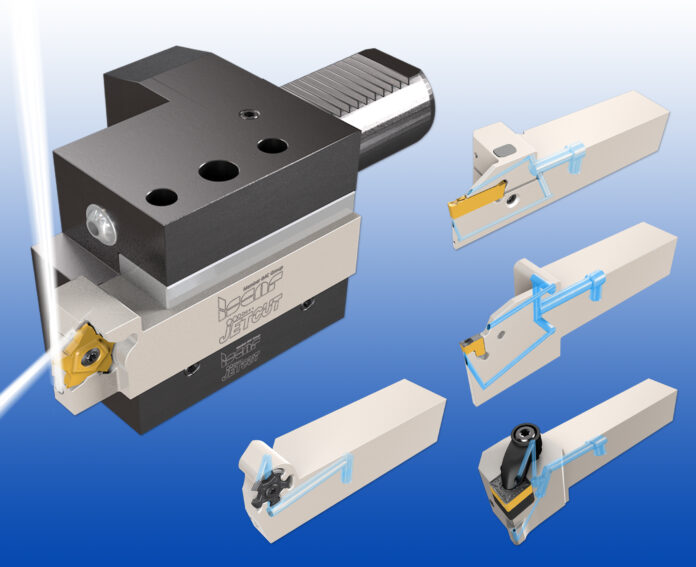

Tools with Bottom Fed High Pressure Coolant Channel for Mounting on VDI DIN69880 Tool Holders

ISCAR is expanding the Multi Connection (MC) JHP Line by adding parting, grooving, threading and turning tools for VDI tool holders with a bottom fed coolant system to ensure efficient coolant supply internally through the tool and externally through the flange. The specially designed system integrates JHP-MC turning and grooving tools featuring a bottom coolant inlet hole, and VDI-JHPMC tool holders with a long coolant outlet slot to enable adjustment of the tool’s overhang.

The compact and light VDI DIN69880 is the most popular quick change adaptation system for CNC turning machines with disc-type turrets. This standard holder adaptation serves mainly stationary turning or drilling tools.

VDI DIN69880 characteristics include high accuracy and center height repeatability, easy and fast set-up, and high stiffness due to a straight shank and flange face contact. Rigidity is facilitated by the serrated clamping system.

The tools are widely used by European, Japanese, Korean, USA, Chinese and Taiwanese machine tool builders, due to their simplicity, low-cost and tool clamping rigidity and have applications particularly in the aviation, aerospace and medical industries.

JHP tools also provide advantageous performance when conventional pressure is applied.

For more information, please contact ISCAR South Africa (PTY) LTD – Tel: 011 997-2700.