RUSHING MACHINING WITH VERSATILE INDEXABLE MAXI-RUSH SOLID CARBIDE HEADS

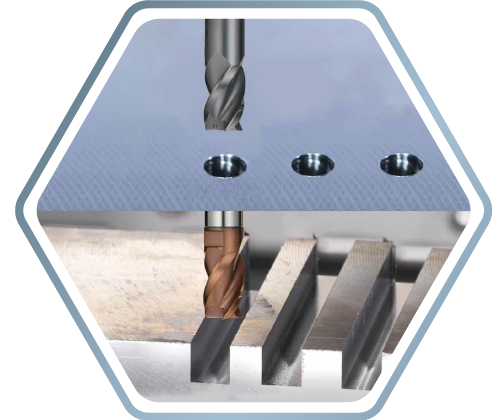

With its innovative head-indexable feature and overall outstanding advantages, the SFEED-TEC MAXI-RUSH end mill replaces most of the existing conventional solid carbide end mills in its class.

Along with its exceptional accuracy and optimum grades, the line’s quick and simple head replacement makes it a perfect solution for today’s machining needs and a superior performer that boosts productivity on a range of applications.

Along with its exceptional accuracy and optimum grades, the line’s quick and simple head replacement makes it a perfect solution for today’s machining needs and a superior performer that boosts productivity on a range of applications.

MAXI-RUSH is available in a variety of head types and shank holder lengths, such as flat, ball, corner radius, chamfer and slot, to mention a few, while providing the greatest versatility in tooling solutions.

Its rigid and precise double contact fastening system houses a flat contact surface area for precise axial runout accuracy, has a conical taper contact for self-centring and precise radial runout accuracy and is highlighted by its quick and rigid unique threading.

Its rigid and precise double contact fastening system houses a flat contact surface area for precise axial runout accuracy, has a conical taper contact for self-centring and precise radial runout accuracy and is highlighted by its quick and rigid unique threading.

TaeguTec has added oval and lens-shaped solid carbide heads that are 3D profiling capable in order to solve industry-wide disadvantages, such as excessive machining time and poor surface finish, which plague profiling operations.

The MAXI-RUSH 5-axis profile heads are designed for high-pitch, semi-finishing and finishing profiling parts used in the aerospace, power generation, medical and mould and die industries.

The MAXI-RUSH 5-axis profile heads are designed for high-pitch, semi-finishing and finishing profiling parts used in the aerospace, power generation, medical and mould and die industries.

Even in high-pitch conditions, the same surface finish can be obtained compared to solid carbide ball type end mills, making the MAXI-RUSH 5-axis profile heads capable of high-productivity machining.

Machine shops of all sizes have taken a special interest in the metalworking giant’s highly rigid MAXI-RUSH line because of its excellent machining precision, simple indexable head replacement and shorter setup time. The line now includes a wider variety of tools that are capable of handling a broad range of operations.

Machine shops of all sizes have taken a special interest in the metalworking giant’s highly rigid MAXI-RUSH line because of its excellent machining precision, simple indexable head replacement and shorter setup time. The line now includes a wider variety of tools that are capable of handling a broad range of operations.

The expanded features include a wider cutting edge contact area for improved machining stability and longer tool life, and are ideal for machining difficult-to-cut materials such as titanium alloys, Inconel, and stainless steel.

Recently, TaeguTec added the TT5513 grade to the technologically advanced MAXI-RUSH line. The ingenious grade has an ultra-fine substrate with optimum toughness features and excellent abrasion resistance. It has a nano-crystalline structured AlTiN layer, an anti-abrasion and cracking-resistant PVD-coated layer and is ideal for mould steels and pre-hardened steels.

Recently, TaeguTec added the TT5513 grade to the technologically advanced MAXI-RUSH line. The ingenious grade has an ultra-fine substrate with optimum toughness features and excellent abrasion resistance. It has a nano-crystalline structured AlTiN layer, an anti-abrasion and cracking-resistant PVD-coated layer and is ideal for mould steels and pre-hardened steels.

The MAXI-RUSH’s versatility and range are only matched by its incredible machining prowess.

A range of shapes and lengths are available, including straight shanks with necks and tapered necks made of different materials. These are available in steel, carbide and tungsten and are internal through coolant capable.

DRILLING AND MILLING CAPABLE – DRILL-MILL

TaeguTec has introduced milling and drilling capable SDM end mills and MXDM heads, which are high-efficiency machining tools designed for both, general milling and drilling operations. Their wide flute design ensures smooth chip evacuation, even at drilling depths of 1xD. Additionally, the tapered core’s reinforced rigidity and optimal helix angle ensure smooth cutting and stable machining without performance degradation during milling operations. Furthermore, this new line quickly transitions from drilling to milling at the drilling depth, improving productivity by reducing the number of machining passes.

While capable of milling immediately following drilling, drilling is possible at feed rates comparable to standard drills. Other features include excellent performance on general carbon steel, alloy steel as well as stainless steel, optimized flute design for smooth chip evacuation during drilling, tapered core with reinforced rigidity, suited to various milling operations and unequal helix angle design for smooth and stable cutting performance. Add to this helix-type internal coolant for excellent chip evacuation but solid end mill type only.

While capable of milling immediately following drilling, drilling is possible at feed rates comparable to standard drills. Other features include excellent performance on general carbon steel, alloy steel as well as stainless steel, optimized flute design for smooth chip evacuation during drilling, tapered core with reinforced rigidity, suited to various milling operations and unequal helix angle design for smooth and stable cutting performance. Add to this helix-type internal coolant for excellent chip evacuation but solid end mill type only.

For more information please contact TaeguTec – Tel: 011 362-1500.