THE ULTIMATE SOLUTION FOR TUBE PROCESSING

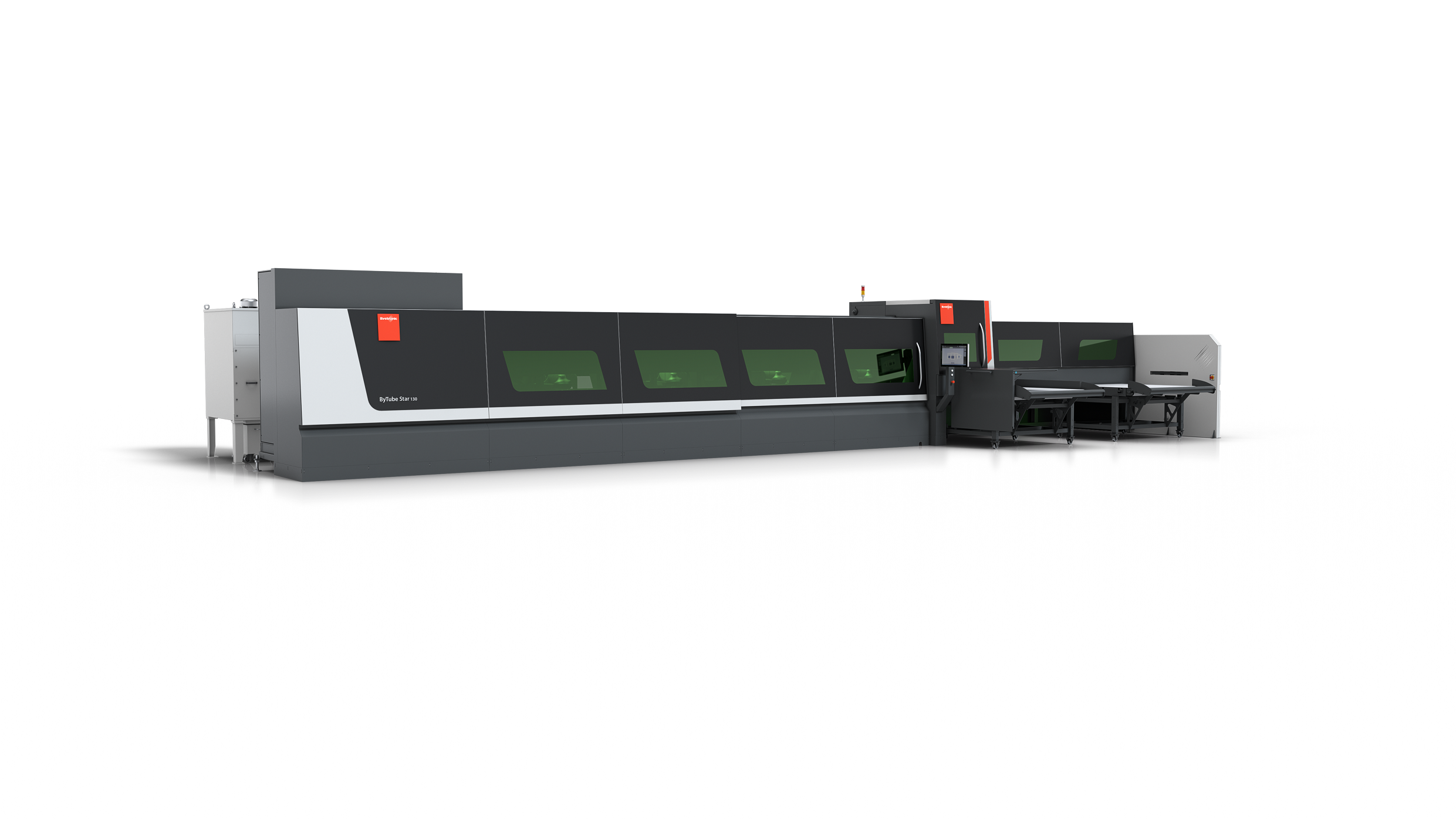

Sheet metal processors accelerate their tube laser business with Bystronic’s new ByTube Star 130, the high-end tube laser with the most features. Accuracy, ease of use, and a fully automatic setup with open profiles and ellipses lead to more flexibility and higher quality in production.

