By Paul Savides, PBS Machine Tools

The current difficulties faced by manufacturing industries worldwide include a skills shortage caused by a slowing population growth rate, unhealthy dirty and dangerous working environments plus work-life balance initiatives and rising wages.

Circumstances that affect work performance have led the industry to gradually introduce automation to replace manpower. Corresponding to different production modes, unique situations need to be considered when introducing automation for any particular approach.

While in mass production, fixed products are produced over long hours, total accumulated load/unload time has a substantial impact on output. Time saving is of paramount importance and therefore, the introduction of suitable feeding units, such as robots is advisable.

If a production run involves variables, changing the line quickly is another important point to be considered. Additionally to equipment, project management and planning needs utmost focus.

Introduction of automation can bring a lot of benefits yet, sometimes after an investment, technical problems are found or maybe output is just not as good as what was expected. If the process is not perfect, any necessary modifications will force the production line to be stopped. Any defects found may be difficult to remedy if the system is complex or modifications may be extremely costly to integrate.

Therefore, Tongtai considers all possible problems from the very outset of planning, while identifying them by thorough analysis, evaluation, software and hardware integration and data management.

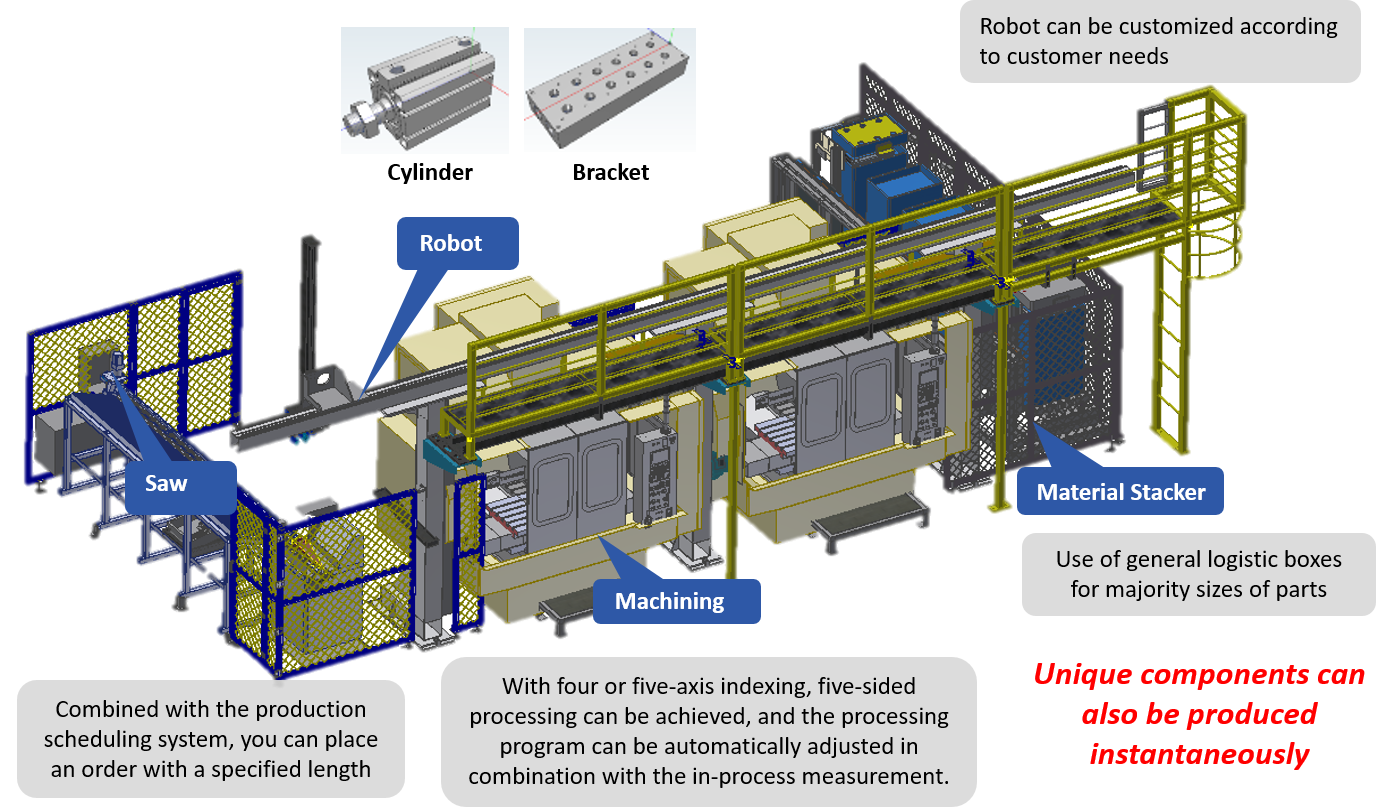

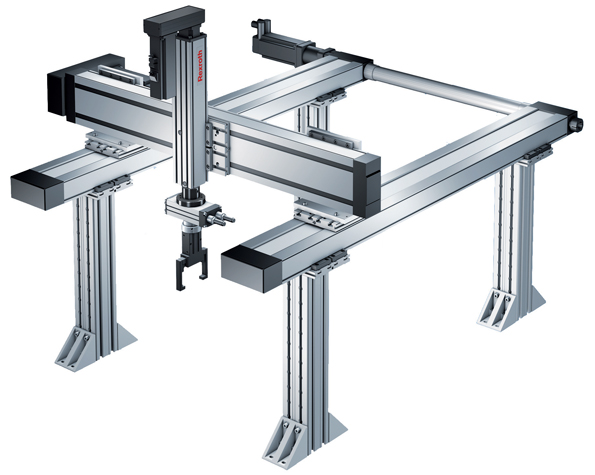

Hardware equipment to meet “Production Line Automation”

Tongtai supplies loading and unloading equipment, as well as peripheral devices used for testing, measuring and logistics which are most suitable for customers’ production line needs.

