A TRUMPF machine for getting started with laser tube processing or as an addition to existing machinery – Cost-effective even with low capacity utilization – Easy to operate thanks to numerous automated features

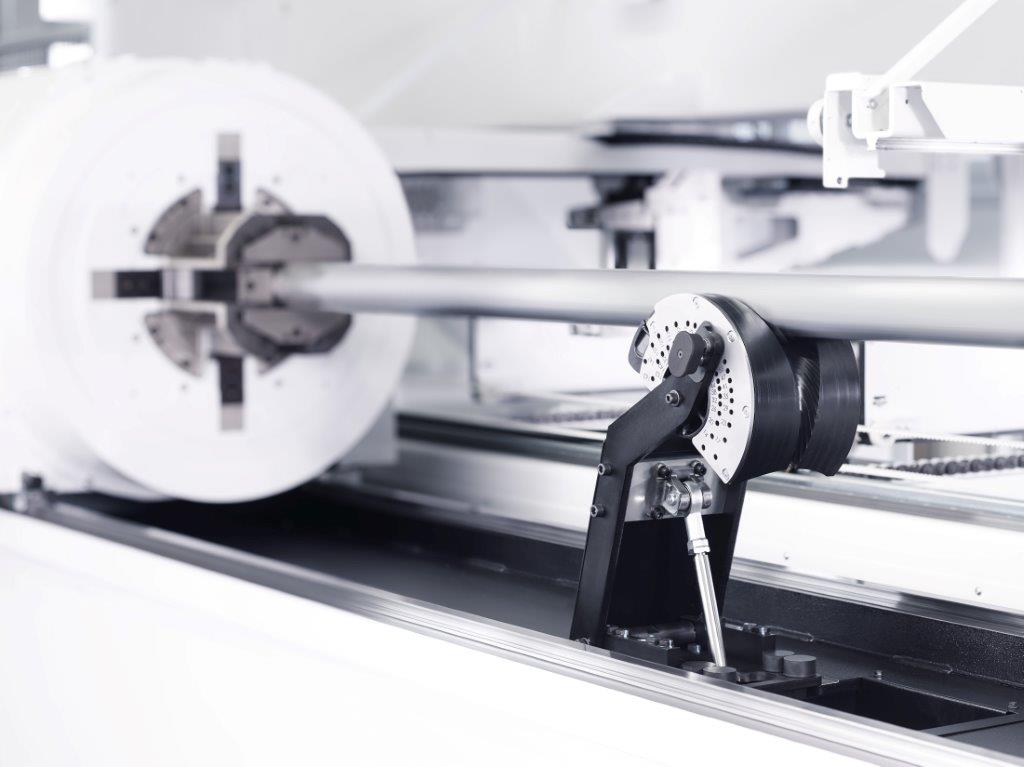

TRUMPF introduced a new laser tube cutting machine, the TruLaser Tube 3000 fiber, a cost-effective choice even at low to medium capacity utilization. It is therefore equally suitable for companies that are entering this technology as it is for companies seeking to expand their production capacity. The machine enables the versatile processing of tubes and profiles and replaces conventional tube processing steps such as sawing, drilling and milling.