Bystronic supports its customers with solutions that make them even more competitive. Thanks to high-performance machines and optimized processes, they can look to the future with confidence. With the ByTube Star 130 laser cutting system, sheet metal production companies can easily and quickly enter the tube processing business and thus access new customer groups.

Fully automatic setup

With the ByTube Star 130, sheet metal processors who want to expand their portfolio have the perfect solution for tube processing at their fingertips: fast, simple, efficient, and with the most functions. The wide range of applications for all metallic materials in sizes from 10 to 130 millimetres and raw material lengths of up to 8.5 meters opens up new possibilities.

The automated system reduces manual intervention to a minimum, making it particularly easy to get started in tube processing. At the same time, the machine covers an extremely wide range of requirements: Since 85 percent of the market potential lies in the small tube segment, the ByTube Star 130 is geared toward processing tubes with diameters from 10 to 130 millimetres. The machine has a loading capacity of up to 17 kilograms per meter. With the 2D cutting head, 90 percent of all customer requirements can be met, as vertical cuts account for the largest market share.

Available in two power levels, 2 or 3 kilowatts, the fiber laser unit of the ByTube Star 130 impresses with excellent energy efficiency as well as consistently uniform cutting quality.

Additional options increase precision

Additional options can be configured individually and enable further operating convenience as well as increased production quality:

