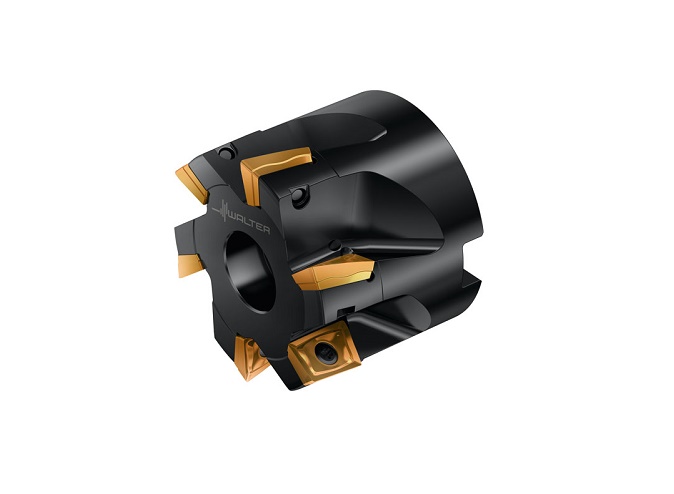

Walter AG is presenting a shoulder milling cutter that is a logical continuation of the M4000 system concept in the form of the M4130. The idea behind this is to reduce costs through the ability to use universal system inserts in different applications and tools. In the case of the M4130, this applies to the system inserts with rhombic basic shape and a 15° clearance angle, which can also be used either in the routing cutters or porcupine milling cutters from the M4000 range. The double-edged inserts with sintered circumference are available in three sizes each with three CVD-coated and three PVD-coated grades. In addition to its high level of flexibility, it also stands out thanks to its cost efficiency.

According to Walter, their soft cutting action makes the M4130 shoulder milling cutters ideal for roughing operations involving steel, cast iron, stainless steels and materials with difficult cutting properties and are also capable of plunge milling. Specifically, these operations are shoulder milling, ramping, pocket milling and circular interpolation milling. The milling cutter with a 90° approach angle is available as standard with depths of cut of 8, 13 and 16mm, in the 16–100mm diameter range. It is also available as a special tool in a considerably wider diameter range. The M4130 milling cutter is part of the Walter Xpress fast delivery range and is manufactured in a CO2-compensated process.

For more information, please contact Spectra Carbide – Tel: 0860 23 23 23.