A SUPER FACTORY

Bodor Laser, a huge manufacturer based in Jinan, the capital of eastern China’s Shandong province and a forerunner in the ultra-high-power field of the global laser cutting industry impresses visitors with a white floor and at almost 30,000 square meters, the largest laser cutting equipment production workshop in the world. Bodor’s R&D center is staffed with more than 100 top researchers, and millions of dollars are invested in R&D projects each year.

Bodor Laser, a huge manufacturer based in Jinan, the capital of eastern China’s Shandong province and a forerunner in the ultra-high-power field of the global laser cutting industry impresses visitors with a white floor and at almost 30,000 square meters, the largest laser cutting equipment production workshop in the world. Bodor’s R&D center is staffed with more than 100 top researchers, and millions of dollars are invested in R&D projects each year.

While production strictly meets European standards and international quality control, the company also leads the high laser power laser machine sector, with the first 30kw laser cutter and the first 40kw laser machine launched recently. To date the company has almost 700 12kw machines and over 40 20kw machines installed all over the world.

The Bodor product portfolio includes high power laser cutting machines, fiber laser metal sheet cutting machines, high precision laser cutting machines, metal sheet and tube laser cutting machines, sheet cutting automation devices and coil laser cutting machines.

In 2019, Bodor Laser completed its 25kW and 30kW global debut, becoming a weather vane for ultra-high power laser applications in the industry.

The Bodor Laser 40kW ultra-high power fiber laser cutting machine made its global debut at the Bodor Laser Innovation and Research Center a few months ago. Now, the world’s first 40kW laser cutting machine is redefining laser cutting.

During a press conference, Mr. Yang Xuguang, General Manager of Bodor Laser Research and Development said, “The ability of 40kW laser cutting breaks through the bottleneck of cutting thickness and creates new standards. With the all-round upgrading of cutting thickness, cutting accuracy and cutting speed, Bodor Laser 40kW makes more laser applications a reality and becomes a new benchmark in the laser cutting industry.”

“While the maximum cutting thickness of Bodor Laser 40kW can reach 200mm, the comprehensive processing efficiency of Bodor Laser 40kW is increased by 50%- 80%, the cutting of 20mm carbon steel can reach 6m/min and 30mm carbon steel can reach 2.4m/min.

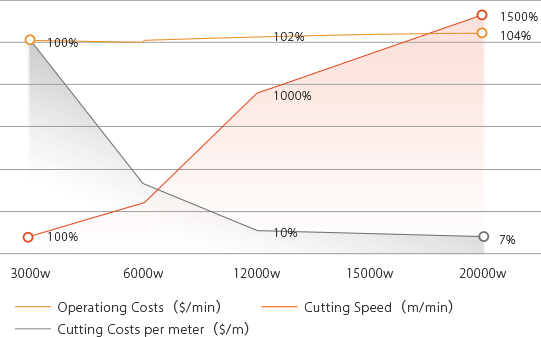

Faster Cutting Speed + Less Costs = More Profit

This chart shows the trend of machine operating costs, cutting costs per meter and the cutting speed when cutting 10mm stainless steel. From 3kW to 20kW as you see, the cutting speed becomes faster and cutting costs lower as the power grows. However, operating costs in the same condition change rather stably. Comparing 12kW with 3kW in the chart, for example, the data shows you that operating costs increase only by 2% under 12kW, but prominently, the cutting speed increases by 10 times, and cutting costs are only one-tenth of a 3kW machine.

For more information, contact Bodor – Email: Pauline.xu@bodor.com or Tel: +86 186 6039 2325.