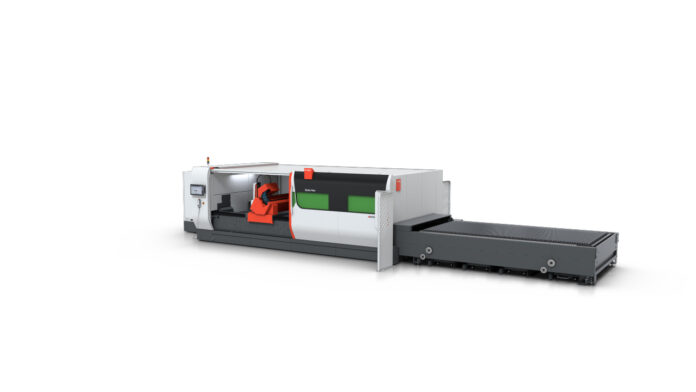

The flagship of Bystronic’s laser cutting systems is available with 20 kilowatts of laser power and optimized cutting process. Its latest-generation cutting head was developed to achieve consistently high quality with the highest laser outputs and for demanding cutting applications. This enables sheet metal processing companies to further optimize their production.

Enhanced cutting quality and productivity thanks to the new, even higher laser power

In order to offer sheet metal processing companies even more effective support in an increasingly competitive environment, Bystronic recently advanced into a new dimension of fiber laser cutting, the 20 kilowatt ByStar Fiber. The high-end fiber laser represents high-precision Bystronic technology, a reliable cutting process even with the highest laser outputs and a wide range of applications. This enables sheet metal processing companies to take another major step forward in terms of productivity and efficiency. The technological leap from the previously available 3 to 15 kilowatt laser output levels to the latest 20 kilowatt level is considerable and opens up new possibilities for Bystronic’s customers to optimize their production and thus remain one step ahead of the increasingly fierce competition.

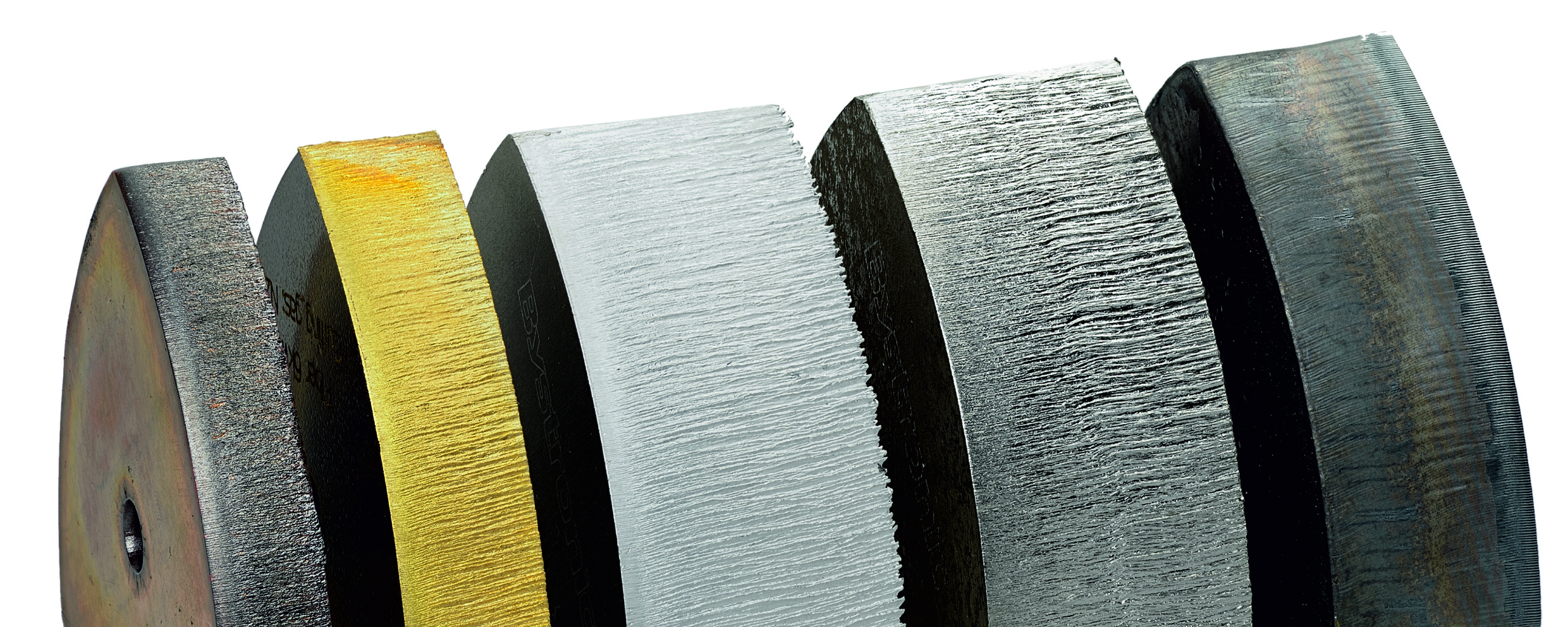

Speed for an extended cutting spectrum

Compared to 15 kilowatts, the productivity of the 20 kilowatt ByStar Fiber are on average 40% in mild steel and stainless steel 4 mm to 20 mm. This means that sheet metal processing companies can benefit from higher productivity at low unit costs, because thanks to its 20 kilowatts, the ByStar Fiber cuts steel, aluminium and stainless steel precisely and reliably. The 20 kilowatts of laser power thus enable maximum flexibility for both large series and urgent customer orders. Regardless of whether cutting aluminium, non-ferrous metals or steel, the high-performance Bystronic cutting head excels with maximum precision in both, thin and thick sheets and profiles. In addition, the 20 kilowatts open up extended applications in steel and aluminium of up to 50 mm.

The optional «Parameter Wizard» ensures that the correct quality of cut parts is always selected by obtaining the perfect parameter within minutes.

The new power level is available for the ByStar 3015, 4020, 6225 and 8025.

Bystronic’s high-performance flagship is controlled using the ByVision Cutting software via a 21.5-inch touch screen. Operating the machine is as simple as using a smartphone.

Bystronic automation solutions optimize the material flow

A wide range of automation solutions guarantees maximum machine utilization and process reliability even during unmanned operation. In order to ensure an optimal material flow that makes full use of the high laser cutting speeds, Bystronic offers a wide range of automation solutions for the ByStar Fiber. These include loading and unloading systems, sorting solutions, and individually customizable storage systems. This makes it possible to create an automated laser cutting process that is seamlessly integrated and adapted to the existing production environment and available space.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.