ACHIEVE EXCELLENCE IN MANUFACTURING WITH CUTTING-EDGE TECHNOLOGY

Elevate Your Manufacturing Game with TaeguTec

In the competitive landscape of South African manufacturing, efficiency and cost-effectiveness are paramount, and the manufacturing sector in South Africa is diverse and dynamic, encompassing industries, such as automotive, aerospace mining and heavy machinery. These industries are pivotal to the country’s economic growth, providing employment opportunities and contributing significantly to the GDP. However, they face challenges such as rising operational costs, the need for technological advancements and global competition.

To thrive in this environment, South African manufacturers must adopt innovative solutions that enhance productivity and reduce costs. TaeguTec’s cutting-edge solutions include the SOLID-3-DRILL, DRILL-SFEED, RHINO-TURN, SFEED-BARREL, CHASE-8-SFEED and WIN-MILL lines.

These innovative tools are designed to revolutionize machining processes, offering unparalleled benefits that can significantly enhance productivity and reduce operational costs.

SOLID-3-DRILL – Precision and Performance

The SOLID-3-DRILL is a game-changer for industries, requiring high-precision drilling. Its higher number of teeth increases productivity, while its unique three-flute design ensures superior chip evacuation, reducing cycle times and enhancing hole quality.

This drill is particularly beneficial for industries, such as automotive and aerospace, where precision is non-negotiable, as well as for companies that demand excellent performance in steel and cast iron machining. By minimizing tool wear and maximizing cutting efficiency, the SOLID-3-DRILL helps manufacturers achieve higher throughput and lower per-unit costs.

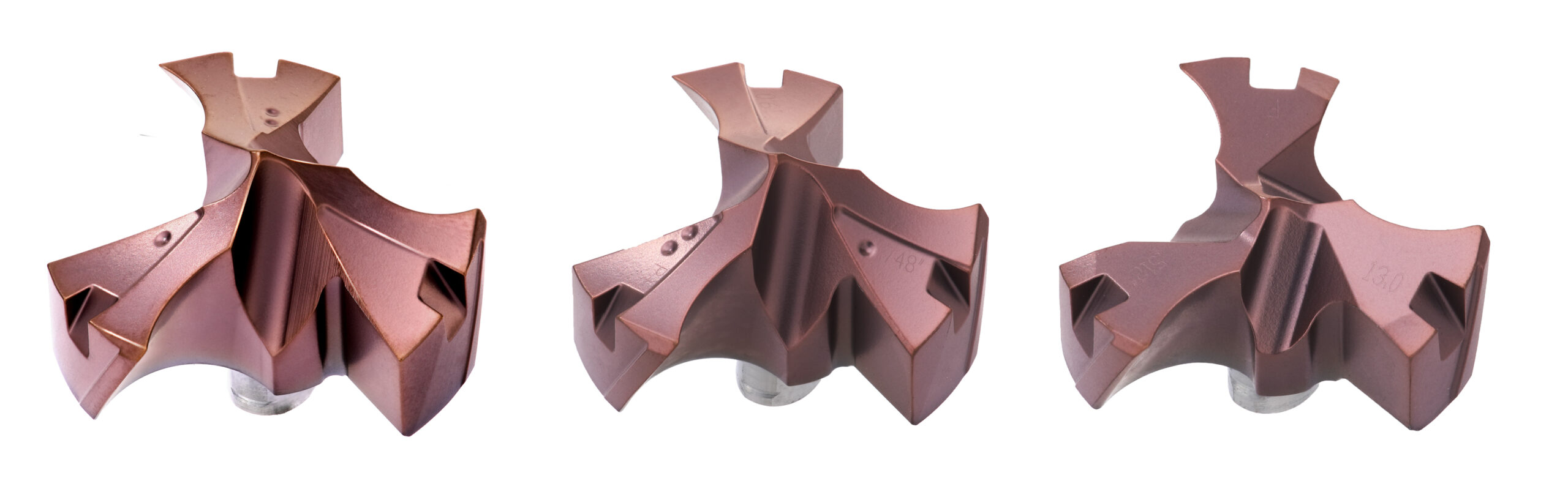

DRILL-SFEED – Speed Meets Efficiency, 3-Flute Indexable Drill

For industries looking to boost their drilling speed without compromising on quality, the DRILL-SFEED is the ideal solution. This high-feed drill is engineered to operate at higher speeds and feeds, significantly reducing machining time. Its robust design, strong cutting edges and latest coating technology combine stability, longevity and high productivity, making it a cost-effective choice for high-volume production environments.

