The MC6025 grade utilizes Mitsubishi’s 2 in 1 technology of coating and substrate that merges perfectly to provide the ultimate overall cutting performance.

The smooth surface of the coating prevents chip welding and combines with the Al2O3 and TiCN coating layers to deliver the excellent heat and wear resistance for outstanding tool life during heavy duty cutting. The substrate of MC6025 also uses a new technology that provides a tough outer edge layer for vastly improved resistance to crack development.

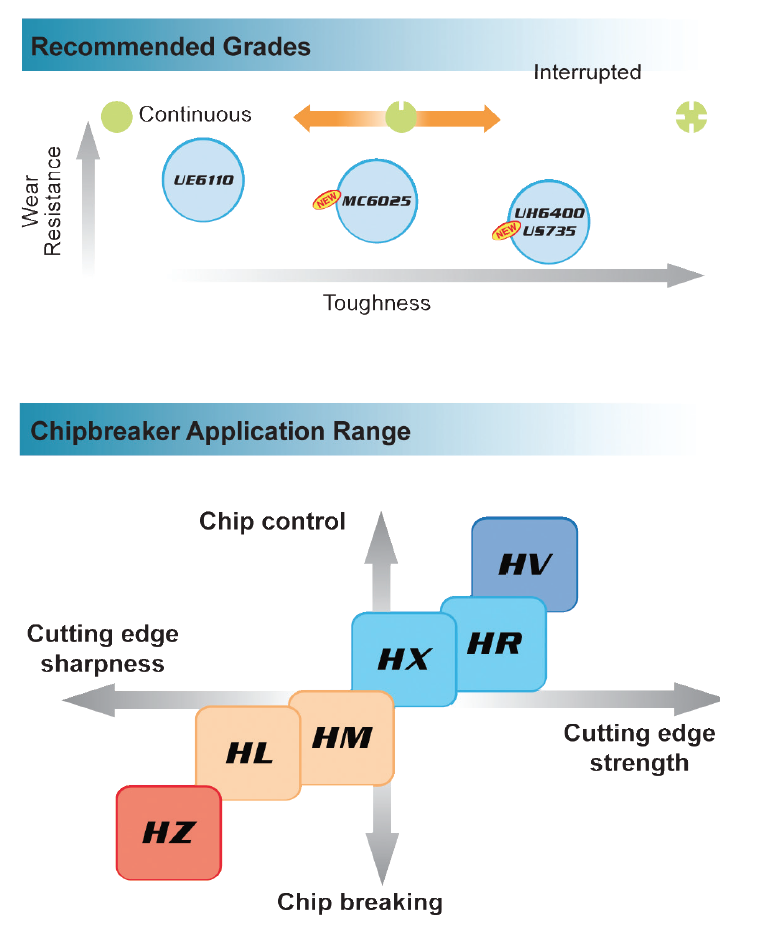

For stainless steels and Nickel based super alloys, the well-known US735 grade has been added to complement the existing grades. The extremely tough carbide substrate of US735 is coated with a specially formulated, thin but tough Ti compound. This compound has super high adhesion strength to ensure it protects the substrate during the extreme conditions faced when turning difficult-to-cut materials.

For stainless steels and Nickel based super alloys, the well-known US735 grade has been added to complement the existing grades. The extremely tough carbide substrate of US735 is coated with a specially formulated, thin but tough Ti compound. This compound has super high adhesion strength to ensure it protects the substrate during the extreme conditions faced when turning difficult-to-cut materials.

Without modern chipbreaking geometries any large enhancements in performance would be difficult. With this in mind, the HR chipbreaker was designed for heavy cutting of general and alloy steels and covers the application area between the existing HX and HV chipbreakers. Compared to the HX breaker, the slightly larger cutting edge land of the HR type provides strength, but with a smooth cutting action. The HR breaker targets outstanding efficiency levels and exhibits good chip control during the high feed rates that are demanded by today’s metal cutting industry.

A large range of standard geometries, including the round type RC and a comprehensive series of chip breakers are available to ensure a huge range of turning applications can be effectively machined with Mitsubishi’s heavy duty insert series.

For more information, contact Multitrade Distributors – Tel: 087 803-2377.