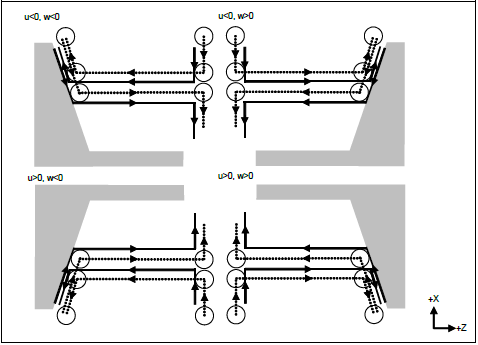

Low cycle time has become increasingly important in recent years. As such, several tool manufacturers have introduced turning tools that support bi-directional cutting. Bi-directional cutting has been used for years using custom machine tool builder or end-user macro programs, to reduce program run time, and then in turn increasing the machine’s output efficiency. FANUC has now added new bi-directional canned cycles, to make the use of this new turning method easier and more efficient, without the need for complicated custom programs.

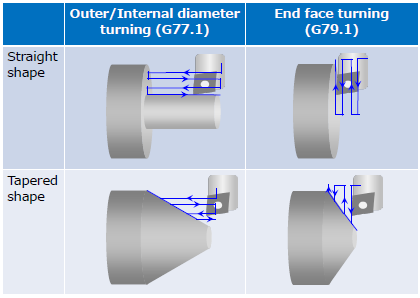

FANUC has introduced two new G-codes specifically to enable the end-user to take advantage of bi-directional tools. Both outer – and internal diameter turning, along with end face turning is now supported with G77.1 and G79.1, respectively. These G-codes allow users to execute bi-directional canned cycles using a single block, this fact also shortens programs significantly, which in turn uses less part program storage space.

Tool nose radius compensation is also supported during bi-directional canned cycles with the offset direction changing, depending on the direction of tool movement, without any additional programming. This again enables the machine to operate more efficiently, with the added benefit of becoming easier to program.

For more information, please contact FANUC South Africa – Tel: 011 392 3610