Bystronic’s Gerrit Gerritsen, Product Manager Bending & Automation describes the benefits of a fully automatic bending cell.

Not so long ago, automation was associated only with repetitive tasks. High – and consistent quality, as well as reliability over very long periods are decisive factors that ensure the profitability of automation in production environments. However, more complex jobs that require a high degree of customization in the manufacturing process are still often performed manually. This is currently a widespread approach in the sheet metal processing sector.

However, our industry has experienced a major transformation over the past five years – indeed, one could say it has been forced to transform. Increasing price pressure in the markets and the lack of skilled personnel are just two of the reasons for this, in addition to increasingly dynamic and uncertain business environments.

It cannot be completely dismissed that both, manual processing by a human operator and automated manufacturing, each have their advantages and disadvantages. Accordingly, every decision in favour of or against automating a process is a balancing act involving many production-relevant variables. In addition to productivity and quality, flexibility is an undeniable competitive advantage of any supplier in the manufacturing industry, especially in view of increasingly dynamic business environments.

This is a dilemma that has led to a backlog of automation, especially in the sheet metal processing industry, however, when users do not wish to accept any compromises in terms of flexibility, productivity and consistently high quality, the demands on the machines increase.

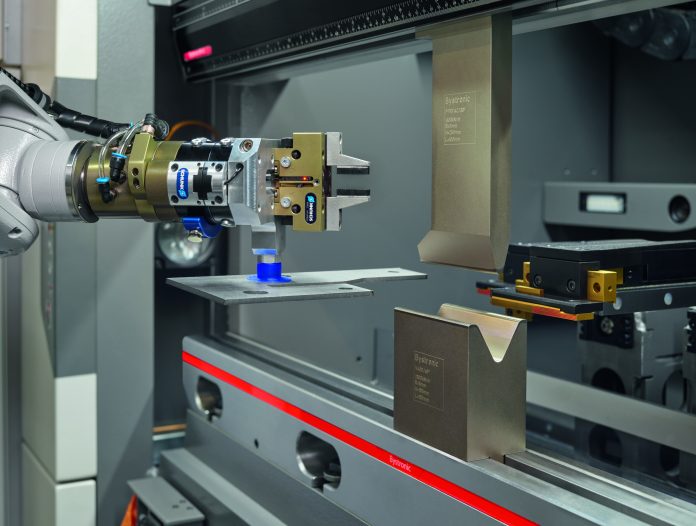

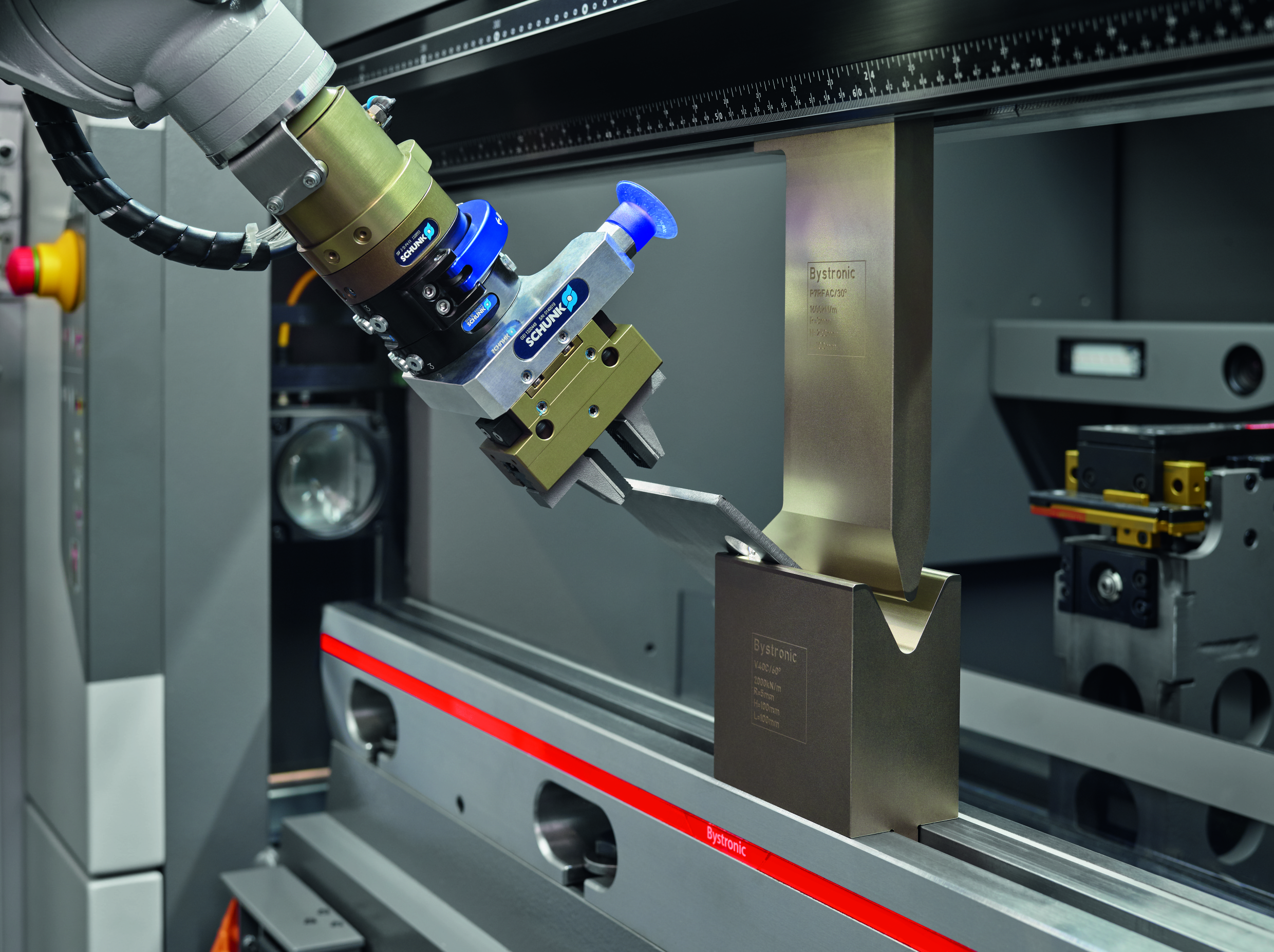

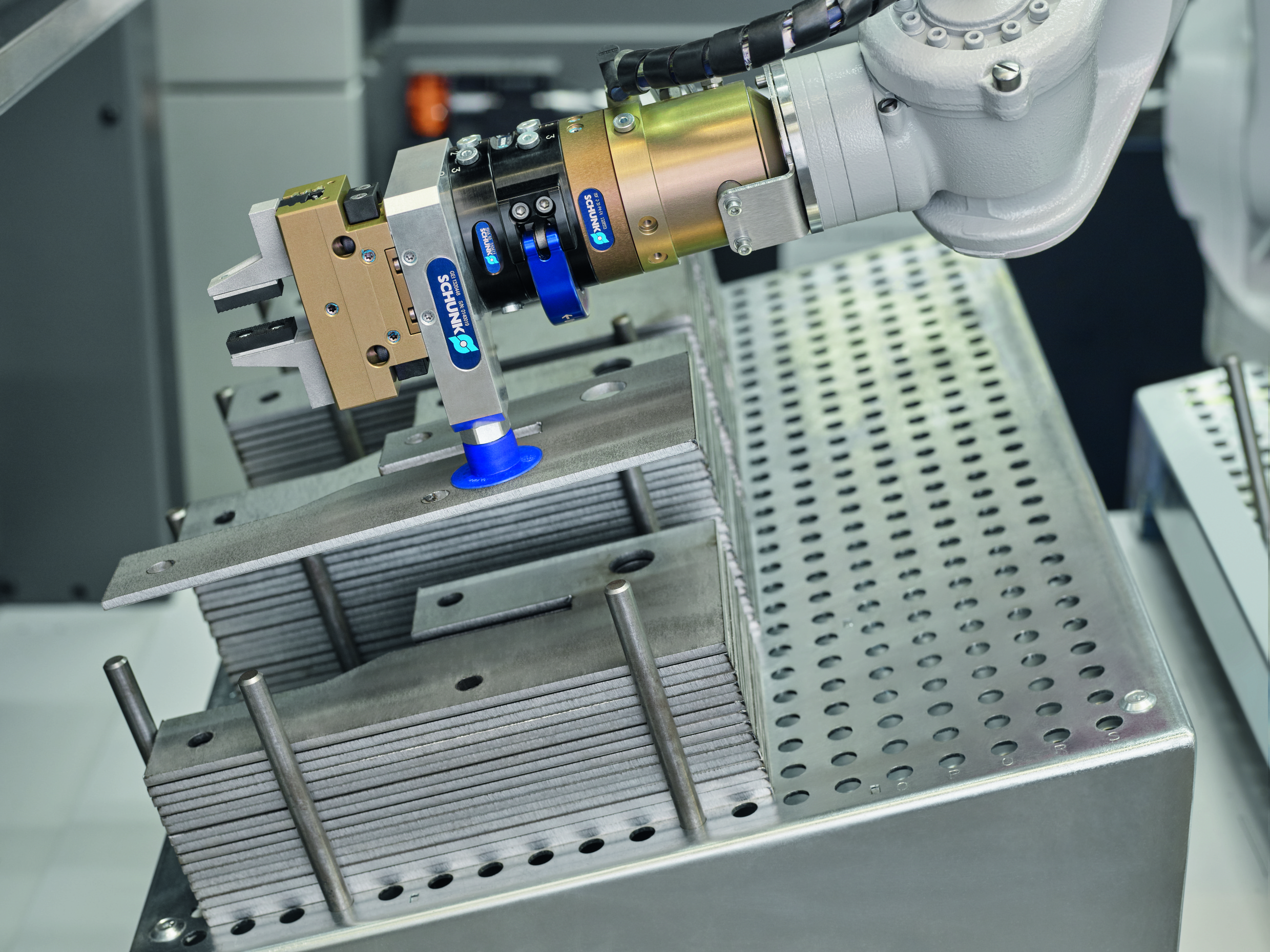

Bystronic’s Mobile Bending Cell addresses these demands and implements them by applying intelligent technology. In short, the solution is called automation on demand. The users’ requirements are particularly wide-ranging when it comes to bending technology. Being able to bend parts with extremely complex geometries in small batches while simultaneously being capable of handling the high-volume processing of simple geometries is a major challenge that many companies are currently facing. The Mobile Bending Cell combines the demand for both, extremely high flexibility, as well as high quality and productivity.

This is achieved by means of the Mobile Bending Robot, which can be positioned in front of the press brake or detached to allow manual operation. Thanks to an intelligent and fully automated measuring system, the robot references itself in front of the press brake without requiring manual intervention. Laser sensors measure the precise position of the robot relative to the press brake and reference it accordingly. This allows the press brake to be converted from manual bending to fully automated bending in less than ten minutes. The relative position of the press brake to the Mobile Bending Robot is determined so accurately that the need for manual calibration is completely eliminated.

Once individual parts have been bent automatically in the past, the process can be repeated without adjustments once the press brake and the Mobile Bending Robot have been connected. Depending on the requirements, the system can either be operated completely manually or fully automatically.

However, the “marriage” of press brake and Mobile Bending Robot is not the only critical factor for an efficient production process. The preparation of the parts that are to be bent is another process that incurs costs in every production run. For the automation on demand concept to really pay off, the process of programming the robot automation needs to be innovative and fast. The Mobile Bending Cell’s programming system is called Robot Manager. The robot’s movements are programmed using algorithms that factor in comprehensive collision models for each relevant application. All that is required is the definition of basic positions; all the other movements are automatically defined by the software. This increases quality while reducing process idle times.

Automatic measurement of the press brake and bending automation system in combination with intelligent robot programming makes the Mobile Bending Cell the ideal solution for bending automation on demand.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.