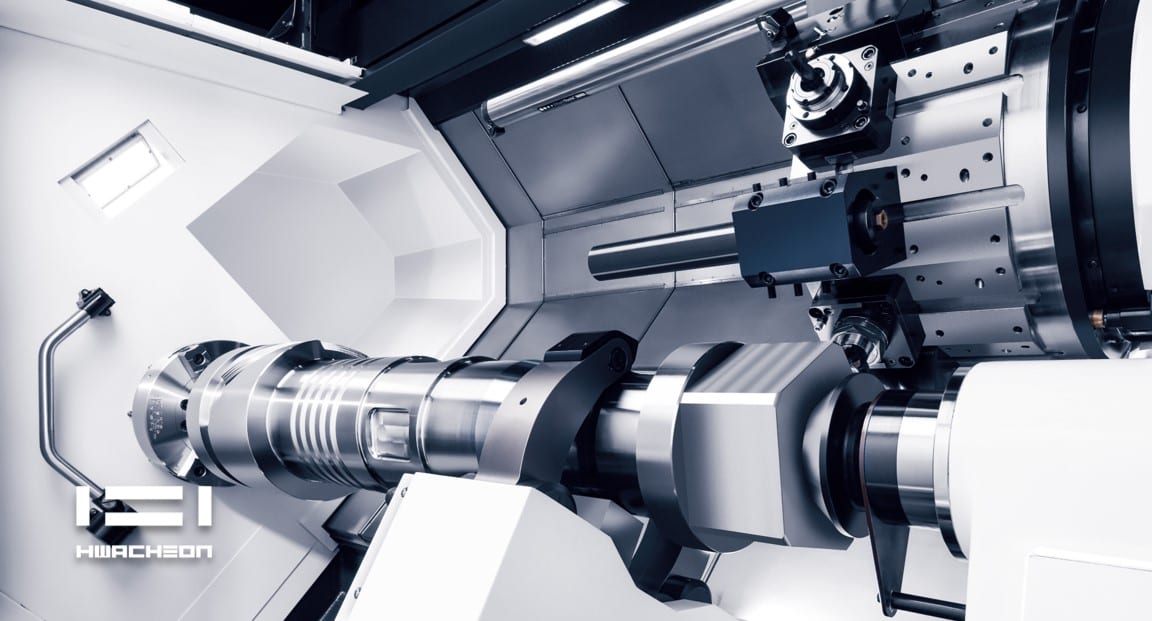

The programmable built-in tailstock which provides not only a very rigid and solid support to even the most heavy workpieces, compensates automatically for the growth and shrinking rate of a warming and cooling workpiece. Available spindle bore sizes are diameter 132mm or 185mm, resulting in a bar size of 116 or 164mm, respectively, while big bore versions will follow suit.

Available spindle bore sizes are diameter 132mm or 185mm, resulting in a bar size of 116 or 164mm, respectively, while big bore versions will follow suit.

