ADVANTAGES OF MULTI-TASKING

By Paul Savides, Managing Director, PBS Machine Tools

Unless you add value to your product, simply don’t touch it!

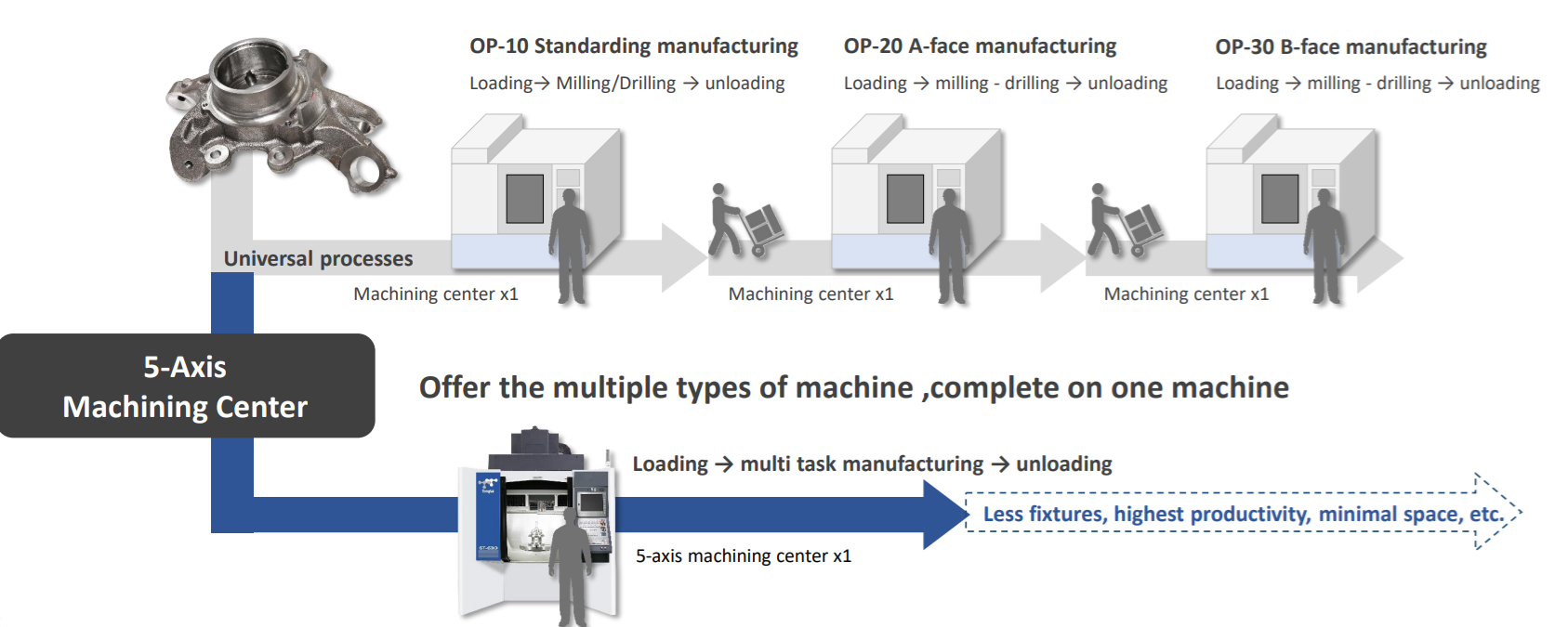

Once production is performed by multi-tasking machines, manufacturing results in the consolidation of processes.

Advantages of multi-task machine manufacturing

- Space

A multi-tasking machine uses minimal floor space, reduces operator fatigue and increases machine utilization in the production line.

- Quality

Reducing the number of operations, increases stability and improves accuracy and SPC in the process.

- Management

Less fixturing eliminates unnecessary management, time and costs. Multi-tasking is the integration of different processes in a single machine.

Multi-Task Turn-Milling Manufacturing Example

Multi-Task Knuckle Manufacturing Example

The future of manufacturing will be High Variety, Flexible – Multi Tasking with Mill + Turn Processing.

The demand for High Mix Low Volume (HMLV) processing is rising, meaning manufacturing costs will increase. Our TMS series easily masters these challenges at an affordable price performance ratio.

This new universal lathe features

- A perfect combination of lathe and milling machine for full flexibility

- Increased productivity and simple automation capabilities

- Simple, intuitive operation and conversation-guided technology cycles

- Easy planning of production due to complete machining of workpieces

- Short delivery times for standard machines

- Fast service times from a global service network and team of experts

This robust machine concept means good machine availability with high repeatability.

Digital Twin

The added value of Digital Twin makes it easier to validate the processes. Tongtai offer digital twin on all their machines to enable process simulation that validates the NC program before actual production. This ensures safety and accuracy.

For more information please contact PBS Machine Tools – Tel: 011 914-3360