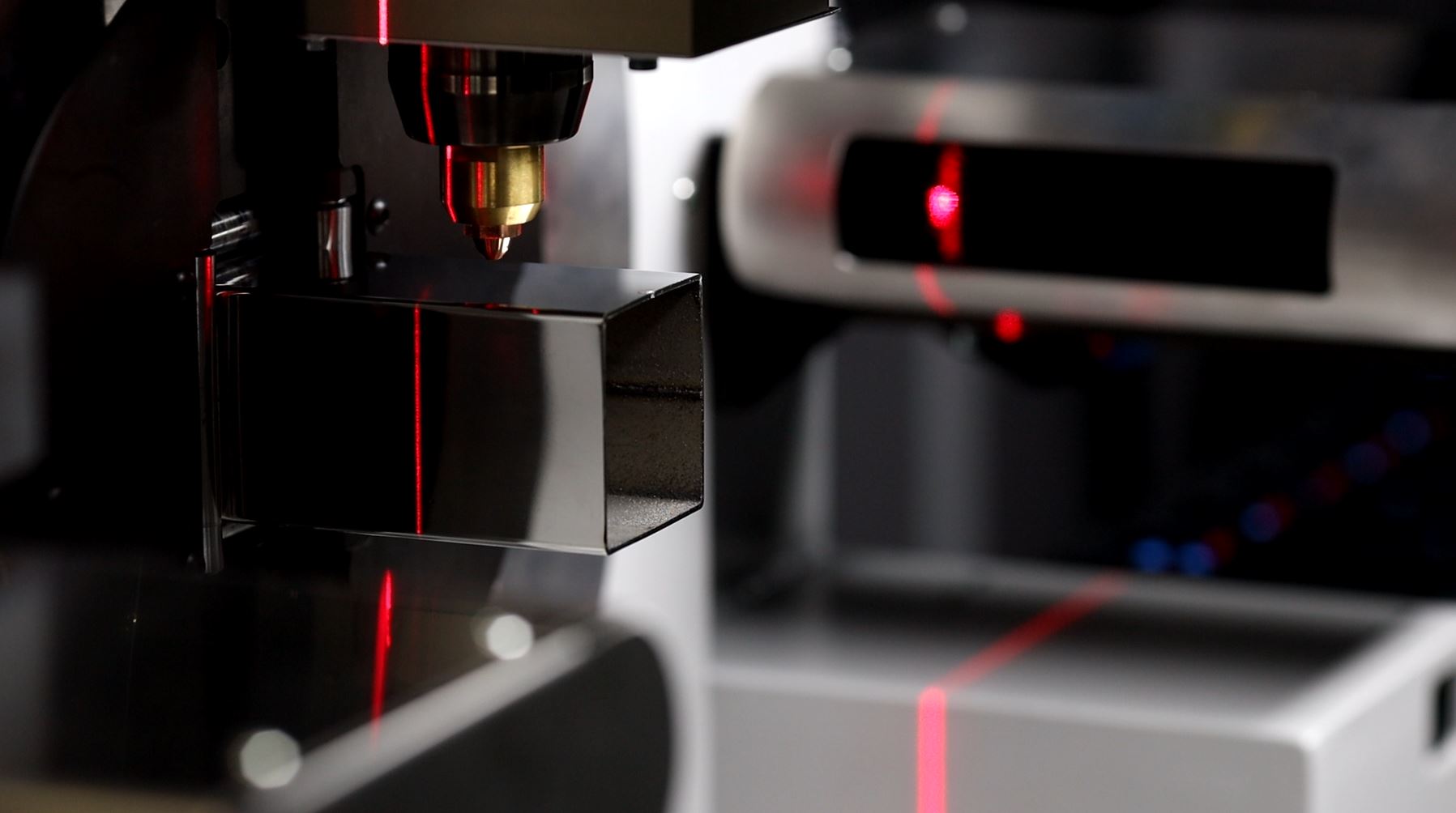

- “Laserscan”: real-time compensation of pipe bending to improve cutting precision, meaning high accuracy is guaranteed in all cutting conditions, even with low-quality material.

- “Quick Cut”: greater speed for better performance thanks to an additional linear axis.

Automatic weld seam detection enables the weld seam to be automatically oriented to the desired position. Via Laserscan, the function independently detects and compensates for geometric deviations of tubes, thus ensuring the accuracy of cutting operations regardless of raw material quality.

Easy and convenient to use

Modern and efficient sheet metal production is no longer conceivable in this day and age without powerful software. With the proven ByVision Tube user interface, Bystronic puts the control of all functions related to the laser cutting of tubes on a touchscreen. Beginners do not need extensive experience to start production on the ByTube Star 130. Cutting jobs are set up quickly, and the interface is intuitive and easy to understand.

ByVision Tube builds on the proven Bystronic software ByVision, which Bystronic uses for all other cutting and bending systems. The intuitive software supports users in importing and creating cutting plans, which makes the operation of cutting sequences on the ByTube Star 130 particularly convenient. Visualizing parts and models, creating cutting plans, monitoring production processes, be they small batches or large orders — thanks to ByVision Tube, users progress productively and quickly from entering orders to delivering finished parts.

