UPGRADED AUTOMATION SYSTEM MAKES MX-100 FASTER AND MORE ACCURATE

In today’s manufacturing industry, there is a growing need for high-precision production within tight deadlines. However, there are problems, such as the challenge to find highly skilled and experienced operators. Additionally, for the installation of automation equipment, such as a gantry loader or robot, extra floor space is required.

To solve these problems, Nakamura-Tome introduced the ‘Compact Loader servo’ as a gantry replacement, offering a built-in automation solution for the MX-100 machines.

What is Compact Loader servo?

The Compact Loader servo is a built-in automation system that is mounted on the MX-100 and performs loading and unloading.

The following points have been extended from the conventional Compact Loader:

- Servo motors on all axes

- Enhanced positioning accuracy

- Increased number of the teaching point setting

- Faster travel speed

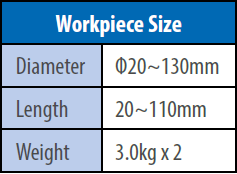

The Compact Loader servo has two grippers, and the maximum transport weight for each hand is 3.0 kg in case of 2-piece operation. Workpiece size ranges from 20 mm to 130 mm in diameter and 20 mm to 110 mm in length.

The Compact Loader servo has two grippers, and the maximum transport weight for each hand is 3.0 kg in case of 2-piece operation. Workpiece size ranges from 20 mm to 130 mm in diameter and 20 mm to 110 mm in length.

Benefits of Compact Loader servo:

Compact Layout with minimum Ceiling Height Limitation

As its name suggests, the Compact Loader servo is specially designed to save space. This means that even after being mounted on the MX-100, the height of the machine remains the same, allowing for easy installation even in factories with limited ceiling heights. Unmanned operation is achievable by using the Compact Loader servo and additional automation equipment as described below.

- Example 1: Compact Loader servo + Bar Feeder

The Compact Loader servo and a bar feeder can be used together. The bar feeder supplies a blank bar material, while the Compact Loader servo unloads bar remnants or finished parts, serving as a parts catcher.

- Example 2: Compact Loader servo + Work Stocker

By operating the Compact Loader servo and a work stocker such as HAKO-BEI together, finished parts can be stored even during night-time operation without an operator.

Incorporating the Compact Loader servo with other automation equipment can extend automated operations further while minimizing the additional space required.

Enhanced Positioning Accuracy with Servo Motors on All Axes

The newly developed Compact Loader servo is incorporated with servo motors on all axes, including the vertical axis handle, ensuring a higher positioning accuracy of ±0.1 mm.

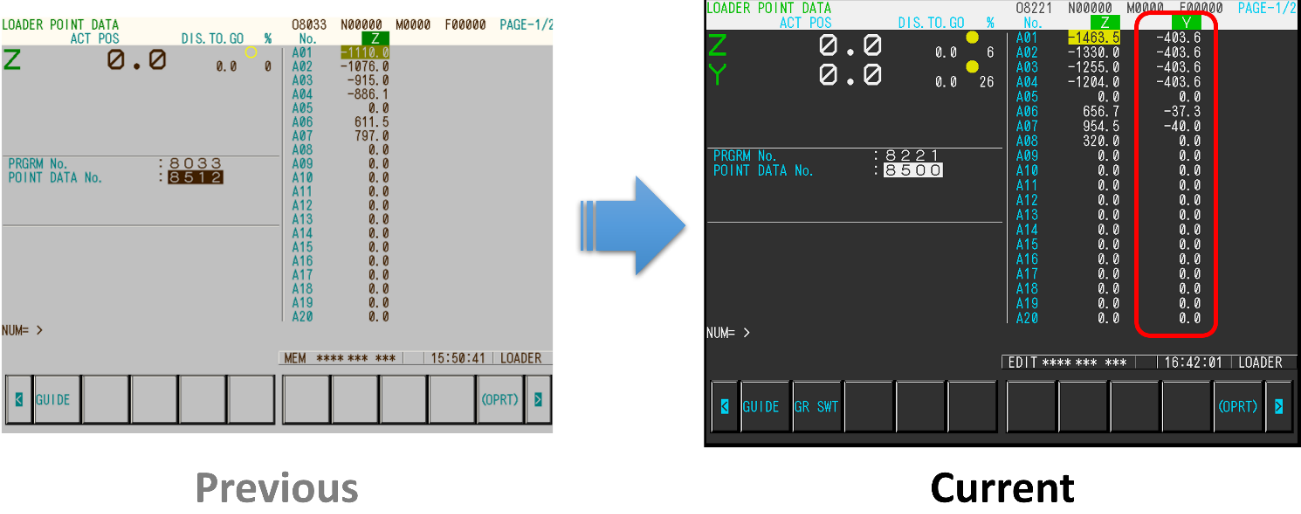

Installing servo motors on all axes allows users to specify teaching points. Up to 40 teaching points can be set for a workpiece. Moreover, teaching points for up to 500 pieces can be stored as fixed form.

Installing servo motors on all axes allows users to specify teaching points. Up to 40 teaching points can be set for a workpiece. Moreover, teaching points for up to 500 pieces can be stored as fixed form.

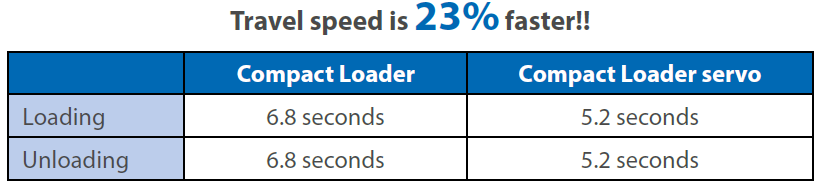

Reduce Cycle Time with Faster Loading and Unloading

The servo motors on all axes enable the quick loading of blank materials and unloading of finished parts while maintaining precise positioning, achieving a 23% speed boost in loading/unloading.

Easy and Fast Operation for Anyone

You can operate the Compact Loader servo with the NT SmartX. Simply switch the Y-axis setting of the Compact Loader servo from “Parameter setting” to “Point setting.” No need to install new software or input complicated programs.

Finally, the Compact Loader servo offers valuable insights for customers considering automated operations with the MX-100. Movements and features can be observed in the following video.

Finally, the Compact Loader servo offers valuable insights for customers considering automated operations with the MX-100. Movements and features can be observed in the following video.

Change from “Parameter setting” Compact Loader Y-axis

For More information, contact WD Hearn – Tel: 021 534 5351.