By reducing cycle times and increasing tool life, the DRILL-SFEED enables manufacturers to meet tight deadlines and reduce overall production costs. Its original clamping structure allows for the simple replacement of drill heads, as well as varying sizes of heads onto a single tool body, thus facilitating economical end-user drill stock management.

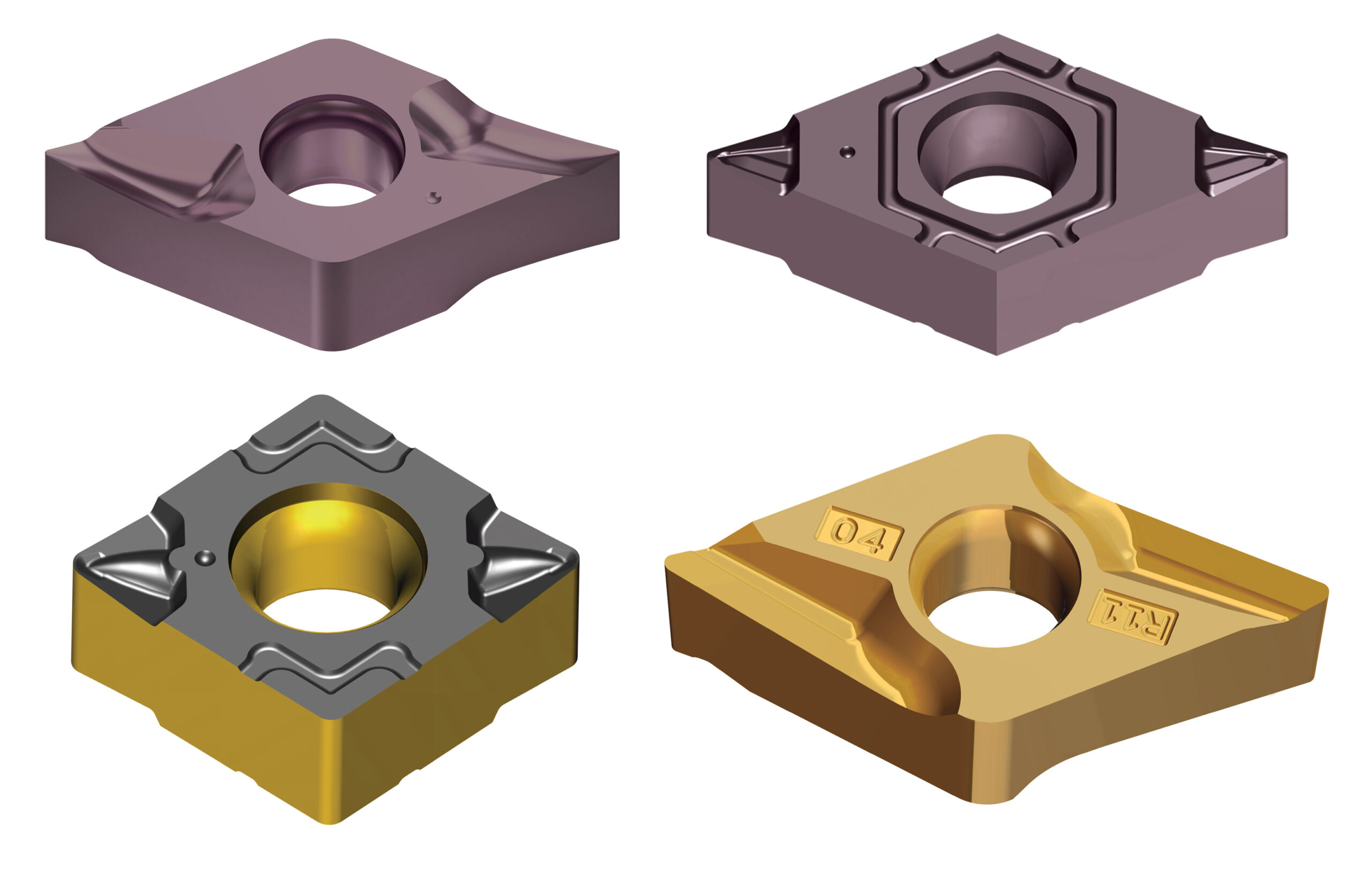

RHINO-TURN – Versatility and Durability, Small but Strong

Turning operations are a critical aspect of many manufacturing processes and the RHINO-TURN line offers unmatched versatility and durability. Designed to handle a wide range of materials, from steel to exotic alloys, RHINO-TURN tools provide consistent performance and extended tool life.

