The FANUC Roboshot has 9 models ranging from 15 ton to 300 ton and can be ordered with a wide range of screw diameters and injection speeds which can be selected to best suit your application.

The FANUC Roboshot utilizes the same highly reliable CNC technology that can be found in all FANUC products. As with all FANUC products, the Roboshot is backed by FANUC’s lifetime maintenance policy.

Precision molding repeatability is achieved through the low friction, highly rigid mechanism that utilizes FANUC Servo technology, thus making the machine fully electric driven. This also means that the machine is very economical to run as the servo system uses a regenerative function to conserve power.

Features

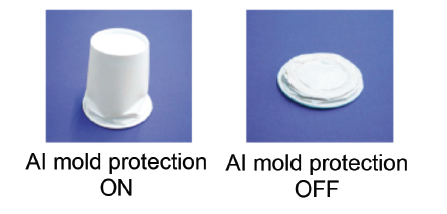

AI Mold Protection is a function designed to protect your mold by monitoring the torque of the servo motor during opening and closing motion of the mold. This allows obstructions to be detected before damage occurs.

This function is also used on the ejector pins to monitor for abnormal ejector condition.

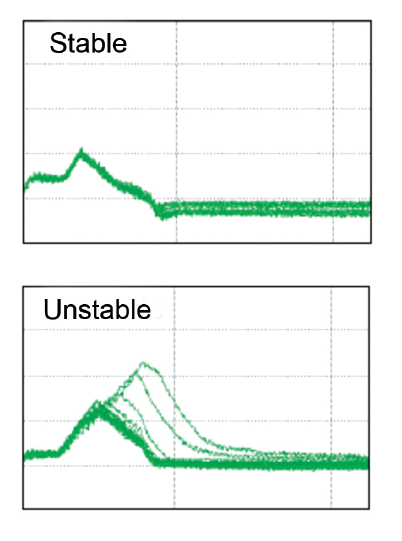

Backflow Monitor Function is used to monitor continuous production to check the stability of the molding process. Minor changes can be made to the settings on-the-fly to adjust stability and the results are displayed graphically on the backflow monitor screen.

Pre-Injection Function can be used to allow gasses to escape through the parting line before the mold fully closes. This allows for faster cycle times and better quality components as mold cavities will have less gas contamination.

Pre-Injection Function can be used to allow gasses to escape through the parting line before the mold fully closes. This allows for faster cycle times and better quality components as mold cavities will have less gas contamination.

The FANUC Roboshot comes standard with Euromap interface for easy connection to picker robots and can be easily connected to FANUC Robots. A hardware and software interface for connecting signal related equipment also comes as standard.

FANUC Roboshot-Linki is a software package that is separately available for the FANUC Roboshot. This allows the monitoring of multiple machines in an automated factory. This software also allows the user to check various statuses, power consumption and production volumes.

FANUC Roboshot-Linki is a software package that is separately available for the FANUC Roboshot. This allows the monitoring of multiple machines in an automated factory. This software also allows the user to check various statuses, power consumption and production volumes.

FANUC also offers a second injection unit on the 50 ton to 150 ton machines for two colour process molding. The SI-20iA unit fits on top of the FANUC Roboshot and the operation screen intergrates onto the Roboshot’s screen offering the same level of accuracy and repeatability.

FANUC Roboshot is made in Japan and comes with a 2 year mechanical and control warranty.

The FANUC Roboshot is available from FANUC South Africa.

For more information, contact FANUC South Africa – Tel: (011) 392 3910