FANUC ROBODRILL α -DIB5 PLUS SERIES

Further productivity enhancement with the same trusted reliability

It is already hard to improve upon such a well-balanced design. The new α-DiB5 Plus Series Robodrill therefore uses the same time-tested and trusted mechanical design while boasting the latest in FANUC CNC and Servo Technology.

FANUC 31i-B5 Plus Control Powerhouse

The new-generation CNC control offers many features as standard along with new intuitive iHMI screens. The Plus control now offers 4MB of part program storage as standard with the option of upgrading to 8MB. High speed skip is now a standard feature ensuring touch probe signals are as true as possible. Furthermore, Multi-functional ethernet eases the step to fully automate your Robodrill when the time comes to add a FANUC ROBOT. Smart rigid tapping cycle utilizes the maximum output of the spindle without compromising on accuracy and Smart overlap function overlaps command blocks between rapid traverse and cutting feed blocks to avoid speed loss at transition points.

Level-up of Ease-of-Use Screens

Not only are the conventional screens still available to make the transition easier to the latest Robodrill, but there is a whole array of new and improved screens to assist operators with Maintenance, Zero Position Recovery, Turret Restoration, Machining Cycle and CNC operation functions. These screens have step by step instructions and are intuitive in nature.

The iHMI Machining Cycle screens (Previously Manual Guide i) has been revamped and is now more capable of generating complex drawings while also being more user friendly.

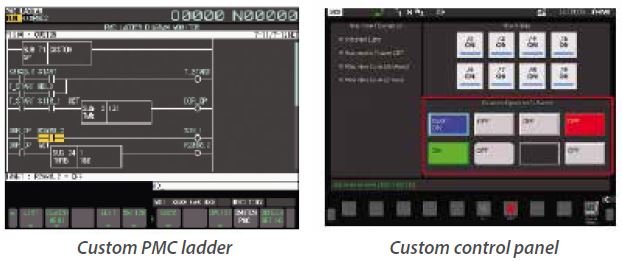

The control is also capable of displaying up to 15 custom screens which can be used for your Robot automation project, pallet changer or precision measurement equipment. Custom-made switches and clamping setups can even be controlled with the use of the Custom PMC Ladder and the external interface screens enabling the user to program touch screen buttons to manipulate physical external equipment. This puts the power into users’ hands and makes the Robodrill the most versatile option when tackling automation projects.

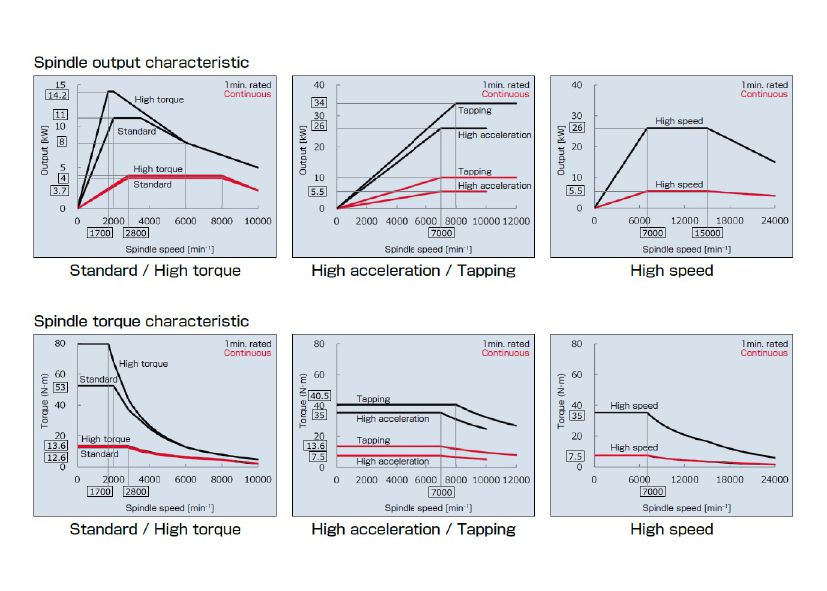

Revised Spindle Line-up

The new 12,000 RPM Tapping spindle which taps perfectly in between our High Power Speed 24,000 RPM spindle and the Robodrill’s robust High Torque 10,000 RPM spindle opens a new spectrum of applications. Aluminium automobile, IT Parts and electrical parts are just some of the parts in which the Tapping spindle will come into to its own. This spindle in conjunction with the Smart functionality will yield the best results possible.

Spindle torque characteristic

FANUCs legendary reliability coupled with easy preventative maintenance procedures keeps downtime to an absolute minimum. And thanks to their extreme longevity, ROBODRILL machines also provide an unbeatable return on investment.

FANUC ROBODRILL is proudly made in Japan and comes with a 2 year mechanical and control warranty. The FANUC ROBODRILL α-DiB5 Plus series is available from FANUC South Africa.

For more information, please contact FANUC South Africa Sales on 011 392 3610, e-mail sales@fanuc.co.za or visit www.fanuc.co.za.