This versatility reduces the need for frequent tool changes, thereby minimizing downtime and increasing productivity. Additionally, the enhanced durability of RHINO-TURN tools translates to lower replacement costs, further driving down operational expenses.

SFEED-BARREL – Innovation in Milling

The SFEED-BARREL line represents the pinnacle of innovation in milling technology. Its unique barrel-shaped design allows for larger step-over distances, reducing the number of passes required to achieve the desired surface finish. This not only speeds up the milling process and reduces machining time, but also improves surface quality.

The SFEED-BARREL is particularly advantageous for industries, such as mould and die, where surface finish and dimensional accuracy are critical. By optimizing milling operations, this tool helps manufacturers achieve higher productivity and lower costs.

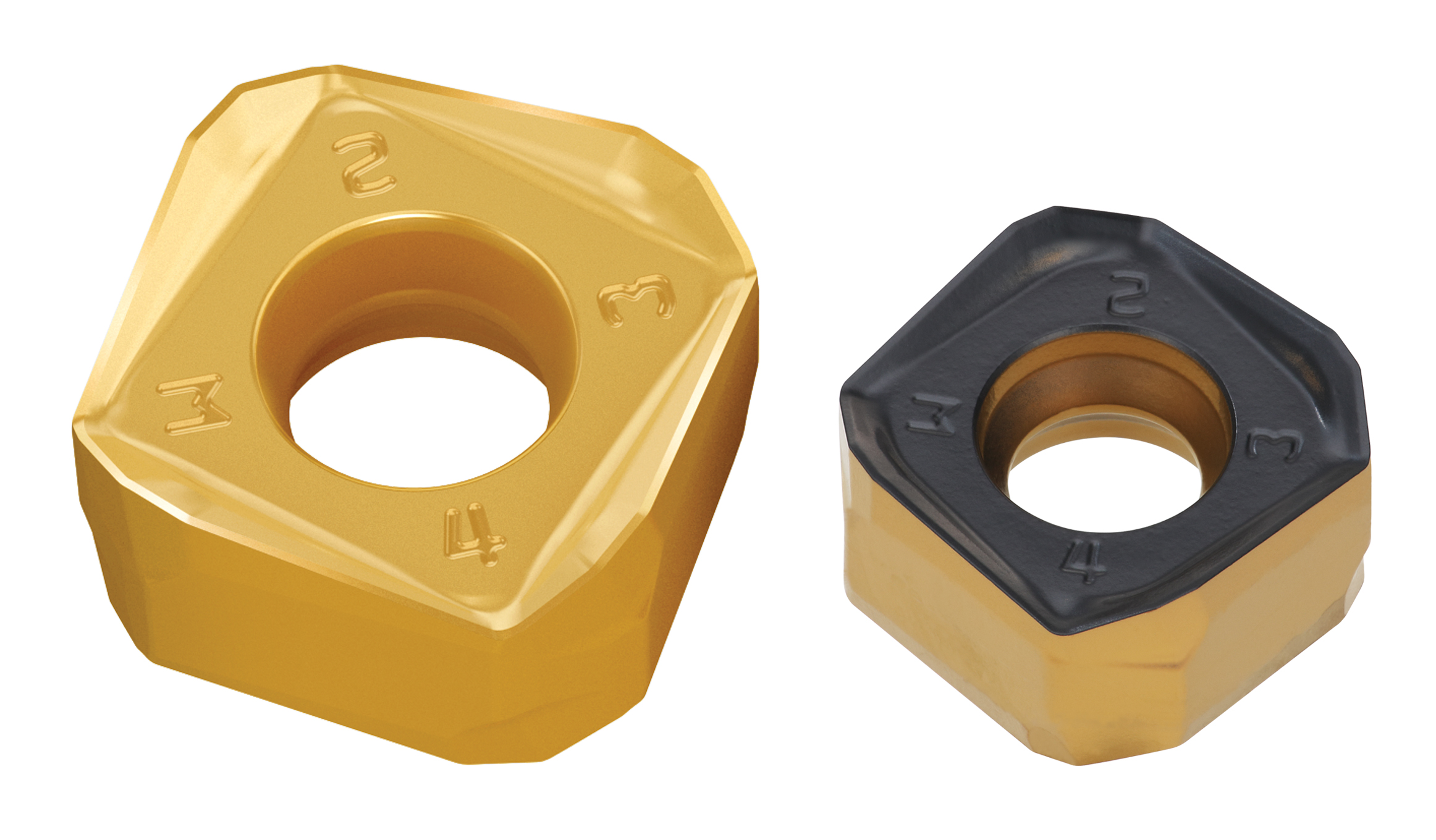

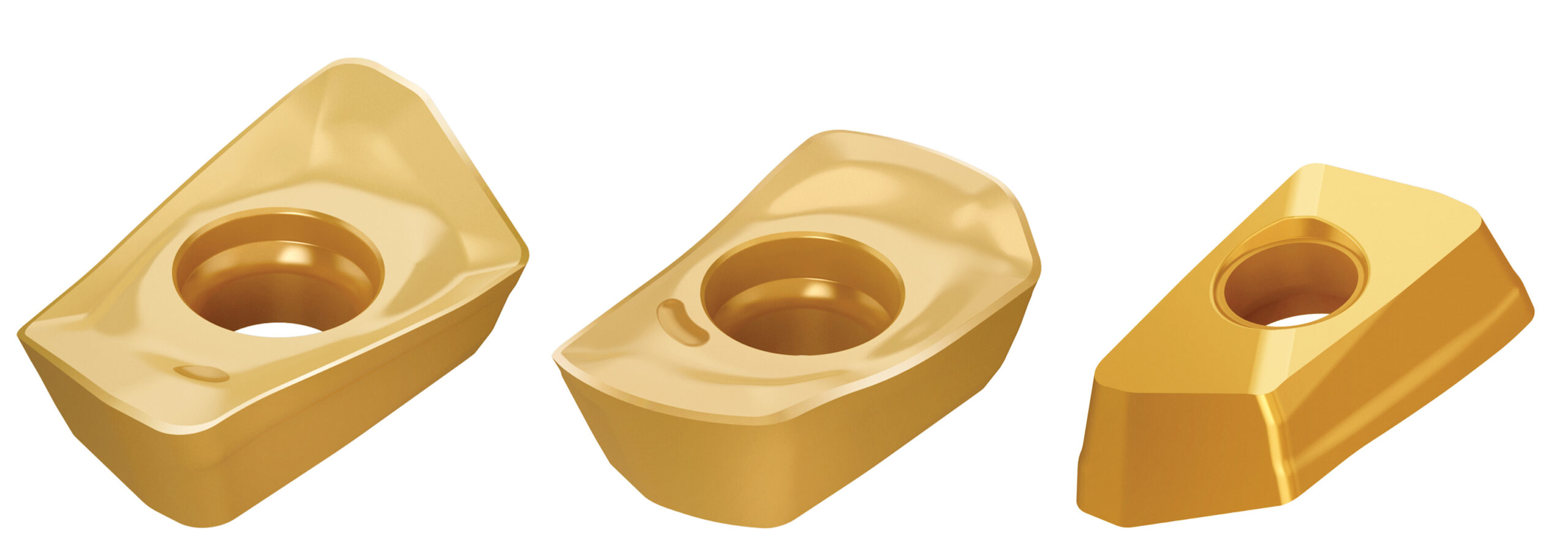

CHASE-8-SFEED – High-Feed Milling Excellence

The CHASE-8-SFEED line is designed for high-feed milling applications, offering exceptional performance in roughing operations. Its innovative geometry allows for higher feed rates, reducing machining time and increasing productivity.

The robust construction of CHASE-8-SFEED tools ensures long tool life, making them a cost-effective choice for demanding milling tasks. By enhancing material removal rates and minimizing downtime, CHASE-8-SFEED tools help manufacturers achieve significant cost savings.

