The Hyundai-Wia L2600SY Multi-Tasking Turning Center features box guideways in all axes, and incorporates a wedge type Y-Axis in the milling mode.

Through the use of the wedge style design, the height of the slide is reduced, and the center of gravity is much closer to the box guideway system. This results in the ability to perform heavy cutting in the Y Axis milling mode, while maintaining precision finishing in the turning mode. With the additional sub-spindle, complex parts can be machined complete in a single setup. The L2600SY features a 10 inch chuck on the main spindle, with a bar capacity of 81mm. Spindle output of 30/25 hp. (max/cont.) provides 440 foot pounds of torque.

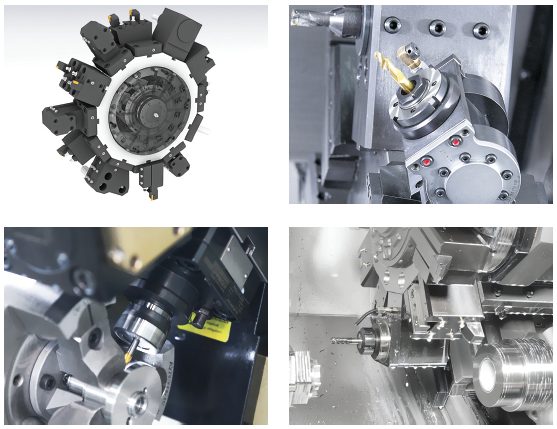

The L2600SY 12 station turret utilizes BMT65 tool blocks and can accommodate either static or rotary tools at each station. Rotary tool speed has been increased to 6,000 rpm, and turret indexing speed is a fast 0.15 seconds, station-to-station. Rapid positioning in the X and Z axis is performed at 1,181 inches/ minute, fastest in its class for a box guideway machine.

The L2600SY 12 station turret utilizes BMT65 tool blocks and can accommodate either static or rotary tools at each station. Rotary tool speed has been increased to 6,000 rpm, and turret indexing speed is a fast 0.15 seconds, station-to-station. Rapid positioning in the X and Z axis is performed at 1,181 inches/ minute, fastest in its class for a box guideway machine.

Standard accessories include part catcher, chip conveyor and Q-Setter. Variant of the L2600SY Multi-Tasking Turning Center includes a tailstock in lieu of a sub-spindle. Optional peripherals include a barfeeder/barloader, special purpose chip conveyor, special parts unloader, high pressure coolant system, part probing, oil separator and mist collector.

Features

- Cycle time reducing structure for productivity

- Integrated processing through synchronized control of main Spindle and sub spindle

- Box guideways in all axes providing long life and for heavy duty machining applications

- Lubrication unit located in the front allowing for ease of maintenance.

For more information, contact Rothco – Tel: (011) 970-1930.