With rising energy costs and strict international environmental laws, equipment efficiency is a key factor that can influence the production costs. By this trend, the latest machine tools not only need to satisfy the requirements of high speed and high precision, but also need to pursue the goals of high efficiency and environmental protection. In recent years, Tongtai has worked hard on developing products which are environmentally friendly. Furthermore, energy saving accessory products are a primary concern to this manufacturer.

Rigidity is better than the past

All components are made of high quality cast-iron, while due to its excellent design, the structure decreases the influences of distortion and vibration. In addition, by applying Finite Element Analysis (FEA) the structure is optimized satisfying the requirements of high dynamic rigidity and stability.

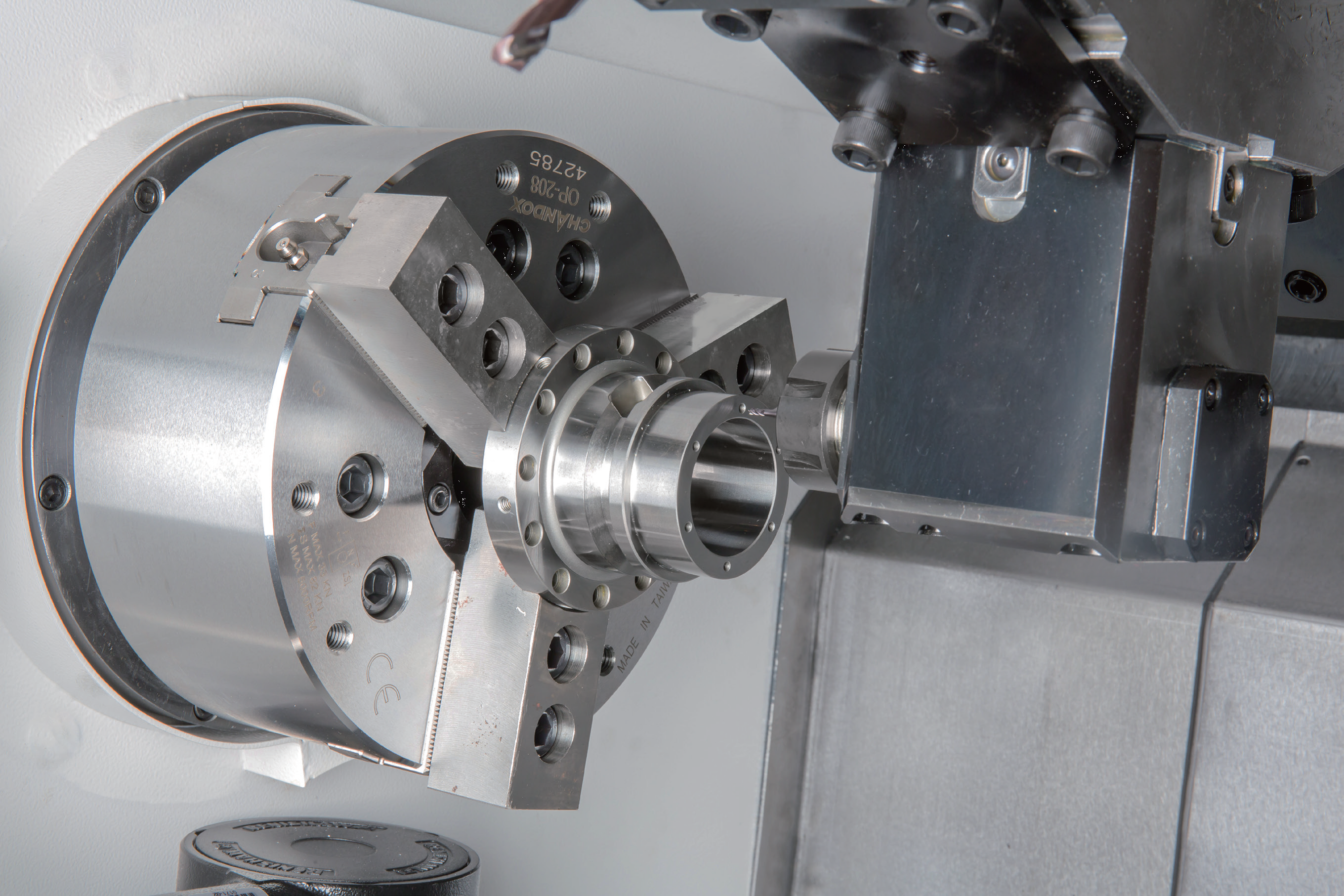

Inheriting the outstanding machine rigidity from TB series, the TD series is the brand new multi-tasking turning center with single power turret which is standard equipped with 12 tool stations and linear Y axis to process milling functions. In addition, the 16 tool stations turret and sub-spindle are also available for more complex machining processes, while helping to reduce labour costs and increasing floor utility.

Spindle/Sub-spindle CS axis with brake unit

The CS axis is fed back by a rotary encoder with multi-points positioning function. The minimum indexing increment of 0.001 degrees allows various machining needs with different angles.

The CS axis is fed back by a rotary encoder with multi-points positioning function. The minimum indexing increment of 0.001 degrees allows various machining needs with different angles.

With synchronous temperature control, the spindle cooler prevents sub-spindle from thermal distortion. This ensures high precision machining for long-term operation.

75 degree machine bed structure

Different from the 90 degree slant bed on TB series, the TD series features a 75 degree slant bed design. It not only keeps the advantages of excellent chip disposal and accessibility, but also lowers the machine’s gravity center, while enhancing the entire structure rigidity.

Linear Y axis structure

The TD series features a symmetrical saddle design, while the X/Y/Z axes are perpendicular to each other with a real linear Y axis. It allows servo compensation on each axis to optimize the positioning accuracy.

Different from the virtual Y axis, the real Y axis has excellent straightness and positioning accuracy which is able to ensure high machining quality. With a highly rigid sliding carrier design, the TD series has outstanding machining capability.

For more information please contact PBS Machine Tools – Tel: 011 914-3360.