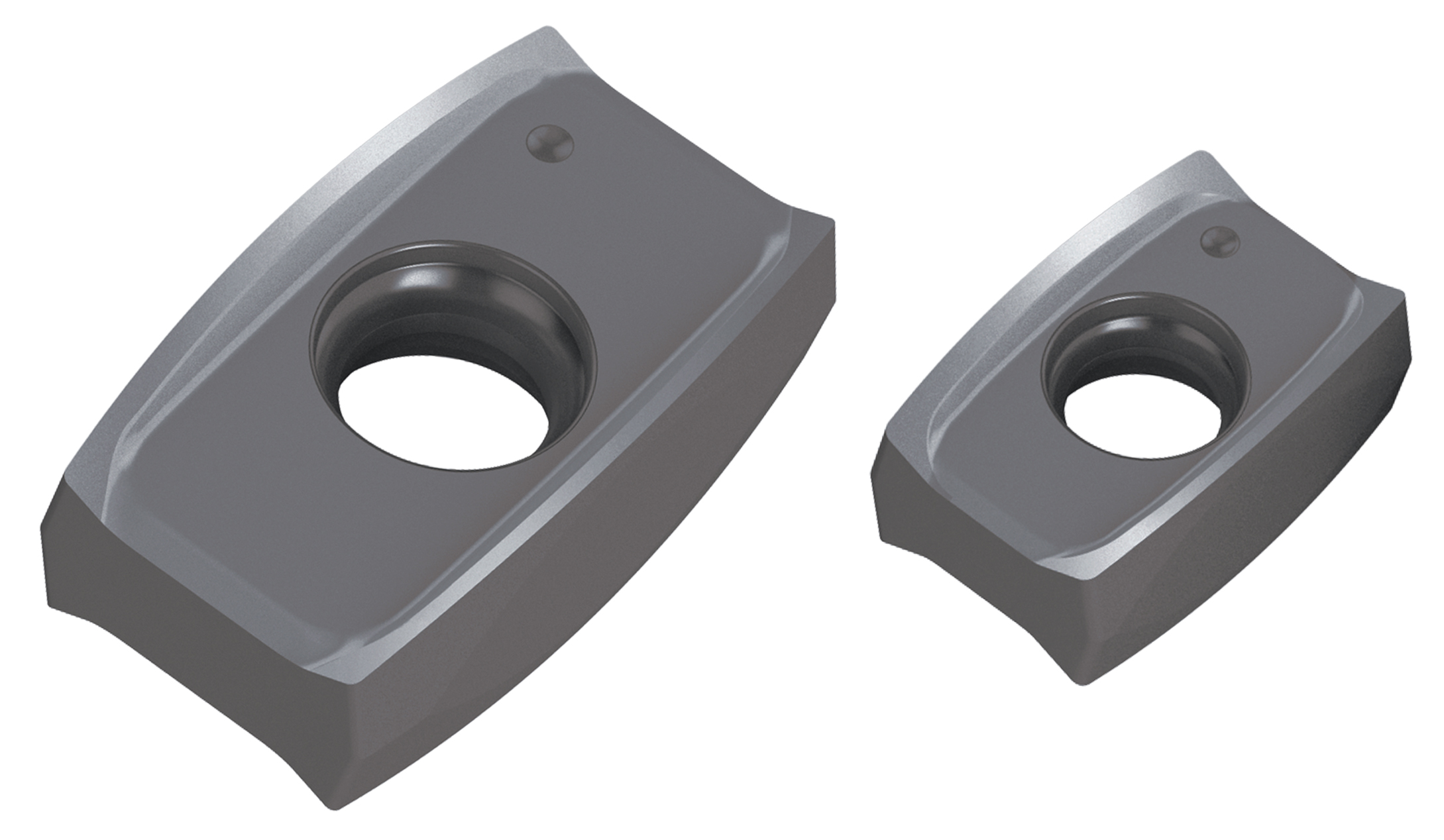

WIN-MILL – Precision and Flexibility

WIN-MILL tools are engineered for precision milling applications, providing excellent surface finish and dimensional accuracy. Their versatile design and V-bottom for rigid clamping allow for use in a wide range of materials, making them ideal for industries, such as mould and die, aerospace and automotive.

The high-performance capabilities of WIN-MILL tools reduce the need for secondary operations, thereby increasing productivity and reducing overall production costs.

TaeguTec Advanced Edge

The SFEED-TEC and WIN-SFEED family of cutting tools offer advanced solutions for various machining applications. SFEED-TEC tools are designed for high-speed and high-feed operations, providing superior performance and extended tool life. WIN-SFEED tools, on the other hand, are optimized for stability and precision, ensuring consistent results in demanding environments. Both lines contribute to increased productivity and reduced operational costs, making them valuable assets for South African industries.

TaeguTec’s SOLID-3-DRILL, DRILL-SFEED, RHINO-TURN, SFEED-BARREL, CHASE-8-SFEED, WIN-MILL, SFEED-TEC and WIN-SFEED lines offer South African industries a competitive edge. These cutting tools are meticulously designed to enhance productivity, reduce cycle times and lower operational costs. By integrating TaeguTec’s innovative solutions into their manufacturing processes, South African manufacturers can achieve greater efficiency and profitability, positioning themselves for success in the global market.

For more information please contact TaeguTec – Tel: 011 362-1500.