The application of processed tubes and profiles is manifold, whether in the automotive industry, furniture design, architecture, petrochemical industry or commercial vehicle construction. In many industries, the laser-assisted processing of tubes and profiles offers an almost unlimited manufacturing spectrum for components and unique design possibilities.

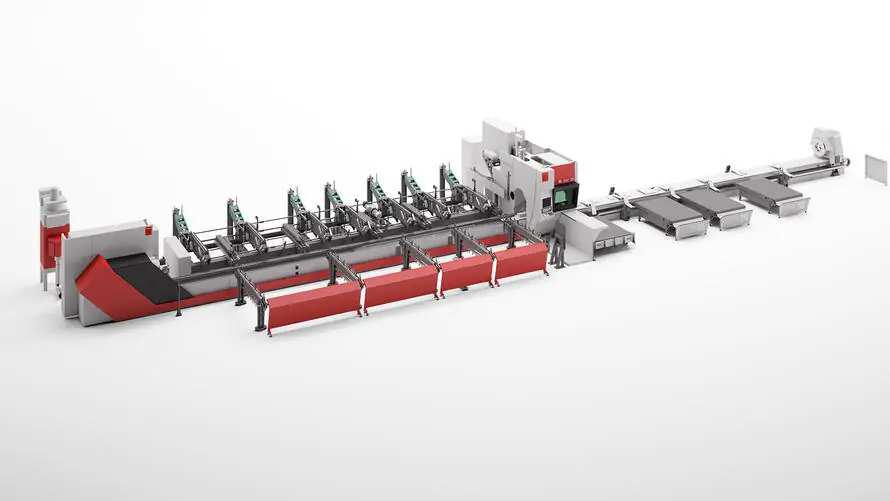

With diameters ranging from 10 to 324 millimetres and pipe and profile lengths up to 12.5 meters, our system solutions offer the largest available selection for the flexible production of small and large series.

CO₂ and fiber laser technology

The right cutting technology for every requirement is important. Depending on the materials that are to be processed and the desired cutting quality and level of productivity, users have the choice between CO2 laser cutting systems and fiber laser cutting systems.

Fiber lasers achieve high cutting speeds in thin material thicknesses. Additionally they boast low power consumption while requiring little maintenance. The special properties of this laser cutting technology enable applications in steel, stainless steel, aluminium and non-ferrous metals, such as copper and brass.

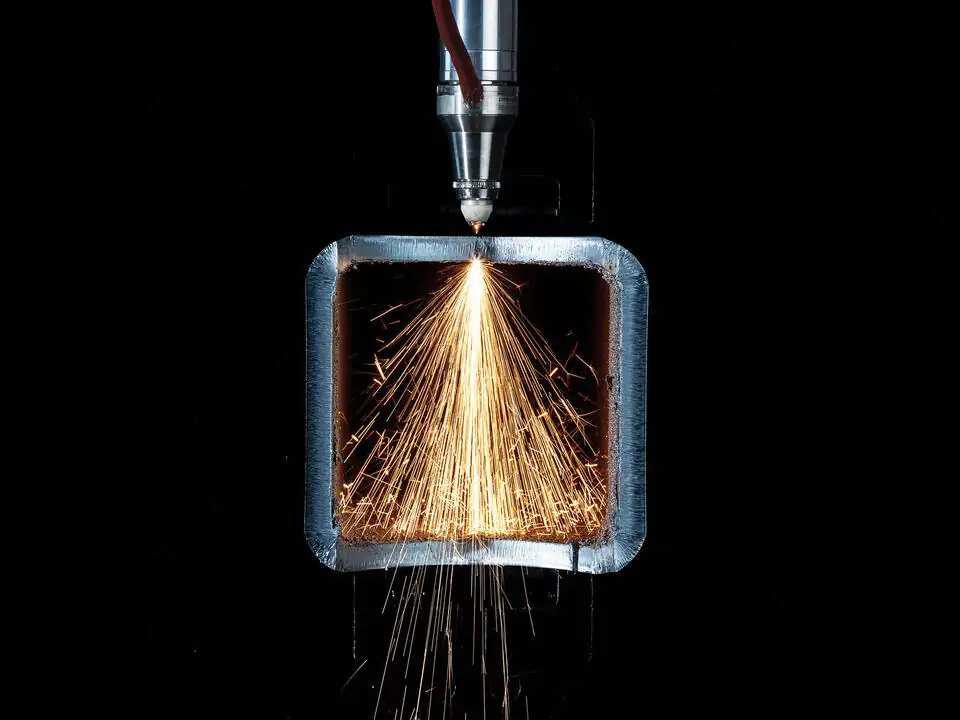

CO2 lasers are characterized by their high cutting quality. Their primary area of application lies in the medium to high range of material thicknesses. The cutting edges achieved with the laser beam excel through burr-free cutting and low scoring. This means that the cut parts can be processed further without reworking.

