Visit TaeguTec

Carbide Shank for Small Size M06 Modular Type End Mills

TaeguTec’s T-FLEXTEC line recently introduced a M06 type carbide shank for small size modular end mills. This carbide shank is highly rigid and very effective in preventing vibration while enabling stability in deep depth of cut operations. This results in an increased feed rate during operation, thus allowing for higher productivity. A further benefit to the M06 type shank is great chip evacuation due to the internal coolant channel.

This carbide shank is highly rigid and very effective in preventing vibration while enabling stability in deep depth of cut operations. This results in an increased feed rate during operation, thus allowing for higher productivity. A further benefit to the M06 type shank is great chip evacuation due to the internal coolant channel.

The M06 modular end mill’s shank is available in both Ø10 and Ø12 sizes. As it enables stable machining for small diameter holders, the carbide shank can be applied to both roughing and finishing applications.

The M06 modular end mill’s shank is available in both Ø10 and Ø12 sizes. As it enables stable machining for small diameter holders, the carbide shank can be applied to both roughing and finishing applications.

TAEGUTEC APEXMILL

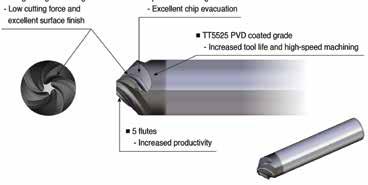

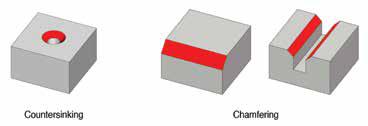

45° CHAMFERING SOLID END MILL WITH 5 FLUTES AND HIGH HELIX ANGLE

TaeguTec recently expanded its chamfering solid end mill line by adding to the current uncoated two and four flute straight cutting edge APEXMILL family. The new end mill not only reduces the cutting force during machining due to its high helix cutting edge, but also improves productivity due to the five flutes design. It is also suitable for high-speed machining and increases tool life with the latest coated grade.

TaeguTec recently expanded its chamfering solid end mill line by adding to the current uncoated two and four flute straight cutting edge APEXMILL family. The new end mill not only reduces the cutting force during machining due to its high helix cutting edge, but also improves productivity due to the five flutes design. It is also suitable for high-speed machining and increases tool life with the latest coated grade.

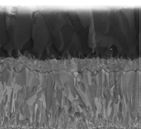

OPTIMIZED CVD COATED GRADE FOR GENERAL PURPOSE, HIGH-SPEED AND HIGH-FEED MACHINING OF STEEL

The new TT8525 grade for milling applications combines an ultra-high toughness substrate with Al²O³+TiCN CVD coating which has excellent wear resistance. This ensures optimal performance for high-speed and high feed machining, as well as general purpose processing of steel. This line of black coloured inserts’ top surface is treated with a state-of-the art coating technology with post treatment that minimizes friction during machining. Thus, it provides excellent stability even in high-speed, high feed machining conditions.

This line of black coloured inserts’ top surface is treated with a state-of-the art coating technology with post treatment that minimizes friction during machining. Thus, it provides excellent stability even in high-speed, high feed machining conditions.

While this new grade replaces the existing TT7800, it has been optimized for high-speed and high-feed machining of steel, ensuring stable tool life with consistent wear in unstable conditions. It is suitable for applications such as roughing and medium, dry and wet machining.

➩ Minimized friction due to the newest

➩ Minimized friction due to the newest

surface treatment technology

➩ Al2O3 layer for better heat resistance

➩ Uniform and stable adhesive layer

➩ TiCN layer for high hardness and high

toughnes

TANG-SFEED LINE NOW AVAILABLE IN ULTRA SMALL 05 SIZE INSERTS AND END MILLS

TaeguTec has introduced a small 05 size insert to the Ø10 (2 teeth) end mill TANG-SFEED product line currently available in 09 and 14 sizes.

Along with the smaller size end mills, two new inserts have been added, including a LPKU 05 utility type and a LPHU 05 precision type. Both inserts along with the end mills, modular head type are available in a 10 to 32 mm diameter range and extended flute end mills in a 16 to 25 mm diameter range.

Along with the smaller size end mills, two new inserts have been added, including a LPKU 05 utility type and a LPHU 05 precision type. Both inserts along with the end mills, modular head type are available in a 10 to 32 mm diameter range and extended flute end mills in a 16 to 25 mm diameter range.

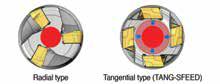

TANG-SFEED product features include a strong tangential type 4-corner insert, exact 90 degree shouldering and optimized geometry for smooth machining and improved stability.

While capable of straight and helical ramping machining, the tangential cutter’s larger diameter core offers a higher stiffness compared to the radial type cutter.

For more information please contact TaeguTec – Tel: 011 362-1500.

Visit TaeguTec