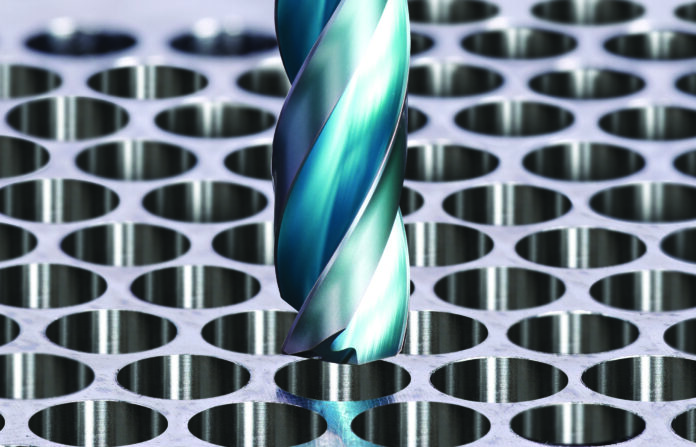

In order to maximize customer profitability by improving productivity as well as superior machining, TaeguTec offers a 3 flute carbide drill with a unique geometry. Not only does the line improve productivity due to the increased number of teeth compared to conventional drills, it also improves machining stability in high cutting conditions with its excellent edge design. It is the best solution for customers who demand excellent performance, especially in steel and cast iron machining.

Features

- 3 flutes geometry improves productivity by more than 50%

- Highest machining stability due to its unique edge geometry

- Reduced cutting load

- Minimized heat generation during machining

- Internal coolant through type

- TT5130 grade

- Sub-micron PVD grade with a good balance between toughness and hardness

- Newly developed multilayer coating structure to strengthen against both fracture toughness and wear resistance

- Excellent hole precision due to its superior self-centring capability

- The latest coating grade for excellent tool life (TT5130)

- Suitable for steel and cast iron machining

- Drill diameter range – 4.0-12.0 mm (3xD and 5xD)

For more information please contact TaeguTec – Tel: 011 362-1500.