SA CAR MAKER RETIRES TONGTAI VERTICAL LATHES AFTER 23 YEARS OF DEDICATED SERVICE

By Paul Savides, PBS Machine Tools

First installed in 1999, Tongtai’s vertical lathes were used as a fully automated cell to produce brake discs and brake drums.

These automated lines have run in full production since they were first designed and installed by Tongtai engineers and now they are being re-purposed to continue manufacturing parts; this is part of our commitment to reduce carbon emissions.

Obviously, while reducing carbon emission, the new range of Tongtai machines are vastly improved compared to the lathes installed in 1999.

But how do you improve something that has been so successful? At TIMTOS 2023 recently running in Taiwan, Tongtai has demonstrated the transformation to Green Economy with the help of the digital transformation they have applied since 2018.

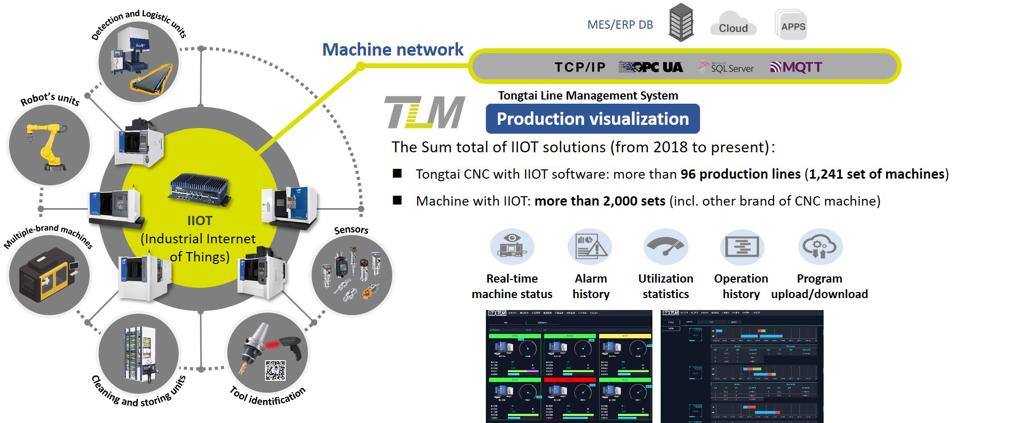

Tongtai’s Line Management (TLM) system is already connected through the Industrial Internet of Things (IIOT) to 96 production lines which include 1,241 machines. Additionally, more than 2,000 machines of different brands are connected via the IIOT.

This is also available with subtractive hybrid machines.

In Tongtai’s endeavour to reach carbon neutral, they have entered into a program to redesign and upgrade the full range of machines.

The first step was to get Carbon Footprint Verification (CFV) so as to understand the technical requirement and regulations and then to assist customers with the process. This has enabled Tongtai to achieve 21.51% in energy saving performance and reduce carbon footprint by 23.19%.

It was achieved with a variety of functions including additive manufacturing, power consumption monitoring, carbon conversion, digital twin solution and energy saving modes built into the machines.

Power consumption monitoring is key in a country like South Africa.

For more information please contact PBS Machine Tools – Tel: 011 914-3360.