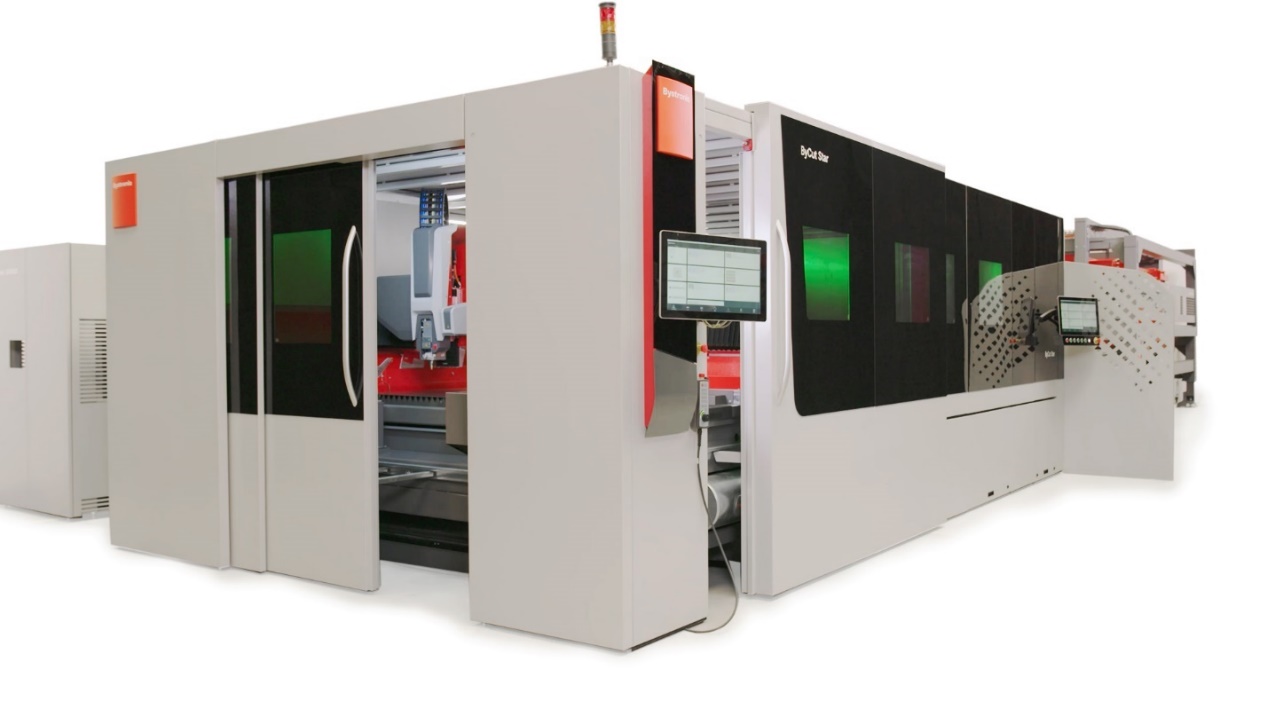

Impressive high cutting speed, intelligent cutting process and a new design – this is how the new ByCut Star presents itself. With 30 kilowatts and an optimized cutting process, it now cuts steel, aluminium, stainless steel, brass and copper precisely and reliably for even more quality.

Higher cutting quality and productivity is provided thanks to more laser power and smart features. Bystronic has advanced into a new dimension of fiber laser cutting, the ByCut Star with impressive 30 kilowatts of laser power. The high-end fiber laser stands for high-precision Bystronic technology, a stable cutting process up to the highest laser powers and for a wide range of applications.

However, sheet metal workers not only need a lot of laser power, but also intelligence, reliability and sustainability; this combination makes the laser cutting process really satisfying and successful.

Thus, at Bystronic, customer success is built on a concept of three pillars, namely Power, Intelligence and Cutting Process Improvement, including MixGas technology.