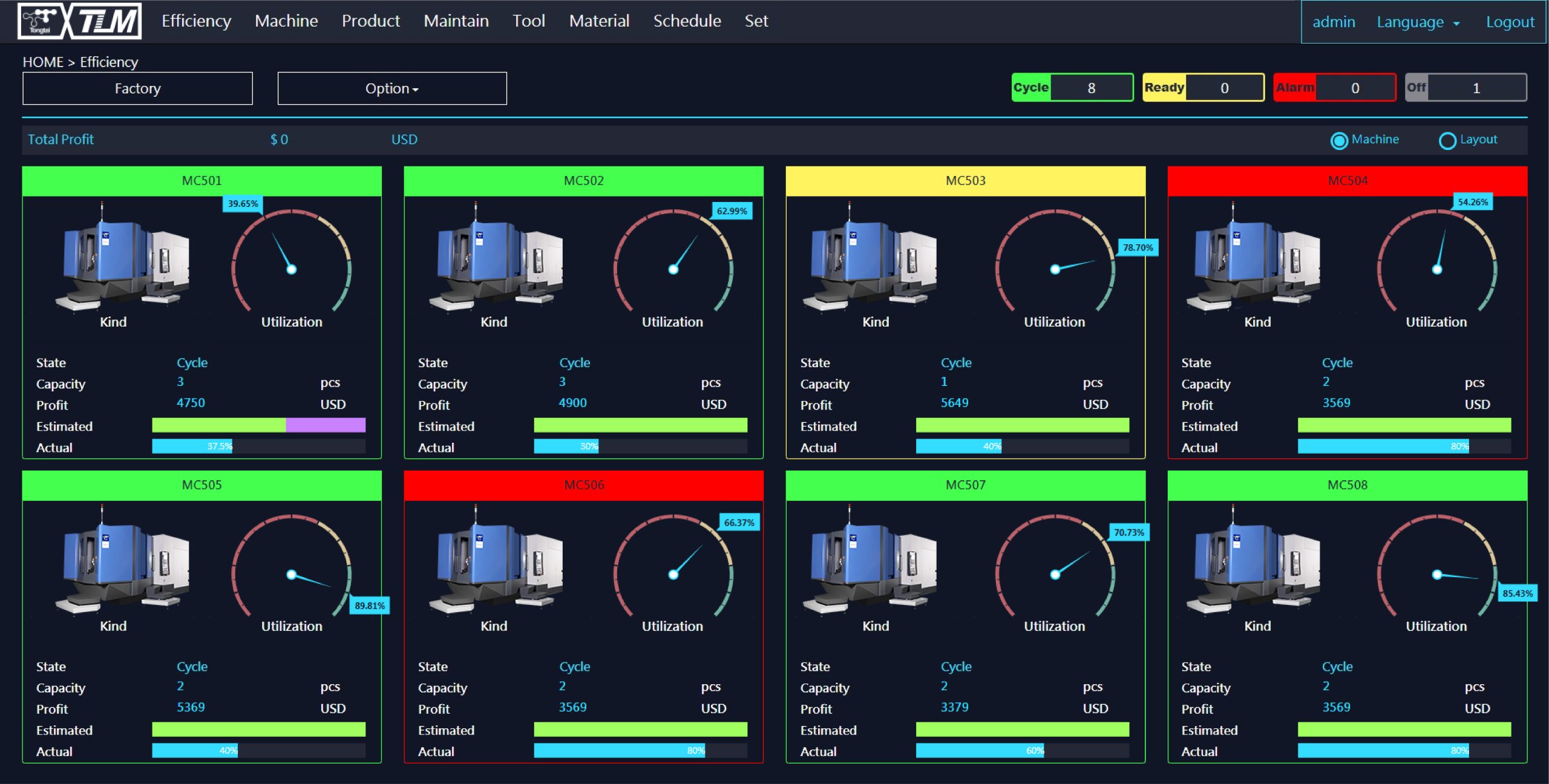

Software system to meet Information Automation

In response to historical production and management problems, Tongtai has developed a series of software programs that enhance the Human Machine Interface (HMI), including TIHMI and TIMS which make Tongtai machines intelligent, while vastly improving efficiency and TLM whole line management software which provides real-time data of production line status.

Data Management

Management Tools to Satisfy “Management Automation”

The following is an example of a customized HMLV Tongtai manufacturing line:

This multi-variable production line can be reconfigured to quickly process any length of material, even bringing a single workpiece into the system, for immediate production before returning to a previous batch.

For more information please contact PBS Machine Tools – Tel: 011 914-3360.