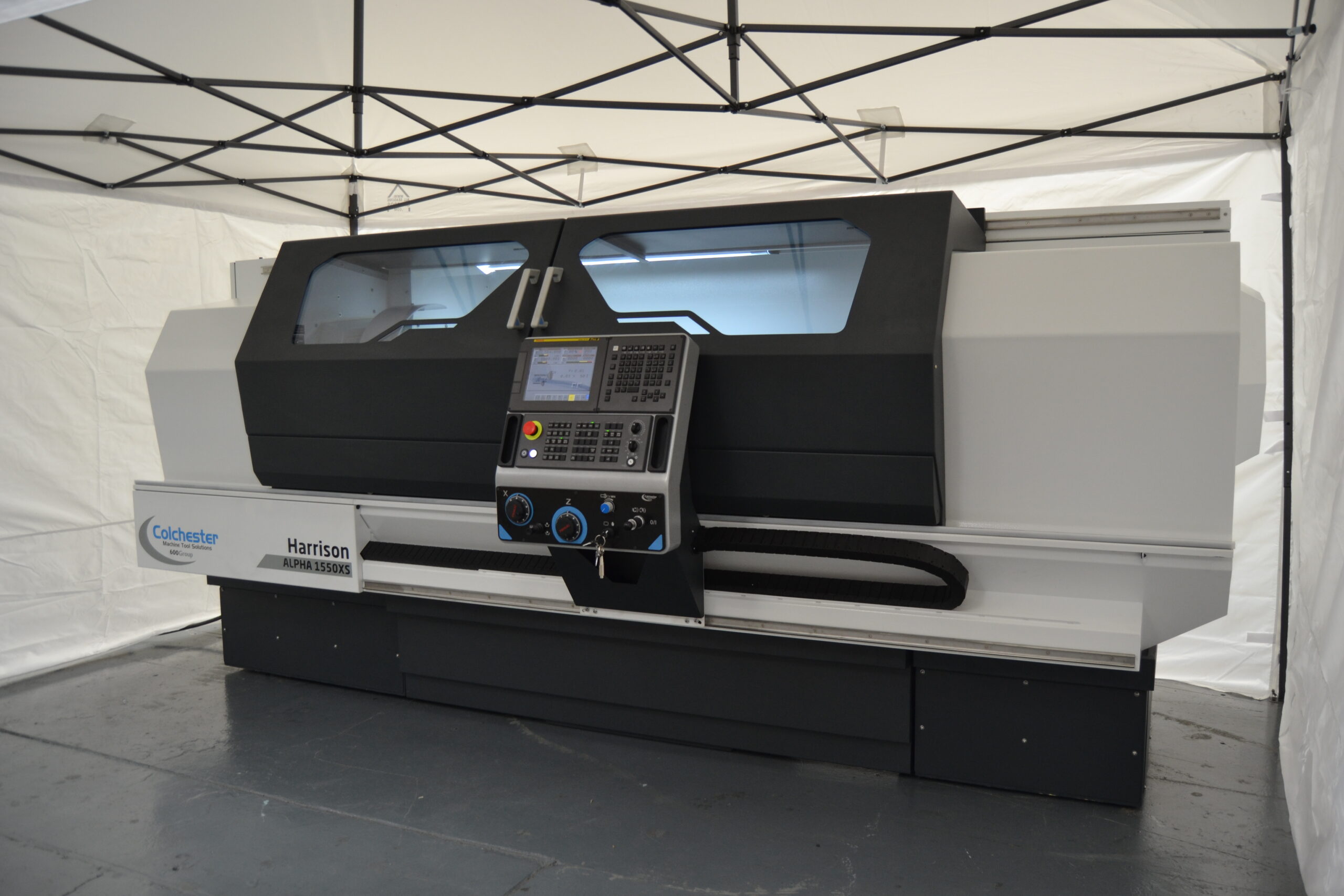

ALPHA X SERIES – THE WORLD’S FINEST CNC COMBINATION LATHES

All Alpha X Series lathes are perfectly suited to producing detailed and intricate one-offs to the highest standard of finish and accuracy. With their advanced Fanuc control and software systems, they are ideal for turning small-to medium sized batches with fast, high quality repeatability, excellent accuracy and surface finish and, most importantly of all, lower component production costs.

Alpha quality, plus a wide range of training options, has made Alpha lathes the favourite choice for industry, colleges and training centres around the world. Ideal training features include compatibility with industry standard ISO programs and Colchester’s AlphaLink software which enables multi-desk training to be given.

Machine Bed

Colchester Machine Tool Solutions’ cutting-edge lathe design and construction quality begins with the machine bed. Alpha beds use high performance cast iron, with a unique ‘Warren’ type construction for maximum strength and optimum swarf clearance.

In addition, all Alpha lathe beds are mounted on cast-iron plinths to neutralise stress in the machine bed and slideways are hardened and specially ground to ensure high-precision, parallel operation of the lathe at all times.

Operators Console

The operator’s console is located, for optimum operator convenience and efficiency, directly in line-of-sight with the cutting tool. The hand wheels are installed at the ideal ergonomic height for ease of use and have the Alpha’s popular “one-click-one-micron” rotational feel sensitivity.

The complete operator’s control panel moves on its own independent carriage which allows it to be moved quickly and effortlessly aside during loading and setting up.

