Easy to use NC Merge feature in Hurco’s conversational control software means CAD/CAM is only needed for programming complex 3D contours

Six Hurco 3-axis VMCs carry out a majority of prismatic machining in the toolroom at the headquarters of plastic packaging manufacturer Berry M&H in Beccles, Suffolk. Although the firm dates back to 1973, the first Hurco machines, a VM10i and a VMX30i, did not arrive until 2015 when the assets of another toolmaking company were acquired, including its machines.

Prior to that, manual knee-type mills were followed by 3-axis CNC milling machines and then a succession of machining centres with automatic tool change. All of the CNC machines, although of various makes, were fitted with the same G-code-based brand of control system to provide commonality for the convenience of the staff.

Berry M&H’s toolroom manager Kurt Knights, who has been with the company for over 20 years advised, “When we started using WinMax conversational software in the Hurco control, it made shop floor programming far easier and quicker for our operators – and it also simplified training new people.

“Most programs we prepare take advantage of the Hurco’s NC Merge feature. Complex parts of a cycle for contour-milling 3D mould surfaces are output from either NCG CAM or SolidWorks CAD/CAM systems in our design department and the file is imported directly into the control.

“Conversationally programmed blocks prepared at the machine using WinMax are then automatically merged in the control with the offline content into a single program for milling the block parts of our moulds.”

Offline code generation for a mould takes typically 10 hours, while the shop floor element is completed in around two hours, much faster and more simply than is possible on a machining centre driven by a G-code control. It quickly became apparent that the Hurco/WinMax combination was perfect for Berry M&H’s requirements, which centre mainly on fast-turnaround production of moulds from 170 mm wide Alumec 89 billets. Most moulds comprise neck, body and base blocks manufactured from this high strength aluminium alloy, held together by a steel back plate.

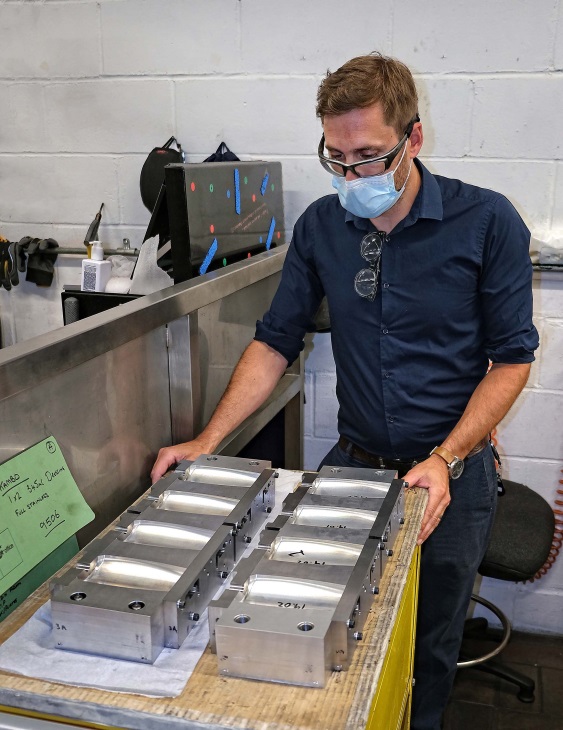

Two new Hurco VM5i 3-axis VMCs were purchased for machining these moulds, as well as for new tool development that was formerly the province of the CNC mills, all but one of which have now been sold. The VM5i was chosen as it has a generous 457 x 356 x 356 mm working volume in a compact 1.6 x 2.9 metre footprint. It suited the toolroom space and layout well and was correctly sized for machining the company’s moulds. Four halves at a time are fixtured, each of which takes about three hours to machine. The resulting 12-hour cycle is more than sufficient for a full light-out shift overnight.

Two new Hurco VM5i 3-axis VMCs were purchased for machining these moulds, as well as for new tool development that was formerly the province of the CNC mills, all but one of which have now been sold. The VM5i was chosen as it has a generous 457 x 356 x 356 mm working volume in a compact 1.6 x 2.9 metre footprint. It suited the toolroom space and layout well and was correctly sized for machining the company’s moulds. Four halves at a time are fixtured, each of which takes about three hours to machine. The resulting 12-hour cycle is more than sufficient for a full light-out shift overnight.

As the size and performance of the two VM5i machines were ideal, the decision was taken in 2019 to buy a third, this time for producing items such as printing chucks, bracketry and other general, non-mould items for different departments across the Beccles site. It brought in-house a lot of previously subcontracted milling, delivering considerable financial savings.

In November 2020, a larger Hurco VM30i with a 1,270 x 508 x 508 mm working volume was purchased that Knights described as “a superb machine and excellent value for money”. The investment was down to Berry M&H’s decision to move more strongly into the production of bigger moulds up to 700 mm wide and with up to six cavities.

There had always been a requirement for this size of tool and their production was previously subcontracted out, so this expense is now also saved. Both Alumec 89 and 1.2316 stainless steel are used, the latter as it has good thermal conductivity and wear resistance and is also magnetic, allowing a mould to be clamped conveniently on the bed of a grinding machine.

Berry M&H designs, develops, produces and prints to British Retail Consortium standards a large range of plastic bottles, jars, tubs, flexible tubes, closures, caps and dispensing systems. The packaging solutions are sold into the personal care, healthcare, pharmaceutical, nutritional, pet care, automotive and household product markets.

The company has an extensive range of almost 5,000 standard products and also offers bespoke design, prototyping and moulding services. There are 12 manufacturing sites across the UK, mainland Europe, America and Australia, Beccles being the headquarters. Knights’ department produces blow moulds and injection moulds for all of the group’s factories, except for the Australian site.

For more information, contact Hurco – Tel: (011) 012 259 1375