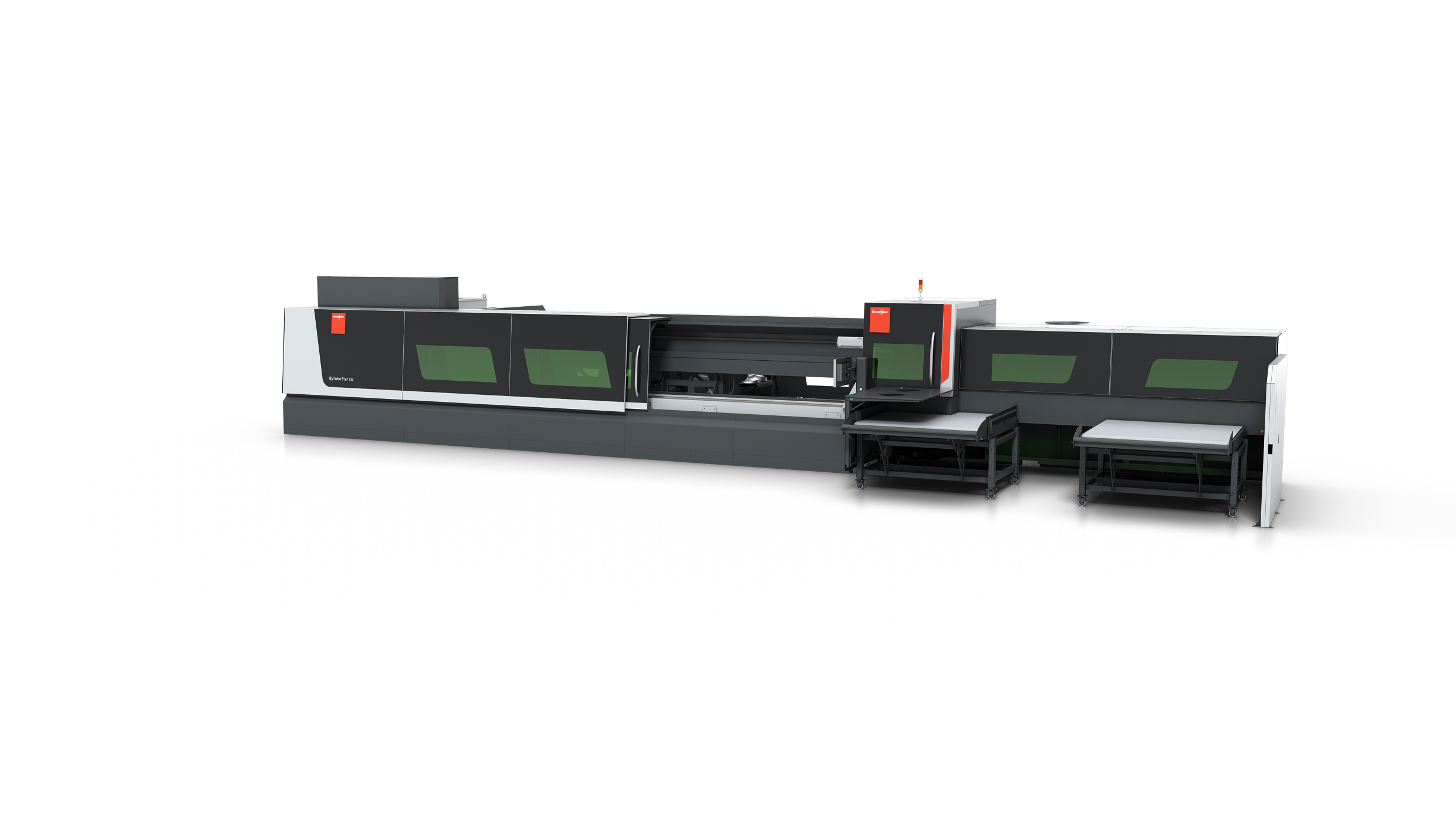

Left or right is irrelevant

As the only supplier worldwide to do so, Bystronic also offers the ByTube Star 130 laser cutting system in a version with a “mirrored” configuration upon request. This enables customers to select the optimal layout for their individual production flow. Though simple at first glance, this “mirroring” presents advantages: Loading and unloading areas no longer get in each other’s way. This not only reduces logistical effort, but also saves space and labour. And thanks to faster throughput times, productivity can be significantly increased.

The ByTube Star 130 combines intelligent machine design and leading cutting technology. Its simple operation, wide range of applications, and sophisticated options ensure that Bystronic customers are always one step ahead of others in ever-tougher competition.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.