Smart features, such as the “Intelligent Cutting Process (ICP)”, the “Nozzle Control Tool (NCT) with KerfScan” or the “Parameter Wizard” optimize the entire cutting process, while ensuring that it stays on track. Users enjoy optimum capacity utilization and remarkable production uptime.

30 kilowatt of laser power

The technological leap from the previously available 3- to 20-kilowatt levels to the new 30-kilowatt level is considerable and opens new possibilities for Bystronic customers to optimize production and thus remain at the forefront of the ever more fiercely contested competition.

Cutting speeds on the ByCut Star increase twice as fast compared to 15 kW and MixGas with sheet thicknesses between 6 mm and 15 mm, and more than twice as fast with thicknesses starting at 20 mm. Piercing times are shorter for sheet thicknesses of 15 mm and above. Sheet metal processors thus benefit from higher productivity at low unit costs, because with 30 kilowatts, the new ByCut Star cuts steel, aluminium and stainless steel precisely and reliably. The 30-kilowatt laser power enables maximum flexibility for large series and spontaneous customer orders. Whether aluminium or steel, the powerful Bystronic cutting head impresses with maximum precision in thin and thick sheets. In addition, with the “Advanced Applications” option, high laser power (starting from 15 kilowatts) now also enables expanded applications in steel and aluminium of up to 50 millimetres. The new power level is exclusively available on the ByCut Star 4020.

Smart features make the difference

NCT & KerfScan is a smart feature package for oxygen cutting which increases process reliability, even in low-manned operations. This feature offers process monitoring, problem solving and continuation of the cutting process in a fully automatic way.

The “Parameter Wizard” ensures that the correct quality of the cut parts is always selected within minutes. This feature determines the perfect parameters with N2 and MixGas for steel from 4 to 15 mm in thickness.

Intelligent Cutting Process ICP is a new feature, where a coaxial camera is filming through the nozzle and looking directly into the cutting process. This feature currently offers the following functionalities:

- Cut Quality Detection – The system automatically detects cut interruptions during the cutting process and re-cuts the area where it occurred.

- Cut Quality Protection – AI-controlled cutting process maintains reliable quality throughout low manned production.

- Nozzle Loss Detection – Down time and material waste caused by nozzle loss are significantly reduced.

While Bystronic customers benefit from outstanding cutting results with clever features, the new powerful Bystronic flagship is also controlled from a 21.5-inch touchscreen. Handling is as simple as operating a smartphone.

The new ByCut Star’s modern, sharp contours provide a striking appearance and match the performance of the machine.

Significantly increased user-friendliness and outstanding flexibility are major advantages provided by the new ByCut Star. Thus, there is front and/or side access as well as several windows with a view directly to the cutting process. In general, the new design offers better accessibility to the interior, and the machine is easier to place on the store floor thanks to more flexible layout.

Fiber laser cutting with mixed gas ensures better cutting quality and higher productivity

In laser cutting, cutting gas (especially N2 and MixGas) is used to keep both the laser and the sheet free of impurities and remove molten material. Nitrogen is used for so-called fusion cutting and oxygen for flame cutting. Gas mixing combines the benefits of O2 and N2 and thus is an alternative to pure nitrogen or oxygen cutting. Cutting with MixGas (a specific blend of Nitrogen/Oxygen) ensures perfect quality on steel at increased cutting speed. This helps even an inadequate steel to achieve a good result after the cutting process.

For in-house gas production with a N2 generator, Bystronic has a solution ready that is attractive from a cost perspective and environmentally friendly. The advantages are obvious: There is no need for transports by trucks when gas is delivered. One produces only as much nitrogen as is needed, and all the previous additional costs are eliminated – from filling the cylinders to replacing them. The sheet metal processor works completely autonomously and – independent from any gas supplier – is doing something for the environment in the process.

For more information please see www.bystronic.co.za or contact Bystronic on 010 410 0200.