The VTX-II series is the latest version of VTX series that belong to the TapMill range of machining centres and are renowned for their high production efficiency and compact floor size.

In this new generation, the VTX-II series provides two models for satisfying different machining demands, namely the high torque type and high efficiency series.

The VTX-II high torque type not only provides the machining torque equal to a medium-sized machining center, but also keeps its originally outstanding rapid traverse performance of 60m/min.

The VTX-II high efficiency type on the other hand has outstanding spindle acceleration/deceleration performance, which provides fast spindle orientation to the tool changing point and dramatically saves cycle time and additionally, making it suitable for tool room applications.

Compared with conventional belt-driven spindle machines, the VTX-II series is standardly equipped with a direct-drive spindle for better rigid tapping performances and furthermore, solving the problem of short usage life of the spindle belt.

The A-shape column design and roller type linear guideway ensure dynamic stability under rapid traverse of 60m/min with the 1.2G acceleration force.

High Torque type

- The new VTX-II high torque type has an 84Nm torque output, and its performance is higher than the conventional tapping centre making it a true, high performance milling centre.

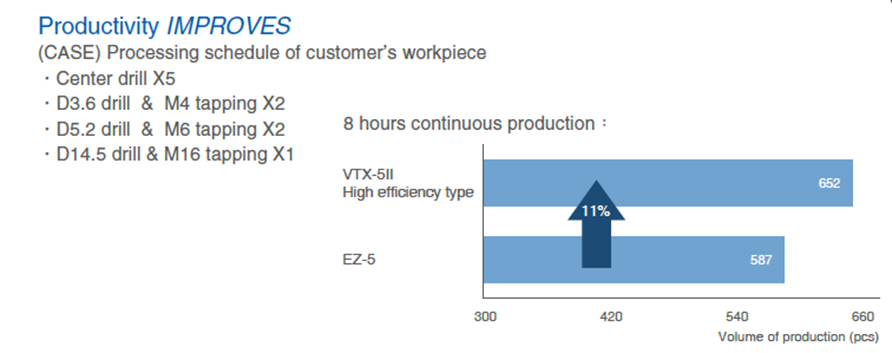

High Efficiency type

- The new VTX-II high efficiency type has a spindle speed of 9,000 rpm making it suitable for high speed machining applications. After a test, the saving in cycle time compared to the previous model is up 11%.

Additional features included in this new range of machines are designed to make them independent of operator skills.

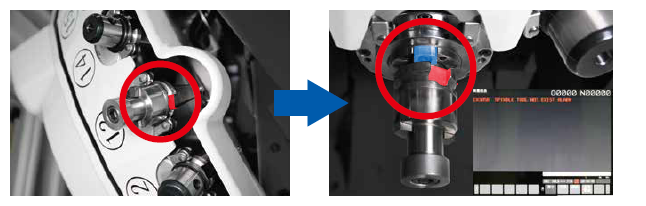

By example, the VTX-II is equipped with a clamping error inspection function to avoid tool damage caused by human operating errors, while guarantying machining quality.

Clamping error inspection

- When the tool doesn’t clamp completely, due to incorrect placement and if the drive block does not locate correctly into the drive slot of the holder, the clamping error inspection function informs the control, which in turn displays an alarm message.

For more information please contact PBS Machine Tools – Tel: 011 914-3360.