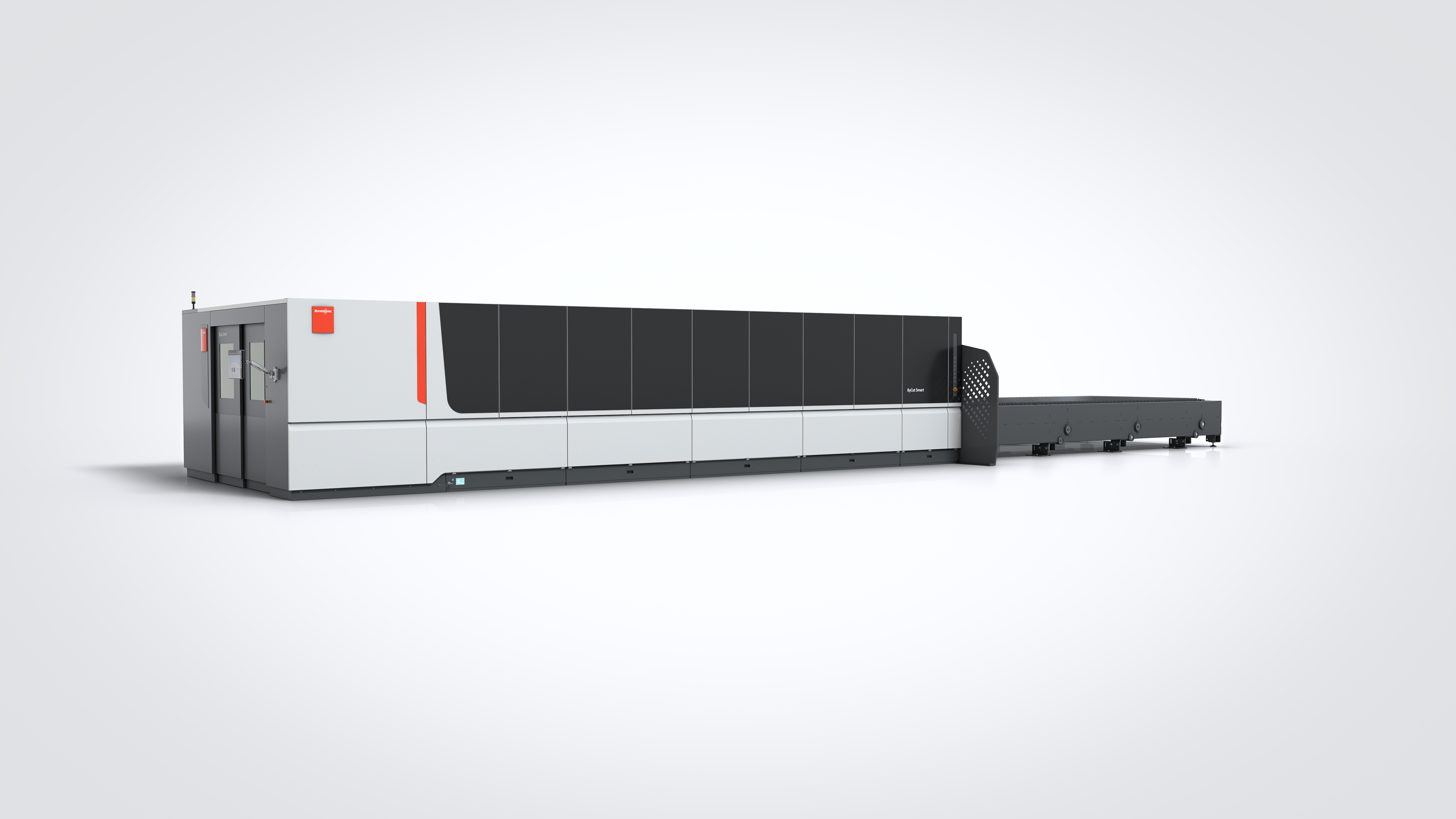

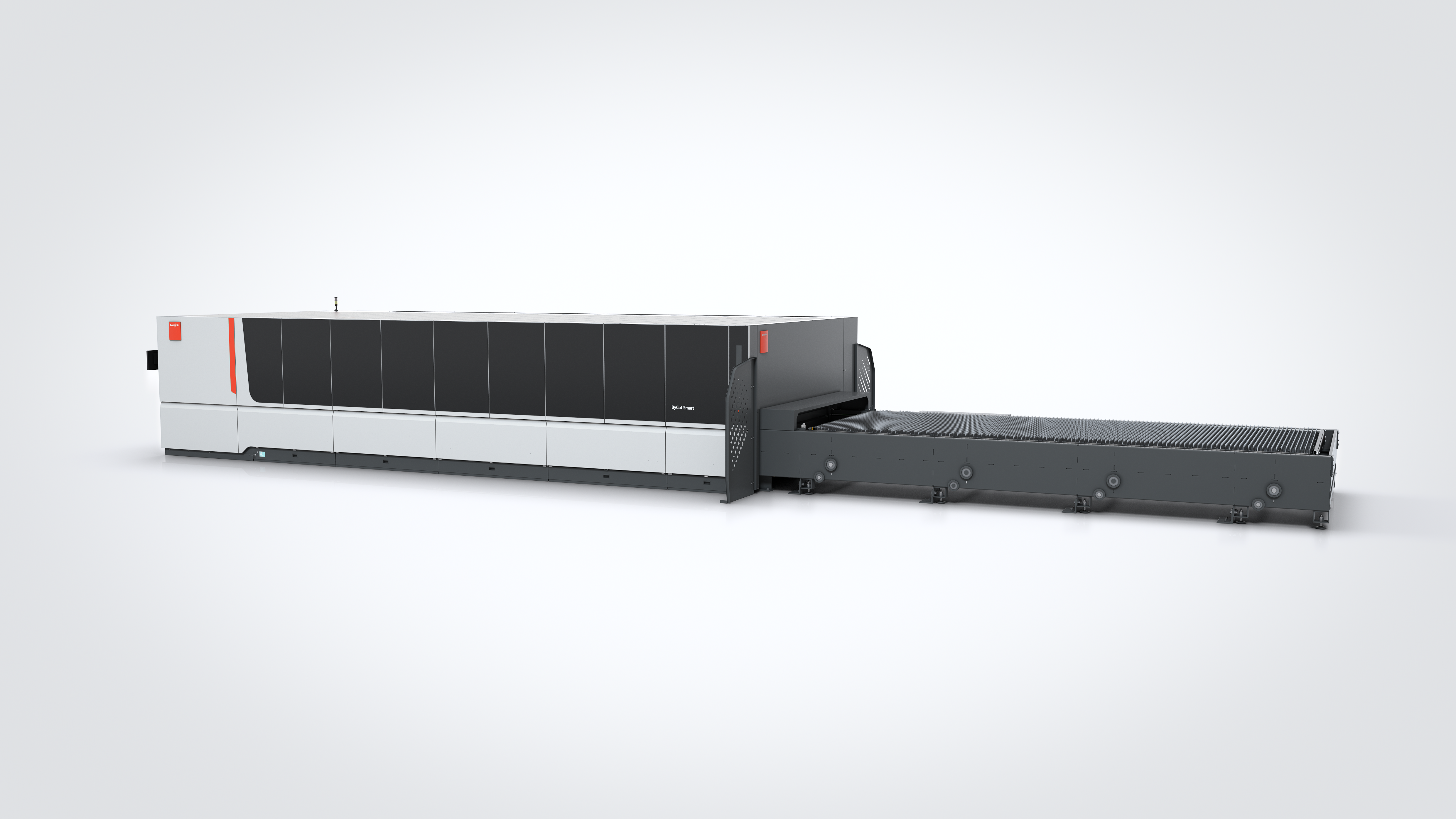

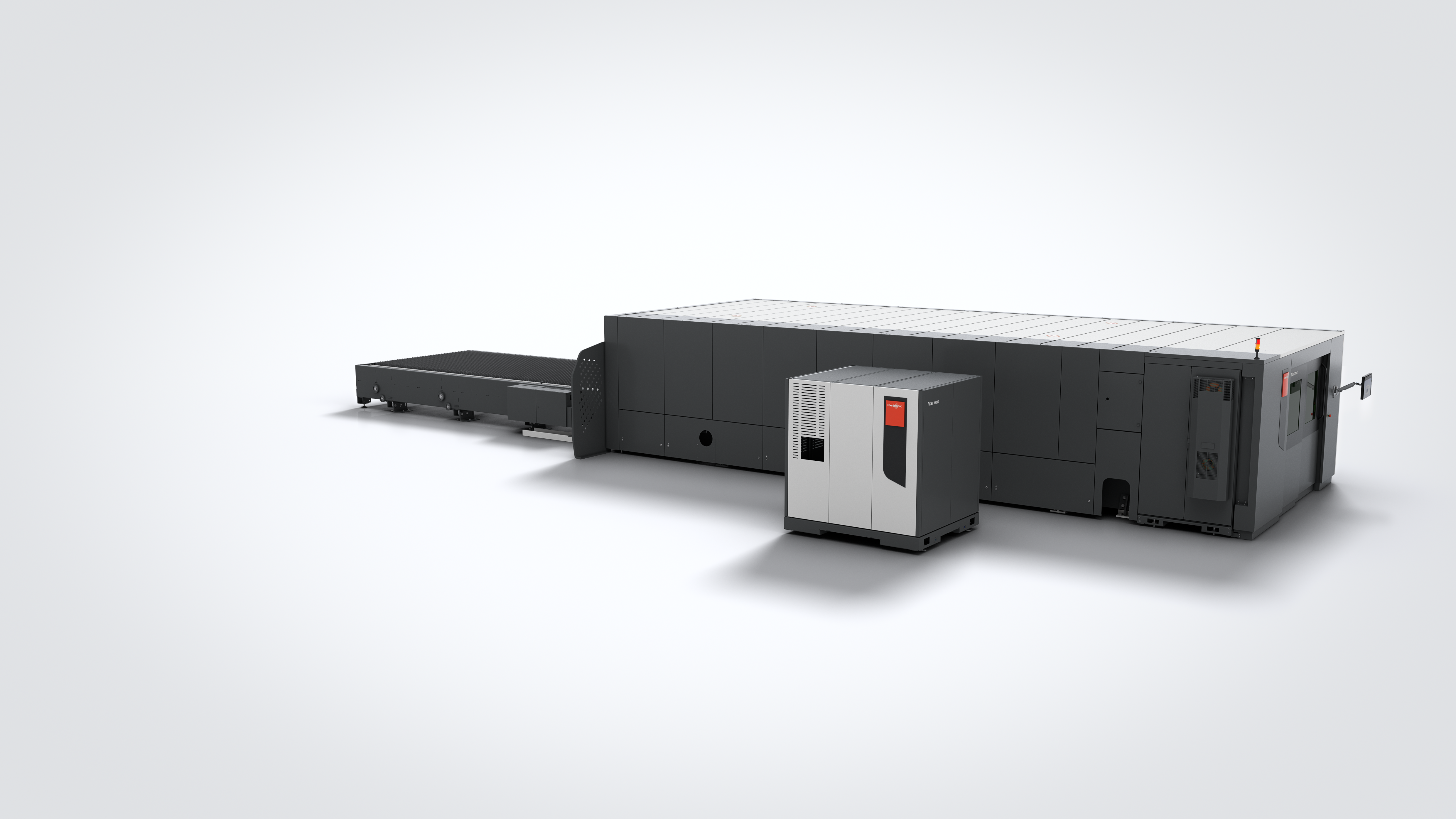

BYCUT SMART 6225 – HIGH PRODUCTIVITY AND PERFORMANCE AT A FAVOURABLE PRICE

More sheet metal, more parts, more variety, and a new design. The latest generation of Bystronic’s ByCut Smart 6225 takes the optimization of sheet metal utilization to a new level thanks to the 6225 cutting format. A laser output of up to 10 kilowatts and the optional BeamShaper are the real highlights of the new system; all this at a favourable price.

More sheet metal, more parts, more variety. Large-format laser cutting systems enable users to stand out against competitors without huge financial expenditures. This is why Bystronic is expanding the ByCut Smart product line with the 6225 format in