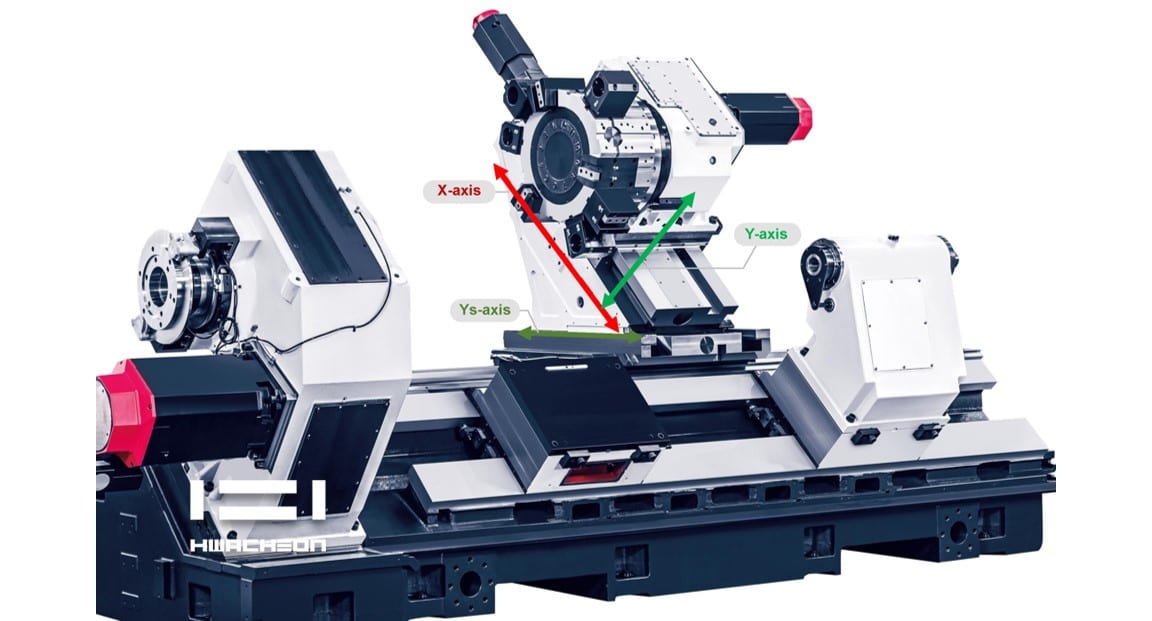

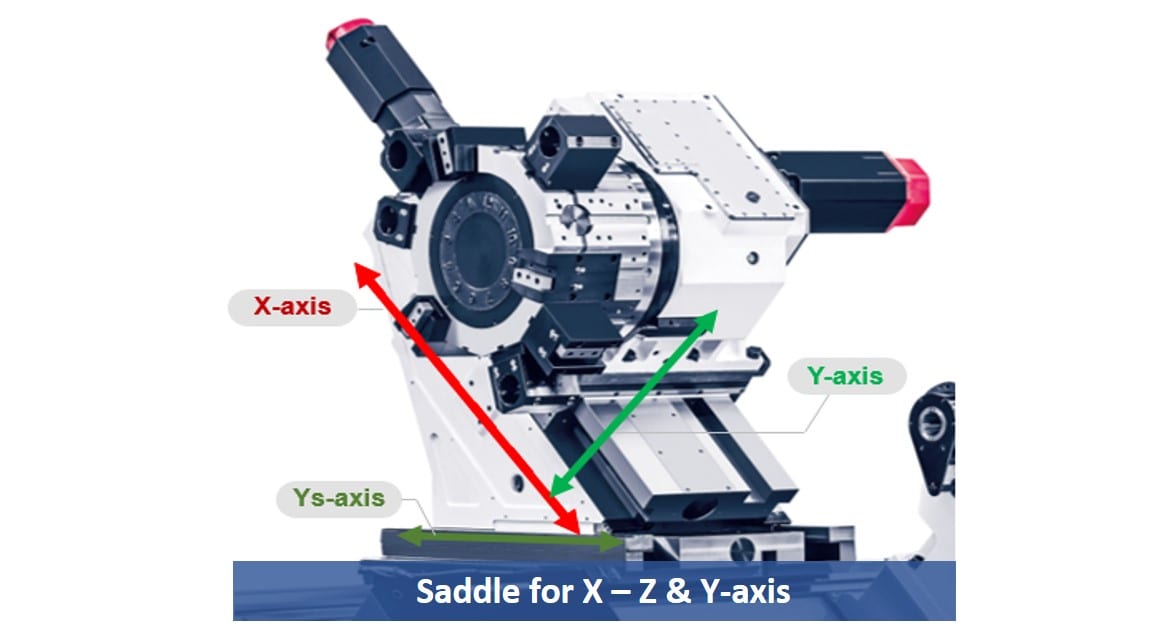

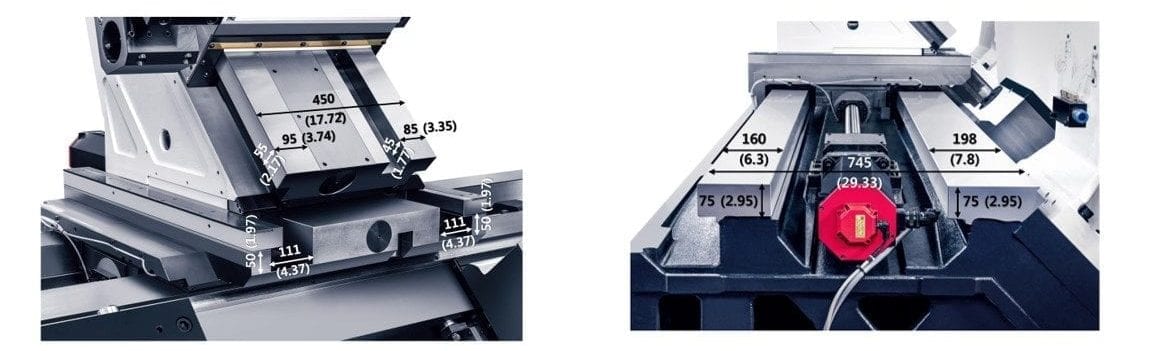

The Hi-TECH 750 horizontal turning center features not only a simple slant bed design but a trapezoidal-designed machine bed. The strong and dynamic tailstock is mounted at the slant bed section of the machine and so is the optionally available steady rest base for hydraulic as well as standard manual steady rest versions. The unit for X – Z and Y-axis is mounted on a solid flat-bed design to ensure highest stability and accuracy at all times and conditions. The triangular saddle is a highly optimized unit where the Y-axis can perform without limitations or chattering or weaker performance results.The basic machine bed weight for our Hi-TECH 750 short version (2,250m) is 8 tons, while featuring a high quality meehanite casting, extra wide guide way designs and sizes, providing extreme stable cutting conditions. Available length sizes are 2.25m / 3.25m & 4.25m.

The triangular saddle is a highly optimized unit where the Y-axis can perform without limitations or chattering or weaker performance results.The basic machine bed weight for our Hi-TECH 750 short version (2,250m) is 8 tons, while featuring a high quality meehanite casting, extra wide guide way designs and sizes, providing extreme stable cutting conditions. Available length sizes are 2.25m / 3.25m & 4.25m.

Enhanced user convenience is provided through new designed spindle drive system which is bringing the machines main spindle centre closer to the operator (546.5mm), while optionally available is a modern programmable steady rest base, providing everything a customer would need to use a manual or hydraulic steady rest of various make and sizes. Customer can choose a bracket where the steady rest can be mounted at left or right side or if preferred for ultimo flexibility at both sides

Customer can choose a bracket where the steady rest can be mounted at left or right side or if preferred for ultimo flexibility at both sides

A large and deep pocket (above spindle / chuck) is providing easy operation for long boring bars. Users worldwide appreciate that large and long boring bars (up-to max. diam. 80 x 800mm) can be left mounted at turret unit and still standard operations are possible to conduct with other tools mounted at turret. Larger and longer boring bar solutions are available at on request.

The large dimensioned front doors of Hi-TECH 750 provide wide dimensioned safety windows for easy view during operation, while an optional auto door function is available.Maintenance is made easy as coolant tank and chip conveyor can be moved out from under the machine to the front.

For more information, contact Lead Machine Tools – Tel: 021 534-5351

![Even-Better-Performance-Hi-Tech-750-2[1]](https://machinetoolmarket.co.za/wp-content/uploads/2021/03/Even-Better-Performance-Hi-Tech-750-21-696x375.jpg)