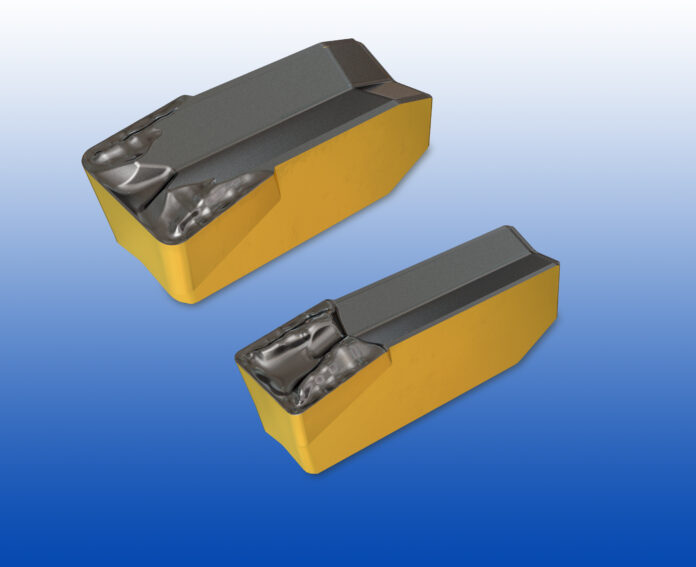

ISCAR’s new groove-turn chipformers for CUTGRIP GIMT pressed inserts are optimized for four applications, such as grooving, partial grooving, turning and finish turning. Most chipformers available on the market perform well in one or two of the above-mentioned four applications but very rarely in all of them.

Based on ISCAR’s accumulated experience and intensive R&D, the GIMT excels in all four applications, providing efficient chip control in a wide range of machining conditions. The GIMT inserts were optimized for steel materials but they also function very well on stainless steel and high temperature material groups.

The GIMT inserts are available in standard widths of 3, 4, 5 and 6 mm.

The new inserts provide a high-performance and cost-effective solution that can eliminate the use of different insert types for each application, reduce stock requirements and provide end users with higher flexibility.

Chipformer elements include a side-turning land with constantly varying rake angle for better chip formation, variable width in the frontal land for earlier chip control at low feed rates, a wave-contoured deflector, an optimized radius area for excellent chip control in small ap for both partial grooving and finish turning and, for 5 and 6 mm widths only, an “F” style frontal deflector for improved chip control in full width grooving.

For more information, please contact ISCAR South Africa (PTY) LTD – Tel: 011 997-2700.