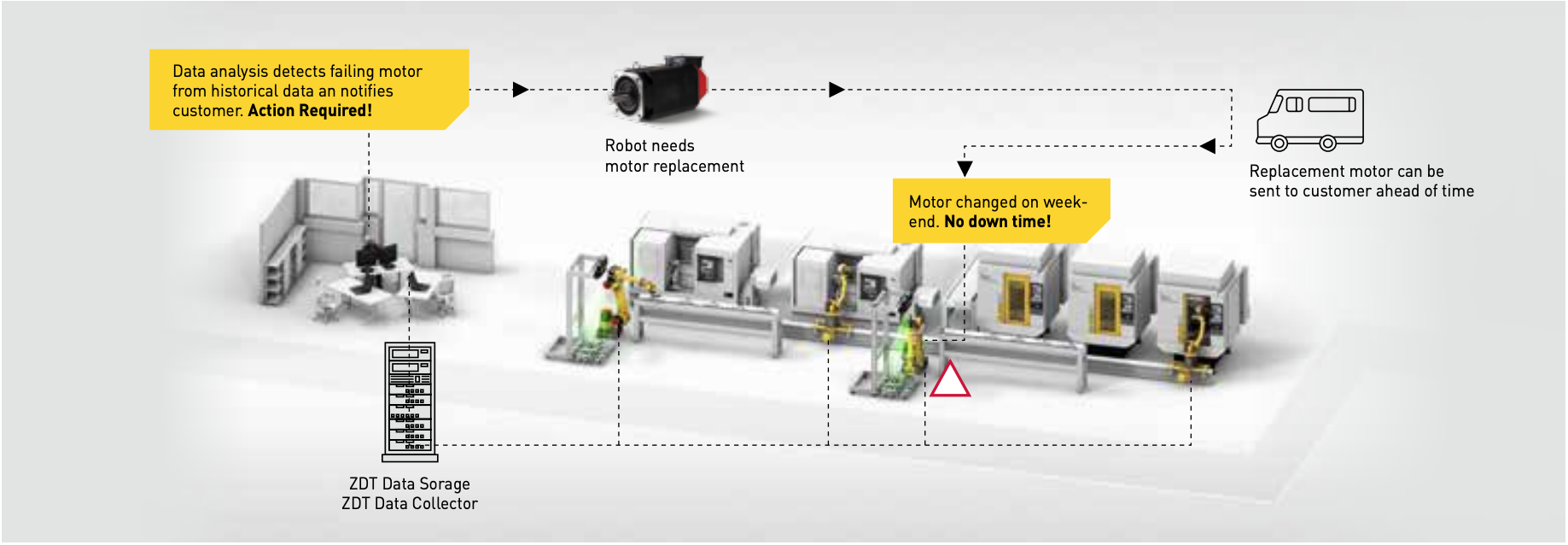

Unexpected downtime is a huge problem to any industry. It can be especially damaging to 24/7 non-stop factories. To address this problem, FANUC is introducing a new software package using technologies of Industry of Things (IoT) or Industry 4.0. This package is called Zero Down Time or ZDT.

The aim of ZDT is to constantly monitor all robots in real time to ensure that downtime doesn’t happen at all. ZDT delivers real time information about:

The aim of ZDT is to constantly monitor all robots in real time to ensure that downtime doesn’t happen at all. ZDT delivers real time information about:

• Mechanical Health

Reducer diagnosis, servo motor and brake health, motor torque monitoring, servo alarm recoding and many more

• Process Health

Operating status, vision detection results, servo gun status for spot welding and many others

• System Health

Error information, memory usage, CPU and network load and many others

• Maintenance Health

Great change time, battery replacement time, lubrication of balancers bushes and other important parts and other maintenance parts.

Great change time, battery replacement time, lubrication of balancers bushes and other important parts and other maintenance parts.

All information can be centrally managed on a server and can be sent in real-time to remote devices such as smartphones and tablets.As well as a robot-only configuration, it is also possible to select the most suitable configuration for your environment, such as a cell-by-cell or factory-by-factory.

ZDT enables enhanced productivity by proactively detecting potential equipment issues before unexpected downtime occurs, while providing advanced analytics and reporting to help optimise equipment utilization in areas such as Smart Maintenance notifications to extend equipment life and optimise maintenance costs and recommendation of actions to extend robot life, reduce cycle times and energy consumption, while offering enhanced technical support services to increase productivity and overall customer satisfaction.

For more information, please contact FANUC South Africa – Tel: 011 392-3610.

For more information, please contact FANUC South Africa – Tel: 011 392-3610.