Profiling with solid carbide ball type end mills on 5-axis machines has disadvantages, such as excessive machining time and poor surface finish. To solve these problems, TaeguTec introduced oval and lens shape solid carbide heads that are 3D profiling capable.

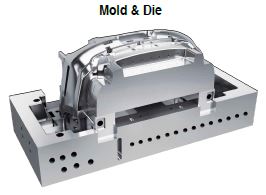

The new heads are designed for high-pitch, semi-finishing and finishing profiling parts used in the aerospace, power generation, medical and mould & die industries.

Even in high pitch conditions, the same surface finish can be obtained compared to solid carbide ball type end mills, and therefore the new heads are capable of high productivity machining.

Features include reduced machining time, increased productivity and similar surface finish even in higher pitch conditions compared to solid carbide ball type end mills, while in the same pitch and machining time conditions, solid carbide heads provide better surface finish over solid carbide ball type end mills. With the wider cutting edge contact improved machining stability and longer tool life is provided making it ideal for machining difficult-to-cut materials such as titanium alloy, Inconel and stainless steel.

For more information please contact TaeguTec – Tel: 011 362 1500.