Continually improving our customers’ experience after sale and delivery of our CNC’s is very important to PBS Machine Tools.

By Paul Savides, Managing Director, PBS Machine Tools

How do we do it?

Simply, together with our suppliers; we create and test various advanced technologies that have been developed in order to assist our customers to improve their existing manufacturing impediments. Thus, optimizing their OEE and resulting in increased output and higher profit.

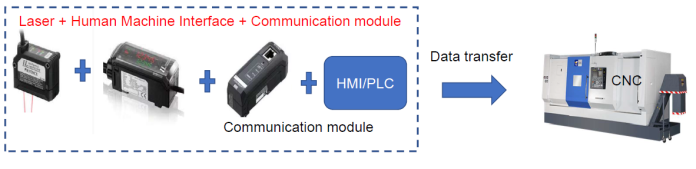

Leaning on previous Digital Transformational Control Systems, we have, in one instance, been able to adapt, replicate and evaluate alternative solutions, capable of addressing out of balance material deviations, predominantly experienced in castings and forged components.

Understanding the design and effective, operational capability of our CNC, we were able to adopt and test two solutions that can enhance machine and manufacturing process productivity, including

Pre and post component measuring through:

- External, in-process measuring to pre-qualify the part

- In machine measuring to asses and select the optimum machining program per situation

- Post machining measuring to confirm machining conformity

Adaptive Cutting Condition Control by:

- Monitoring the Axis load

- Automatically adjusting the feed rate

- Ensuring stable, efficient machining conditions

Through these guidelines our system can:

- Automatically reject unbalanced out of gauge workpieces

- Select appropriate machining programs

- Adjust the feed rate in response to load variations

Ultimately, we can improve OEE through:

- Achieving more stable machining outcomes

- Better machine efficiency

- Improved tool usage criteria

- Saving significant input costs

In-process QC allows the user to make operational changes that occur during the machining process, resulting in higher quality, which in turn produces a higher Return on Investment (ROI) as a result of fewer production failures and defects, which simultaneously lowers manufacturing costs.

Also, when using Tongtai designed Edge Computing (TiMS), and/or Line Management (TLM) software, the gains experienced will exceed the increased cost expenditure of other defect prevention methods and once again, the benefit being an increase in profitability.

For more information please contact PBS Machine Tools – Tel: 011 914-3360.