Drive Train

Into the design and development of all Alpha lathes goes the technical expertise of specialists from Colchester Machine Tool Solutions’ partner company Pratt Burnerd chucking systems. Their combined research programs ensure that all new Alpha XS lathes feature the most advanced developments in spindle bearing technology and chuck design. This provides the highest possible spindle speeds and optimum chuck performance for high accuracy turning with maximum load carrying capacity.

Headstock

Crucial to turning precision and quality is the design and capability of the headstock. These lathes have top rated Fanuc spindle motors for extra power and more torque in all speed ranges. This means that ‘bottom end’ torque has been increased by over 75% giving excellent, extremely accurate metal cutting performance at lower speeds.

All Alpha XS lathes are equipped with auto gearbox change – maximising efficiency and productivity.

Alpha XS and XC Range – Fanuc 0i TF Plus Control

All Alpha XS and XC lathes are fitted with a customised Fanuc control that gives you the option of manual or automatic operation via a simple key switch. In manual mode, the control employs the latest upgraded version of Colchester Machine Tool Solutions’ own “Alpha System” which is acclaimed by thousands of Alpha users to be the simplest and most shop floor friendly teach lathe control in the world.

In automatic mode, the full strength of Fanuc’s latest technology is brought into play with the Manual Guide I programming system.

This conversational system has been completely revamped from previous generations to become an outstandingly powerful and comprehensive conversational programming system.

The combination of these two systems on one machine means that the Alpha XS is the most versatile and capable lathe ever produced. It will do virtually anything you ask of it!

The Alpha System

Specifically developed unique control software will enable users to double, triple or even quadruple productivity when compared with other turning methods.

Alpha System uses easily recognisable screen graphics along with simple question and answer prompts to guide you. It is also the reason that the Alpha System uses a touch screen, so you can work directly on screen rather than hunt for the right button to press..

Manual Turning

Turn the key and you are turning manually. It’s as simple as that! The manual screen display shows X and Z positions just like a DRO plus spindle speed, tool number and feed rate.

Even if you haven’t used a lathe since your schooldays you could walk up to an Alpha XS now and cut metal.

Semi-Automatic Turning

With the Colchester Alpha System, a wealth of semi-automatic turning operations can be performed. These include parallel turning to stop positions, chamfers and radii, tapers, threads, grooves, box cycles and even contour shapes. These can be linked consecutively to produce even the most complex of components quickly and efficiently.

What’s more, the easy to understand shop floor language coupled with touch screen simplicity means that a turner can learn to machine parts quickly.

Most operators will learn to use the Alpha System in less than half a day!

Manual Guide i for Alpha XS and XC

Automatic Turning

Manual Guide i is the latest and most powerful conversational programming system from Fanuc. It offers the most comprehensive and feature laden aid that any lathe programmer could want and becomes available on the Alpha XS when the key switch on the control panel is turned to the automatic position.

Simulation and Animation

Manual Guide I has a more powerful graphics package than many commercial CAD/CAM systems. After a programme has been created, a simulated component can be viewed in any direction, or as a 3D model that can be cut or sectioned or magnified to see detail.

This simulated component can then be animated to show the cutting process, the toolpath, metal removal and the finished component to ensure that what you get is what you have programmed and exactly what you want.

Customised Pages

Despite the enormous strength of the Manual Guide I system, engineers have been able to bring their turning experience into play to develop customised cycles especially for the needs of a manual/CNC type of lathe. These Colchester unique developed cycles will save you a considerable amount of time and button pushing.

This is the most user friendly and cost effective entry level combination lathe control in the world!

The absolute minimum of training is needed to get these machines cutting metal and making you money.

CNC Turning

The real strength of Manual Guide i is that it is effectively a CNC Graphical user interface. All the time you are working in Manual Guide i, the 0i TF is creating a CNC programme in the background. This means that conversion from conversational mode to CNC mode is instant. It also means that you can work in either CNC or conversational mode or even both at the same time. Furthermore it means that industry standard CNC programmes can be loaded into and out of the control at any time.

The Alpha XS and XC are powerful conversational lathes that can also run CNC programmes developed elsewhere or to create CNC programmes for use on other machines.

Alpha XS Range with large working envelope

The heavyweight 1660 and 1760XS models are both available in bed lengths of up to 6 metres and spindle bore up to 230mm.

The heavyweight versions – of the best-selling combination lathe in the world – are designed to exceed customer demands for turning larger diameter components efficiently and are truly class leaders in terms of overall performance.

Alpha XC NEW 3 Axis CNC Combination Lathes

The Alpha XC introduces full milling, drilling and tapping functions to the Alpha range, fully harnessing the Fanuc Oi-TF control combined with the Manual Guide i conversational programming system to reduce the need for second machine load and operation production – specifically for one-off components and small batch production.

The Alpha XC 3-axis CNC combination lathe is identical in functionality to the Alpha XS range of machines, but now has the addition of a fully interpolating c-axis, while still retaining the operational simplicity that makes the Alpha range the leading choice worldwide.

The manual / CNC lathe is mounted with a newly developed headstock, allowing programmed selection of the c–axis drive, allowing milling / drilling cycles to be achieved with the use of driven tooling.

To allow for these extra lathe operations, full c-axis cycles are available through the Manual Guide i conversational programming system.

For more information, contact 600 SA Machine Tools – Cell: 072 157 6003.