2D and 3D processing

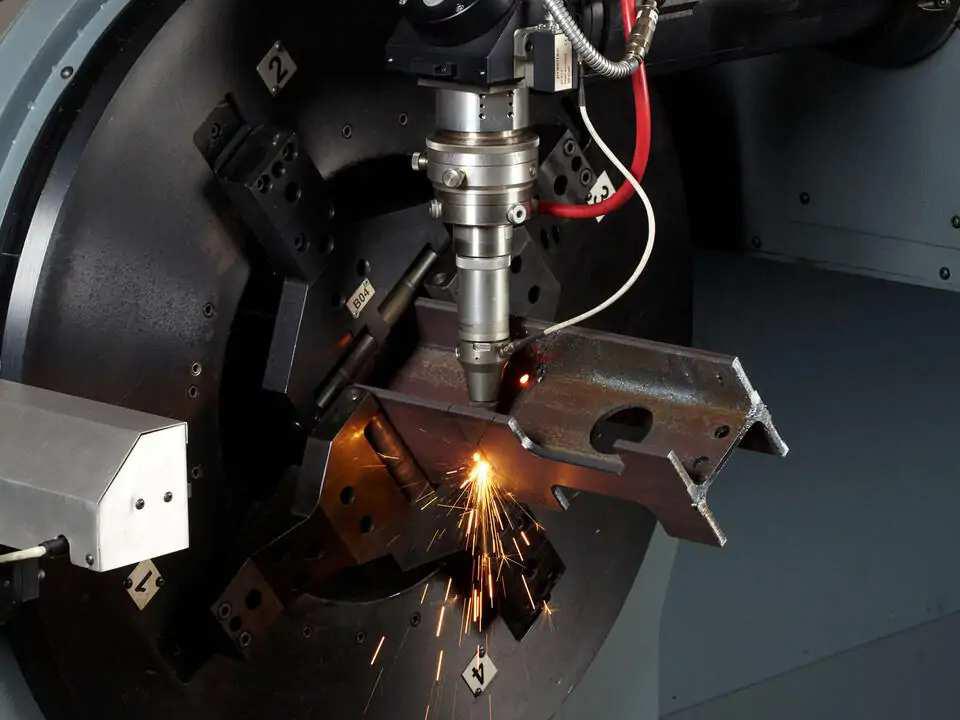

The ability to choose between 2D and 3D laser cutting technology opens up the possibility of individually customized and precise cutting of parts in a very wide variety, such as tubes with round, square, and rectangular shapes as well as profiles with diverse open cross-sections (for example H, L, T, and U cross-sections). In addition to straight cutting edges, the 3D technology also enables bevel cuts up to 45 degrees. This versatility eliminates the need for costly milling, drilling, punching, or sawing processes.

BYTUBE STAR 130 WATCH VIDEO

All you need for your tube laser business is quality and performance in one machine – now also for open sections

- The easiest step into the tube laser process is established technology, user-friendly interface (ByVision Tube) plus one machine which does it all without set up/change over.

- Fully automatic set up also with open profiles and ellipses from 10 to 130 mm full range and for open profiles, no down time for set up, therefore more time for cutting, less human mistakes and more safety for the operators.

- Quick cut performance and quality in just one feature. Additional linear axis of the cutting head for highest speed and quality in all cutting circumstances and quality guaranteed even with very small tubes.

- Laserscan and active tube support during the cutting process with real time compensation of tube bending to improve cutting precision and accuracy also for low quality material and with minor impact on process speed.

- While machine configurations are suitable for all logistics needs, the machine can be left hand or right hand depending on specific flow of the material, resulting in cost reduction thanks to optimization of space and logistic operation.

FL 170 WATCH VIDEO

The fiber laser for fast and versatile applications

Concentrated technology with the cutting system combining the unique benefits of fiber laser technology with the versatility of 3D cutting.

- Wide range of applications for the cutting of steel, stainless steel, aluminium and non-ferrous metals in diameters from 12 to 168 millimetres and workpiece lengths up to 6 meters.

- More profit per part as fast cutting processes are combined with comparatively low operating costs and low maintenance requirements.

- In addition to straight cutting edges, the 3D technology also enables bevel cuts of up to 45 degrees. This versatility eliminates the need for costly milling, drilling, punching or sawing processes.

FL 300

The tube laser for highest demands on productivity and flexibility

FL 300 WATCH VIDEO

- Outstanding cutting quality right up to high material thicknesses: The CO₂ laser technology achieves excellent cutting edges with minimal scoring. In addition to straight cutting edges, the 3D cutting head also enables bevel cuts of up to 45 degrees. This versatility eliminates the need for costly milling, drilling, punching or sawing processes.

- Wide spectrum of applications: Users cut steel, stainless steel and aluminium in diameters between 20 and 324 millimetres and workpiece lengths up to 12 meters.

- Flexible loading from bundle loading or from chain loading system for open profiles is provided, while subsequently, the precise clamping of the tubes and profiles ensures high-precision processing.

- Intelligent unloading increases system productivity and reduces downtime when removing finished parts.

- For longer workpieces, the unloading system’s controllable axes enable any type of tube or profile to be clamped during processing.

For more information on the please see www.bystronic.co.za or contact Bystronic on 010 410 0200.