BETTER SURFACES THANKS TO NEW INTERNAL COOLANT

Walter launches M5460 profile milling cutter

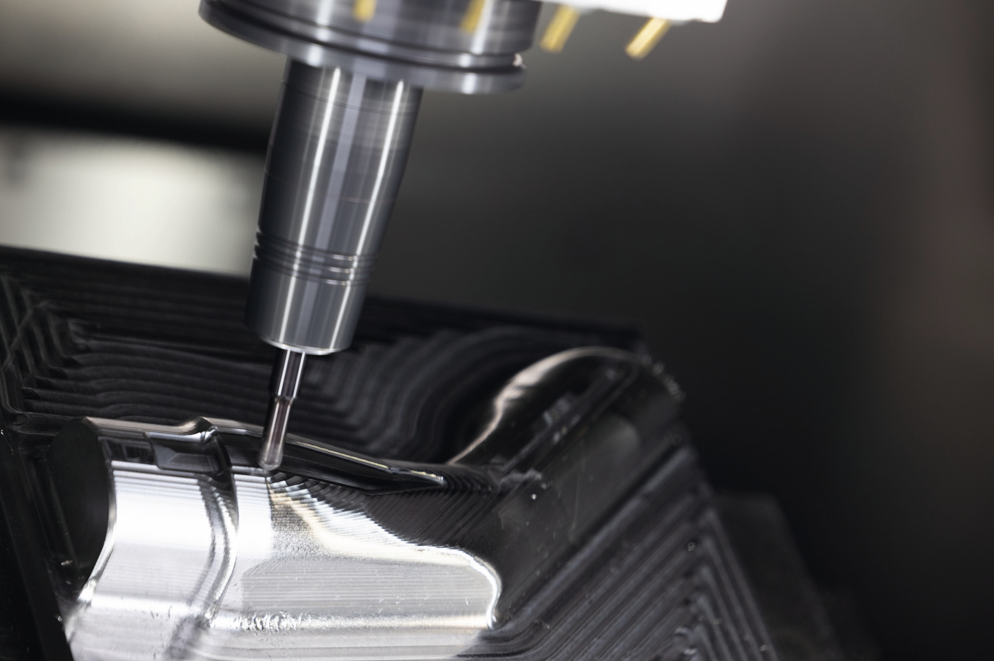

Walter is presenting a new profile milling cutter of the Xtra·tec® XT generation in the form of the M5460. The milling cutter (dia. 8–32 mm or ⅜–1″) has an internal coolant supply which can be used with compressed air MQL (minimum quantity lubrication) or emulsion depending on the material and application. This optimises chip removal and therefore surface quality and process reliability. The Xtra·tec® XT milling cutter, designed for finishing, semi-finishing and hard milling, is suitable for profile milling of complex freeform surfaces, for example those on blisks, as well as for deep cavities in steel, stainless steels, cast iron, materials with difficult cutting properties and for hard machining up to 63 HRC. The double-edged, precision-ground indexable inserts combine proven geometries with Walter’s universal, wear-resistant cutting tool materials for ISO P, K, M and S and with the WHH15X high-performance grade for machining ISO H.

Walter offers the profile milling cutter in five different interface versions: With cylindrical shank (steel and solid carbide), Weldon, ScrewFit and cylindrical modular. The M5460 can be used universally owing to these options and also due to the wide variety of cutting tool materials, for example in general mechanical engineering, the aviation or energy industries. Since the cylindrical modular interface is mainly used in the mould and die making industry, users are given a “plug & play solution” for this. Other benefits include the higher cutting speeds that are possible and less rework due to the improved surface quality.

For more information, please contact Spectra Carbide Tooling Technology – Tel: 021 555 4144.

WALTER ROUNDS OFF ITS RANGE OF SOLID CARBIDE UNIVERSAL MILLING CUTTERS

Xill·tec® – Powerful milling in a plug & play solution

With the Xill·tec® MC230 and MC233 Advance milling cutters, Walter already introduced two ranges of solid carbide milling cutters that are powerful and can be used universally – for all ISO materials from groups P, M, K, N and S, as well as for all standard roughing and finishing applications and milling strategies. As part of a second launch stage, the tool manufacturer is now rounding off its range with Xill·tec® two-edge and eight-edge milling cutters, offering diameters of between 2 mm and 25 mm and cutting lengths from 1 to 5 × Dc. With these long cutting lengths, Walter is embracing the trend for dynamic milling as a standard application in the universal range. One of its major advantages is that the entire tool length can be used with high material removal rates. There are also various geometries, each developed for a particular application, material or machining strategy.

The Xill·tec® MC230 Advance basic range also sees the addition of new Xill·tec® milling cutters from the MC233 Advance range. These are designed with chip breakers and are therefore suitable for high chip volumes, such as for dynamic roughing. In other words, they are suitable for applications where the chips need to be kept short, despite using long cutting edges and safely carried away. When compared to competitors, both milling cutters have a tool life that is around 30% longer when used at the same cutting speed and with the same material. This is thanks to geometries whose variable helices are coordinated with the number of teeth and cutting edge length, combined with the new tough WK40TF universal grade with TiAlN coating. The latter was developed and manufactured by Walter for Xill·tec® solid carbide milling tools.

For more information, please contact Spectra Carbide Tooling Technology – Tel: 021 555 4144.