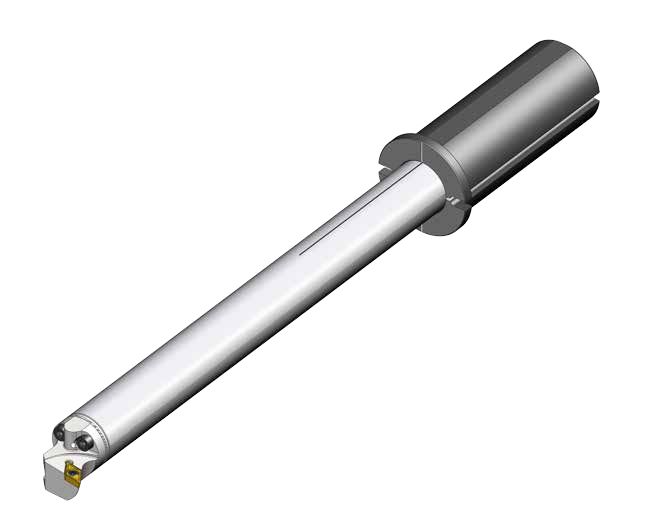

HUSH-BORE – VIBRATION FREE BORING BAR LINE WITH EXCHANGEABLE HEADS

Machining depth in internal turning differs according to the shank materials of bars used, while steel boring bars are used up to 3XBD (bar diameter) and carbide boring bars up to 5XBD. Deep internal turning, however, is very difficult to machine even with carbide boring bars. With the HUSH-BORE’s damping system, TaeguTec has provided an internal turning solution up to 10XBD.

The HUSH-BORE’s damping system located inside the shank is capable of deep internal machining more than 5XBD, this dramatic damping capability enables very good surface roughness of the workpiece and results in longer tool life and stable machining. It also means increased feed and cutting speed, making it more productive.

Shanks for the HUSH-BORE line are available as standard items in 7 different diameters (Ø16, 20, 25, 32, 40, 50, 60 mm) and in 2 lengths (7XBD, 10XBD). The various exchangeable heads can be securely fastened with serrated couplings located in the boring bars.

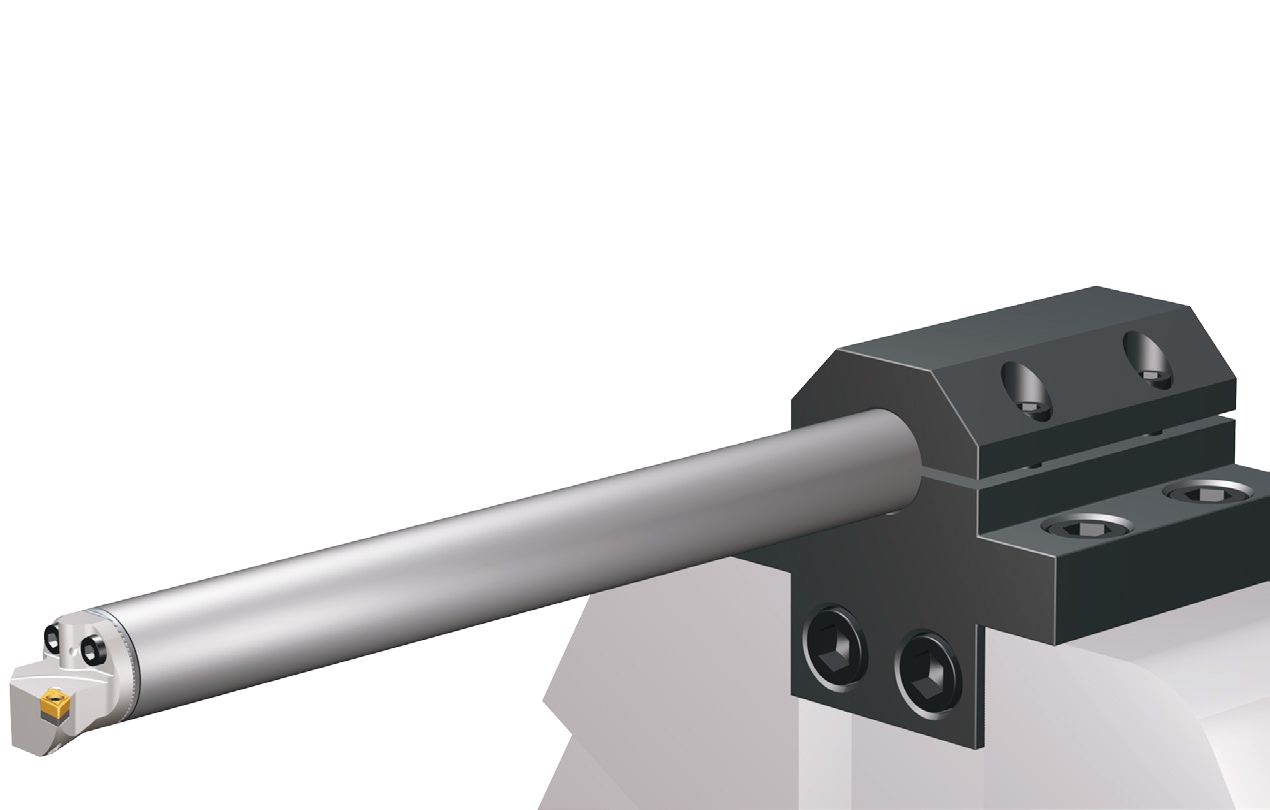

TAEGUTEC HUSH-BORE SLEEVE

Vibration free HUSH-BORE boring bars are cylindrical shank type products with no flat parts for deep internal turning operations in 7xBD to 10xBD (BD: shank diameter) range. Therefore, based on the flat surface design of the head, set-up time can become an issue.

To solve this issue, TaeguTec has launched HUSH-BORE sleeves that can be easily set up in the machine’s toolholder.

These specific sleeves with one-sided slit maintain a robust clamping force and high precision because of its wide contact area when combined with the new HUSH-BORE shank. First, gently tighten the flat surface onto the sleeve with a screw onto the holder. Second, match the HUSH-BORE’s shank line with the sleeve-line. Third, check the zero setting with the dial gauge, ensure it is within ±0.01 mm. Fourth, secure the sleeve by screwing tightly to the tool holder, thereby promoting easier, faster setting time with better accuracy.

For more information please contact TaeguTec – Tel: 011 362-1500.