Thanks to the possibility of 5-axis machining, the CTX beta 800 TC closes the gap to the classical universal lathes as far as the high-performance area in the direction of maximum flexibility for chuck components, such as in mechanical engineering or in the fluid or hydraulics industry.

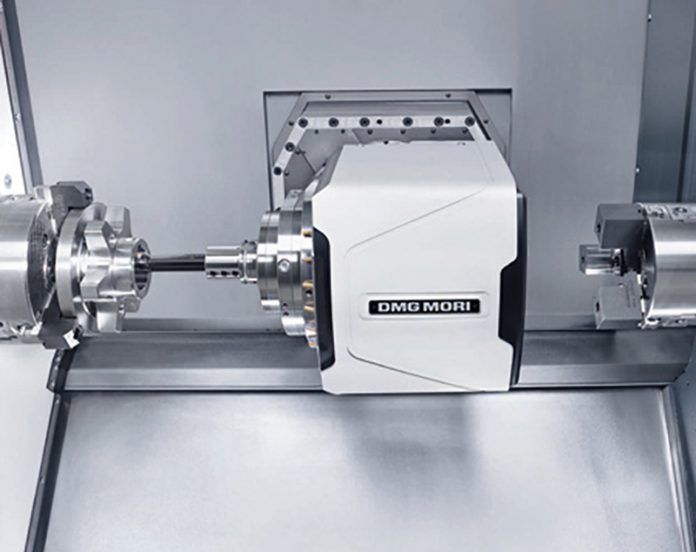

Its automatic tool changer provides outstanding flexibility in classical turning operations involving workpieces up to Ø 500 x 800mm. The highlight of the CTX beta 800 TC is the turning-milling spindle. The Y stroke of 200mm and the new compactMASTER ultra-compact turning-milling spindle open up a wide range of applications to users of Turn & Mill complete machining to the extent of 5-axis simultaneous machining. The compact design of this spindle with integrated release cylinder for the tool clamp makes it possible to have torque of 120 Nm with an impressive length of just 350mm. In comparison with a conventional spindle the increase in work area is 170mm, with 20 percent more torque at the same time. The B-axis is also equipped with a direct drive, which makes highly dynamic machining possible with a swivel range of ±110° and rapid traverse speeds of 70 rpm.

For complex milling operations right through to 5-axis simultaneous machining, the HSK-A63 (optionally Capto C6) compactMASTER turning-milling spindle has performance data of 12,000 rpm, 120 Nm and 22 kW. A 20,000 rpm high-speed version is also available as an option. The DMG Mori high-tech modular building block system allows customers to equip the machine individually in line with their particular range of components. Among other things, this includes different tool magazines with a capacity of up to 80 pockets rather than the 24 as standard.

In the standard version the machine has a main spindle, designed with a liquid-cooled integral spindle motor (ISM76) with 380 Nm and 34 kW or optionally as ISM102 with 770 Nm and 38 kW and an NC-controlled tailstock. The machine can also be equipped with a counter-spindle instead of the tailstock for 6-sided complete machining. The ISM52 PLUS with 6000 rpm and 170 Nm is provided for this purpose. Chucks up to 400mm diameter can be used on the machine in conjunction with the ISM102 spindle motor. Steady rests, available for workpiece diameters of up to 200mm, are recommended for the machining of long workpieces.

The sturdy travelling column design stems from the larger CTX beta 1250 TC and has long since demonstrated its quality. Maximum stability and accuracy are achieved by means of combining with the direct measuring systems in all axes of the travelling column. The machine concept also has impressive ergonomics. Whereas the CTX beta 800 TC has a large work area, its advantages with regard to accessibility and space requirement are also remarkable. The 350mm distance from the front of the machine to the centre of the spindle is the ideal prerequisite for easy loading and unloading. The footprint is just 8.5 mÇ or 10.7 mÇ including chip conveyor.

The potential uses and target groups for the CTX beta 800 TC are manifold. The machine is mainly intended to appeal to the classical user of a universal lathe, which is much more flexible because of the integral tool changer, since there is no need for time-consuming re-tooling on the turret with up to 80 tools. Furthermore, thanks to the B-axis, only low-cost standard tools are required for machining at an angle. The machine has a stroke of ±100mm in the Y-direction, a facility which is not available on any universal lathe in this size category. Possible applications of the CTX beta 800 TC are rounded off by 11 exclusive technology cycles that are optionally available. Using these, up to 60 percent programming time can be achieved by means of extremely simple programming.

For more information, please contact Retecon – Tel: (011) 976-8600.