a new design. The machine can be equipped with the Fiber 3000, 4000, 6000, 8000, or 10000 laser sources, depending on the user’s requirements.

Thanks to the new large format, users can process metal sheets on the ByCut Smart with a length of up to 6.2 meters and a width of 2.5 meters. On the one hand, this increases the machine’s productivity, because large metal sheets allow the cut parts to be nested more efficiently. On the other hand, this also significantly reduces undesirable raw material offcuts thanks to a high degree of material utilization. Apropos, the BySoft CAM process software supports the user in this process with intelligent nesting procedures.

Wide range of cutting applications

In addition, the new format increases the variety of cutting applications on the ByCut Smart. If required, large-format metal sheets allow large parts to be cut in addition to diverse small parts, without requiring the machine to interrupt the laser cutting process. This provides an additional competitive advantage that laser cutting systems in the common standard formats cannot offer.

In addition to cutting applications with extra-large metal sheets, it is also possible to process smaller sheets by lining them up on the ByCut Smart’s long cutting table. Users can simply prepare sufficient raw material, in order to subsequently allow the fiber laser cutting system to cut without interruptions for a longer period of time.

In addition to the ByCut Smart 6225, Bystronic also offers the fiber laser in the 12020, 8020, 6520, 4020, and 3015 formats.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.