By Donovan Hoole, Sales Engineer, Amada

Amada believes that quality work begins with quality tools designed and built from the ground up to deliver outstanding performance, time after time. Every feature, function and configuration we offer has been developed to address the needs of our customers. We understand productivity is the heart of your business, and we can help you optimize it in multiple ways. The Amada Group is one of the leading international machine tool manufacturers who offer solutions to the steel industry.

No two manufacturing needs are exactly alike. Finding the right solution means thoroughly understanding your objectives and configuring a solution to match them. Amada brings decades of industry experience to help you achieve your specified goals with a process that fits and enhances your workflow.

Through many years of research and development, Amada is able to supply bandsaw machinery and blades meeting all requirements. This includes the HK series (for mitre cutting), the H series (semi-automatic), HA / HFA (fully automatic) and the VM (vertical series). The latest technology now offers models such as the PC Saw (pulse cutting) CMB high speed circular saws and the VT Series (vertical mitre cutting).

Some features of these band saw machines include out of square cutting detection, motion detectors to monitor the blade for jamming or breakage while cutting, quick approach arms, no work limit switches and work lights to assist quick set up of work pieces, hydraulic blade tensioning, variable blade speed control, vice pressure control units, positively driven wire brushes, 9 times feed – for cutting long lengths and cut off counters to ensure the correct number of cuts. By using these features, semi-skilled workers can operate these machines, while certain models can be left to run unmanned on larger batch runs, thus reducing the need for dedicated machinists. Take-up conveyors and tri-pod stands are supplied in order to make material handling simple during the loading and cutting process.

These features ensure cutting accuracies of up to 0,2mm, subsequently reducing or even eliminating secondary machining processes in most cases. This in turn lowers processing time of componentry, while ultimately bringing down costs.

HPSAW – “HYPERSAW” HIGH-PERFORMANCE CNC BAND SAW

Extremely powerful band saw for section lengths up to 600mm

In pursuit of the fastest cutting performance possible, Amada has developed the HP Saw in conjunction with the “Axela – HP blade.

The HP bandsaw defies the norms of bandsaw cutting with its patented bridge type saw head frame and many other un-imaginable features. This energy saving technology is operated through a WINDOWS based CNC controller with all the pre-set cutting data stored and easily accessible for efficient operation without relying on the operator for optimal production cutting.

The HP Saw is the first of its kind to employ a “zero degree” blade twist. This means that the drive and driven wheels are both mounted perpendicular to the frame. By having zero twist in the blade, fatigue is eliminated from the blade body during operation. This, together with the automatically adjusted dual wire brush system and high pressure coolant application, ensure that blade life and production are maximized. Anti-vibration rollers eliminate vibrations caused by high speed processing, and the AC servo vice ensures fast, accurate material positioning, while up to 1 ton of material weight can be accommodated.

CM 75 DG Powerful Carbide Circular Saw

Amada circular sawing machines significantly reduce cycle time during high-precision cutting of steel billets. By using a carbide-tipped circular blade, instead of a linear blade, high speed revolutions are achievable thus facilitating high speed and high accuracy cutting on smaller diameters. The built-in Dyna Guide suppresses blade vibration and ultimately a skew cut.

With the automatic loading table continuous cutting operation is achievable, while the CNC control promotes ease of operation and the use of optimum pre-set cutting conditions.

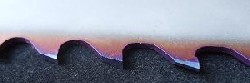

BANDSAW BLADES

A full range of bandsaw (Bi-Metal) blades are produced by Amada to compliment machine technology. A bandsaw demonstrates the ability and limitations of a blade, meaning that a machine is only as good as the blade being used.

Amada SGB – high productionM-42 bi-metal for metal cutting band saw.

Amada XCELA G Series – high-performance carbide tipped blade for metal cutting band saw.

Amada blades have earned the reputation of extreme reliability and longevity. Manufactured in Japan to the most stringent quality standards and utilising the latest in Electron Beam Welding methods, Amada blades have become the benchmark of the industry. These strict manufacturing measures ensure that premature blade breakage is almost unheard of in the Amada range. The comprehensive variety of blades offered is designed to cater for all types of cutting conditions on all different types of steels and profiles.

CIRCULAR SAW BLADES

Manufactured from the highest quality carbide grades, Amada circular saw blades are guaranteed to offer unmatched accuracy and consistency.

Continuous, accurate cuts are achieved along with outstanding longevity thanks to state of the art manufacturing processes and post manufacturing testing.

Through the dedicated backup of Amada, the robustness of their machinery, the longevity of their blades and the reputation built over many years, Peace of Mind is the most important part of owning an Amada.

For more information, please contact Amada – Tel: 011 453-5459.

Visit AMADA