Starter kit to enter the world of tube processing

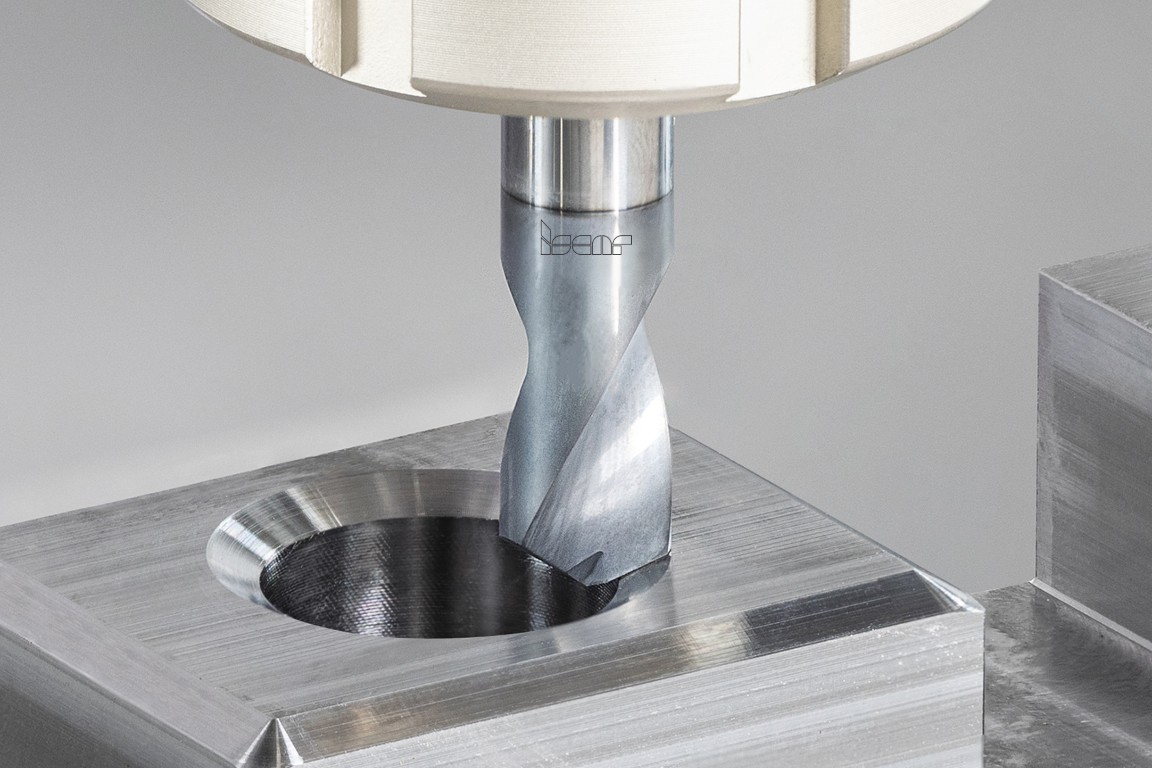

The TruLaser Tube 3000 fiber covers a broad range of applications including profiles, round tubes and flat steel bars. It also offers the option of L and U profiles. The two-kilowatt solid-state laser performs high-speed cutting of mild steel, stainless steel, aluminium and nonferrous metals such as copper and brass. An extensive set of cutting data is already stored on the machine. The TruLaser Tube 3000 fiber can cut tubes with diameters of up to 152 millimetres and profiles with an outer circumference of up to 170 millimetres. The self-centring clamping technology, which is designed to hold the tube in place and position it correctly during machining, adapts automatically to the tube dimensions without requiring manual setup by the operator. The TruLaser Tube 3000 fiber also configures other important settings automatically.

The AdjustLine function modifies cutting parameters at the touch of a button to ensure reliable cutting of lower-quality materials. SeamLine Tube detects weld seams and markings on the inner and outer surfaces of the tubes, helping operators check that the tubes are correctly aligned in the machine and that the weld seam is in the desired position in the finished part. With its easy setup and high degree of automation, the TruLaser Tube 3000 fiber is a user-friendly machine that represents a cost-effective option for small batch sizes.

Reliable and precise parts handling

The TruLaser Tube 3000 fiber cuts tubes weighing up to 18.5 kilograms per meter with material thicknesses of up to 8 millimetres. It is available in two lengths that accommodate either 6.5 or 8 meters of material. Thanks to the optional LoadMaster Tube automated loading system, the machine is also a cost-effective choice for high-volume production runs.

An integrated materials store known as the “bundle space” provides a buffer store that can hold up to 4 metric tons of raw material, or up to 5 tons with the machine version designed for an 8-meter loading length. The LoadMaster Tube system separates and measures the tubes parallel to production and transfers them to the machine. To ensure top-quality parts, step rollers support the tubes and guide them to the machining station.

These rollers can be adjusted to the current tube diameter in one simple action. The machine also features guide rollers on the unloading side which provide more support to long tubes during processing. The TruLaser Tube 3000 fiber ejects finished parts onto a rack. Set to the correct ergonomic height, this allows the operator to remove them comfortably while the machine continues working. Shorter parts can be ejected straight into a box. The TruLaser Tube 3000 fiber automatically separates cutting slugs and scrap metal from the finished parts and disposes of them in containers.

Key components easy to access at any time

Thanks to the design of the machine’s beam guard, the operator can easily access the loading and unloading sides of the machine at any time – for example to load individual tubes into the machine to process a smaller job between bigger ones. There is no need for a complete housing. A large, laser-safe viewing window makes it easy to keep an eye on the machining process.

Ready for the smart factory

Users can make changes to the machine’s production schedule or keep an eye on the machine using an app, making it even easier for the operator to keep track of the entire machining process in the TruLaser Tube 3000 fiber. A secure, OPC UA-based data interface is included to connect the machine to an ERP or MES system or to a cloud application, for example. TRUMPF machine apps provide information on program runtimes and machine capacity utilization.

For further information, please contact RETECON – Tel: (011) 976 8600.